A prediction method for thermodynamic responses and fatigue-creep damage of a high-chrome steel material

A prediction method, a high-chromium steel technology, applied in the analysis of materials, the use of repetitive force/pulse force to test the strength of materials, measurement devices, etc., can solve the model response mechanism is unclear, the material parameters cannot be determined, and the internal variables interact with each other. , simultaneous changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135] The present invention will be described in further detail below in conjunction with specific embodiments.

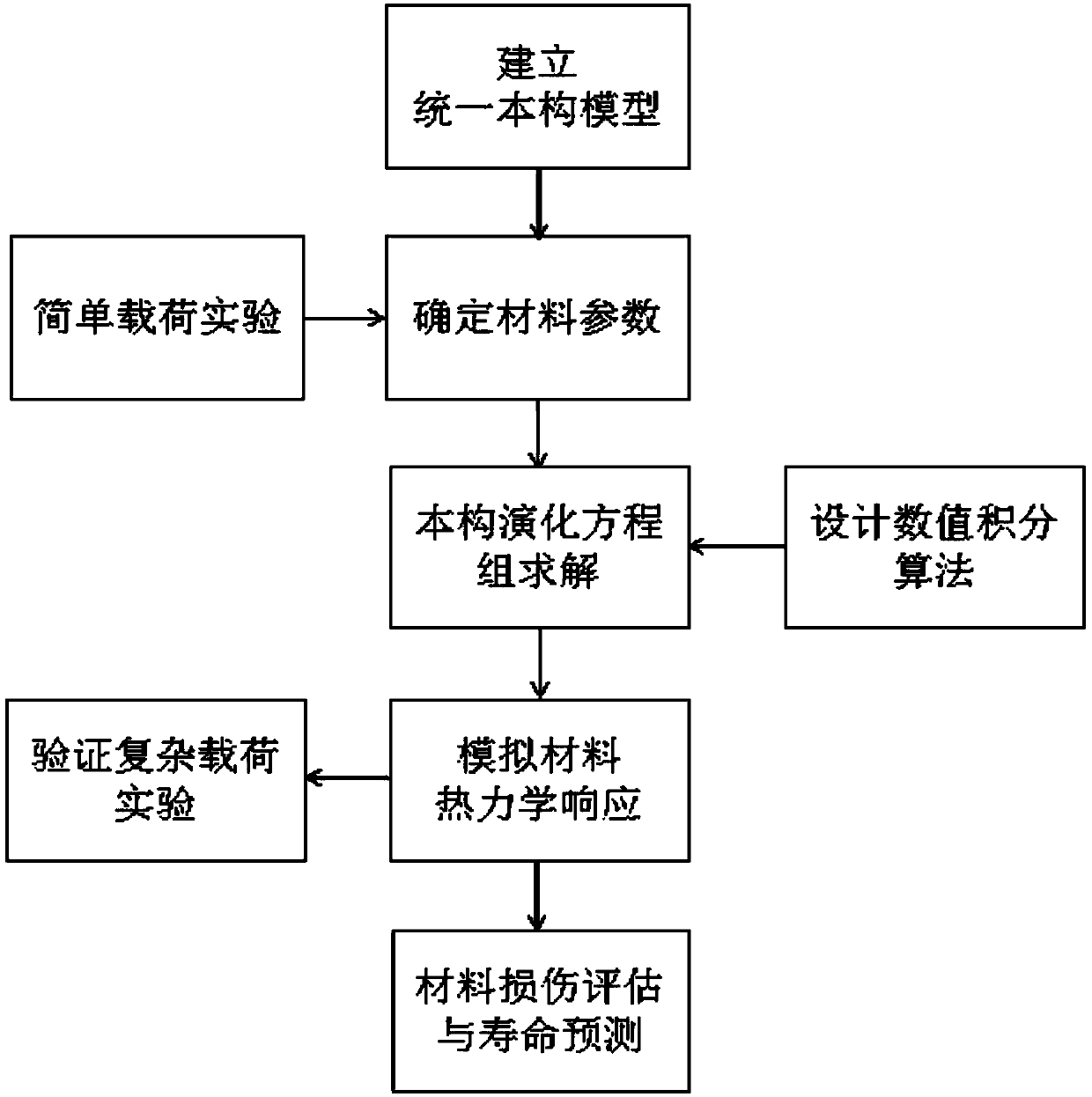

[0136] The invention aims to provide a systematic solution for fatigue and creep deformation prediction and multi-mechanism damage analysis of high chromium steel materials. The content of the program includes the establishment of theoretical models, the determination of material parameters, the design of numerical integration algorithms, and the damage analysis of components. The program will pass figure 1 The implementation of the technology roadmap shown specifically includes the following steps:

[0137] 1) Based on the nonlinear viscoelastic-plastic theory, establish a unified constitutive model for high-chromium steel materials at high temperatures, simulate the local thermodynamic response of the material during the entire loading process, and at the same time fatigue, creep and their interactions Analyze the damage caused. The theoretical model establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com