Seed suction hole blowing mechanism in precision seeding production line

A precision seeding and assembly line technology, applied in the field of agricultural machinery, can solve the problems of consuming a lot of labor, manpower, unable to meet production needs, unfavorable periodic management, etc., to achieve a simple and reasonable structure, ensure normal sowing, and facilitate ash removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

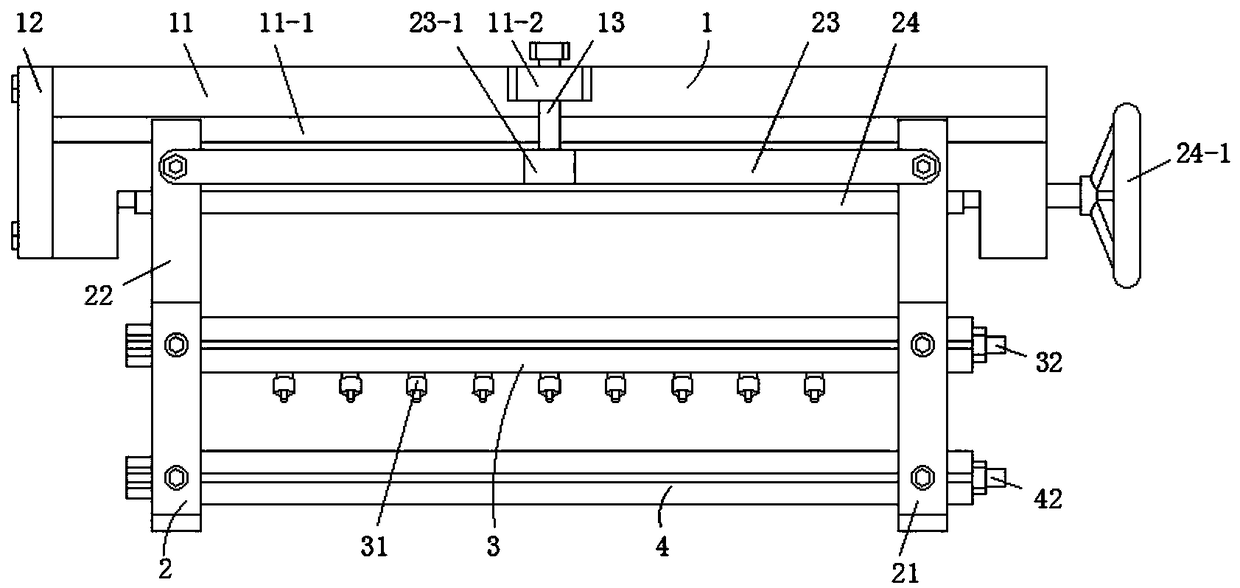

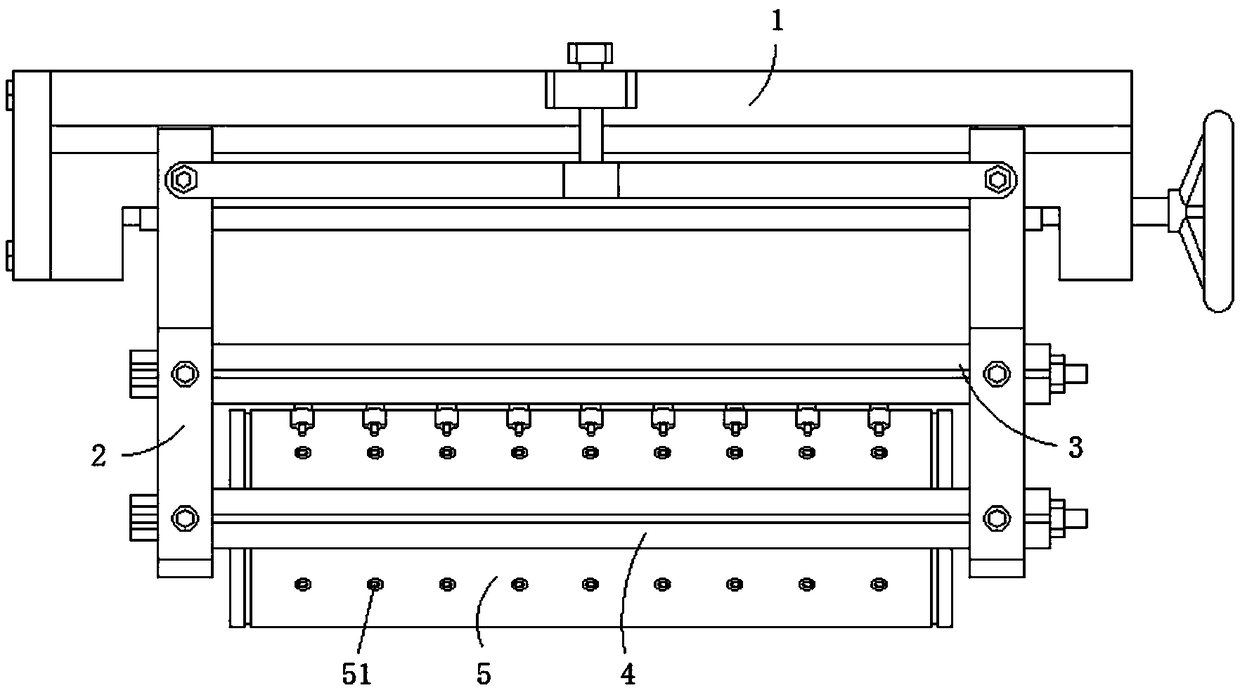

[0029] The seed-suction hole blowing mechanism in the precision seeding assembly line of the present invention can quickly clean the seed-suction holes, and a number of seed-suction holes 51 are uniformly distributed along the circumference of the seed-suction drum 5, and the seed-suction drum 5 is adsorbed by negative pressure. If the seed is in the seed suction hole 51, and then the seeds are released for sowing by releasing the pressure, the No. 1 blowing pipe 3 and the No. 2 blowing pipe 4 are respectively connected to the trachea at No. 1 pipe joint 32 and No. 2 pipe joint 42 positions, which can pass through Inject pressurized air, the No. 1 air nozzle 31 evenly distributed on the No. 1 air blowing pipe 3 corresponds to the seed suction hole 51 at the corresponding position on the seed suction drum 5, and the uniformly distributed No. 2 air blowing pipe 4 on the same The No. 2 air nozzle 41 is also one-to-one corresponding to the seed-suction hole 51 of the corresponding ...

Embodiment 2

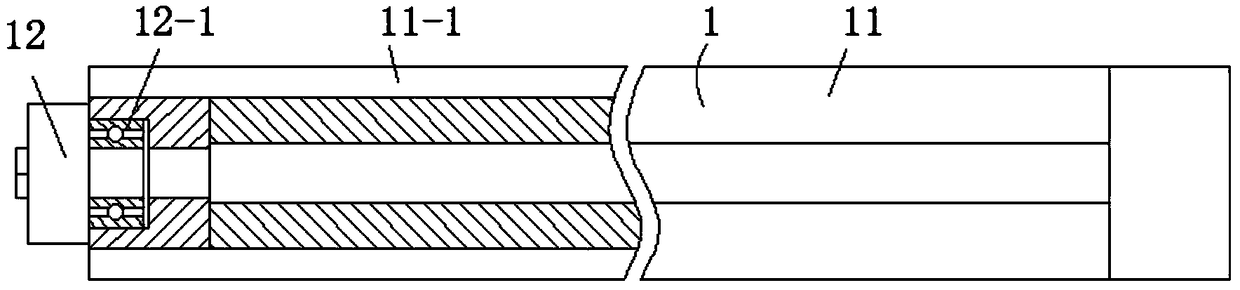

[0031] The seed suction hole blowing mechanism in the precision seeding assembly line of the present invention facilitates the cleaning and disassembly of the seed suction drum 5. When the dust in the seed suction drum 5 accumulates to a certain extent, the seed suction must be regularly Rotating drum 5 is used for dust cleaning, and No. 1 fixed plate 21, No. 2 fixed plate 22, No. 1 air blowing pipe 3 and No. 2 air blowing pipe 4 are all located above the seed suction drum 5, which block the seed suction drum 5. At this time, the limit screw 13 can be loosened from the internal thread seat 23-1 first, and then only the turntable 24-1 needs to be rotated, so that the turntable screw 24 will drive the No. 1 fixed plate 21 threadedly connected with it, thereby driving the entire sliding assembly. Rack 2 goes to the left along the chute 11-1 (to the left is for figure 1 In terms of) sliding, that is to drive the sliding installation frame 2, the No. 1 air blowing pipe 3 and the No...

Embodiment 3

[0033] The seed suction hole blowing mechanism in the precision seeding assembly line of the structure of the present invention has a fast assembly and positioning structure, because no matter whether it is the No. 1 air nozzle 31 or the No. 2 air nozzle 41, it needs to be aligned with the corresponding position on the seed suction drum 5 one by one. position of the suction hole 51, so when assembling the mechanism, it is necessary to consider the rationality of the assembly position, and the end of the No. 1 blowing pipe 3 is a regular hexagonal shape, and there is a step at the transition. The hexagonal end of the blowing pipe 3 is assembled into the No. 1 hexagonal hole 22-1, and the step end surface is in contact with the No. 2 fixing plate 22. The No. 2 blowing pipe 4 has the same structure and can be assembled into the No. 2 hexagonal hole 22 In -2, the limit screw 13 is screwed into the internal thread seat 23-1 at last, and quick positioning assembly is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com