Self-washing pre-filter

A pre-filter and self-cleaning technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve problems such as inconvenience, avoid filter deformation, reduce friction, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

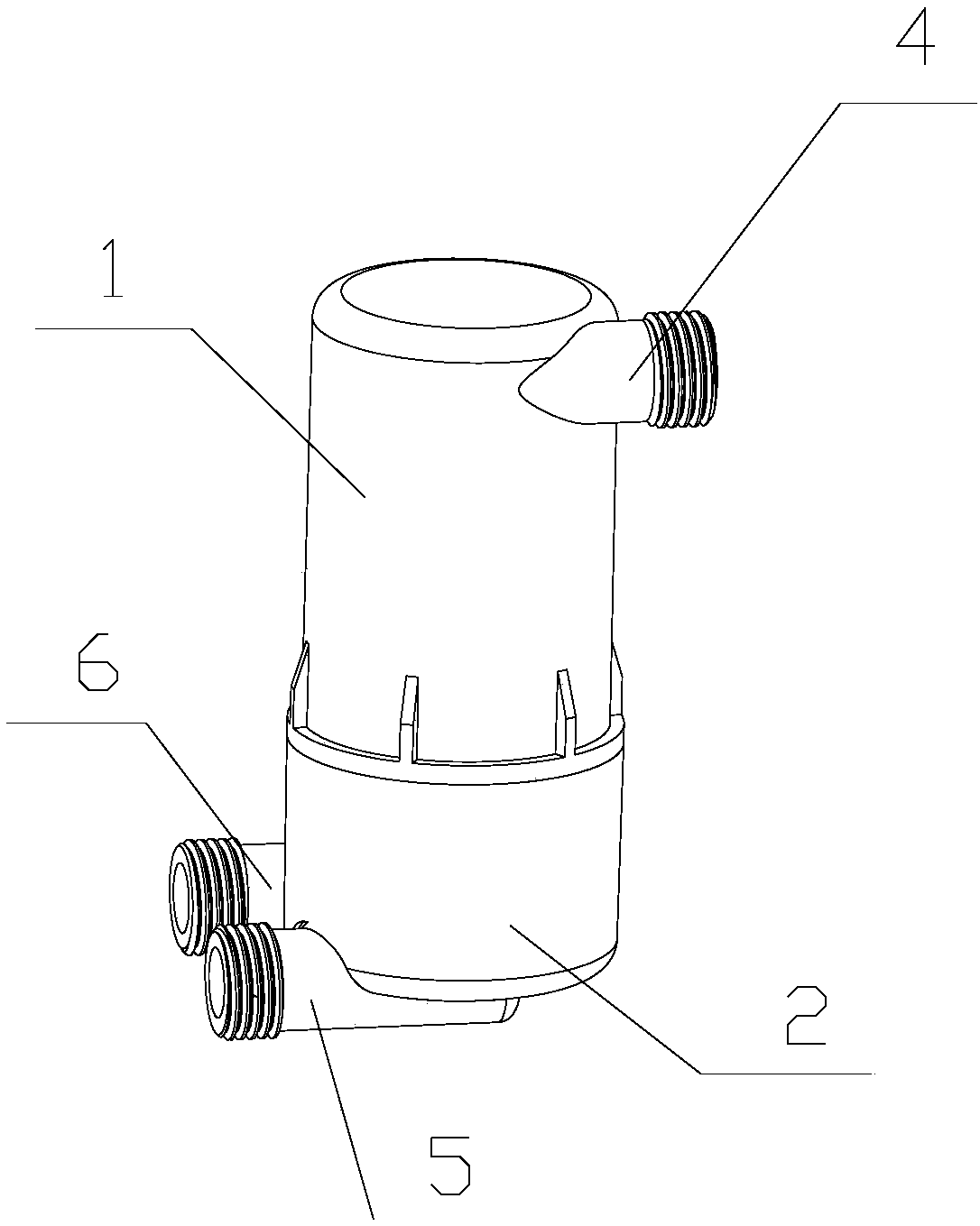

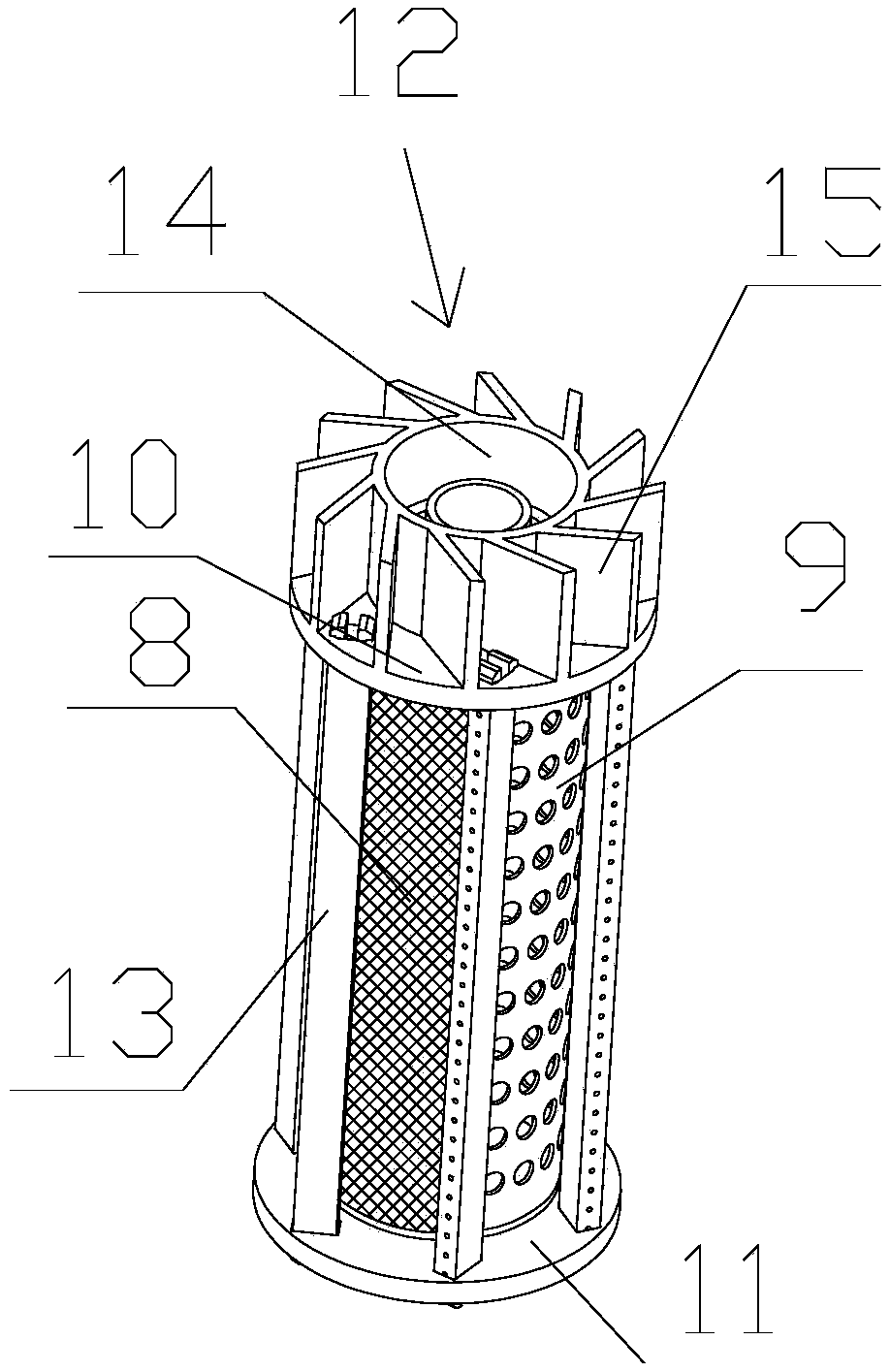

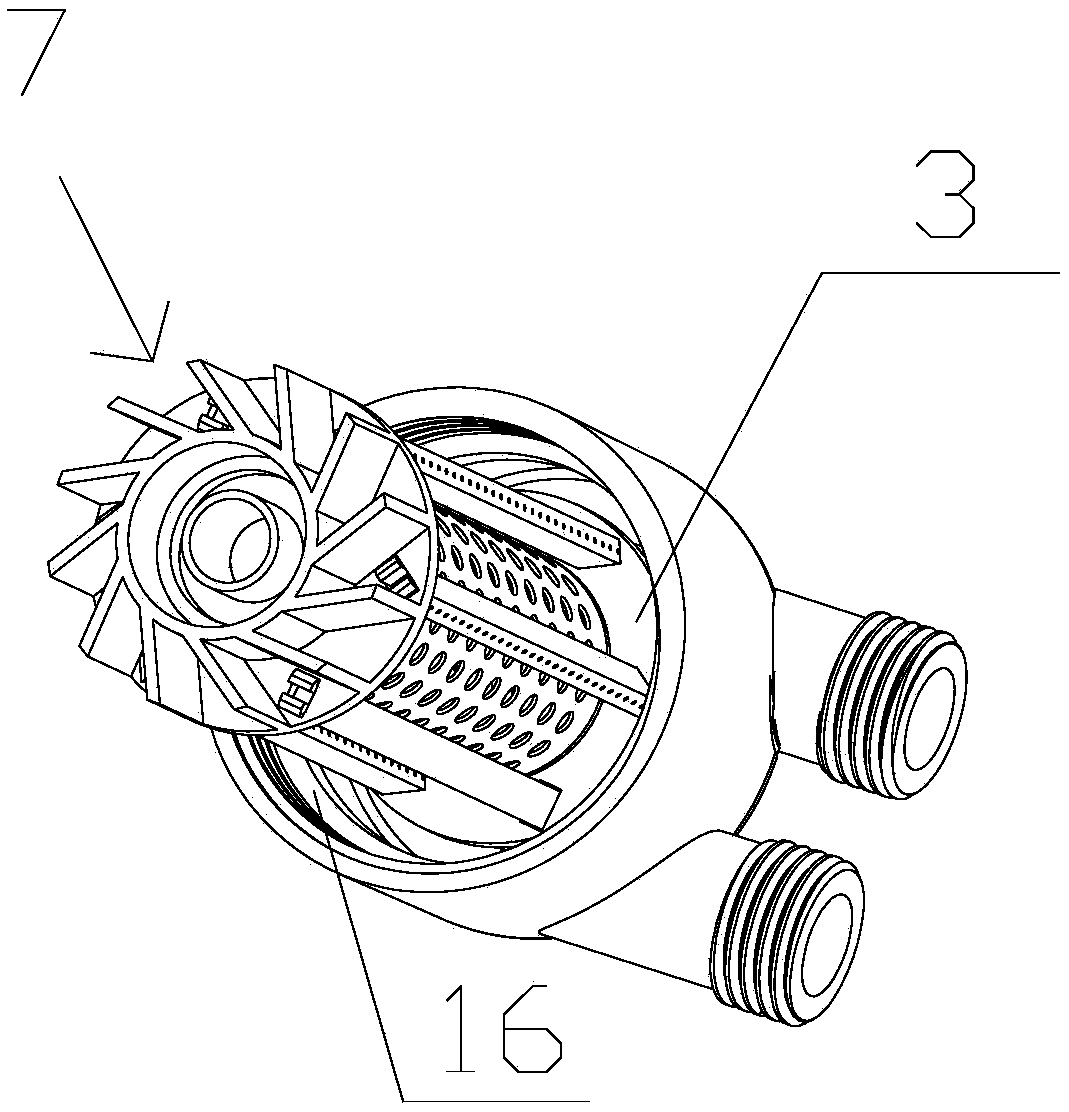

[0033] As shown in the figure, a self-cleaning pre-filter includes an upper cylinder 1 and a lower cylinder 2 that cooperate with each other. A closed chamber 3 is formed between the upper cylinder 1 and the lower cylinder 2. The upper cylinder The upper part of 1 is provided with a water inlet 4 communicating with the chamber 3, and a filter device 7 is provided in the chamber 3, and the chamber 3 is divided into a water purification chamber and a sewage chamber, the water purification chamber is connected to the water purification port 5, and the sewage chamber is connected to The sewage outlet 6 and the filter device 7 are also provided with a cleaning device, which can rotate around the filter device 7 and clean the filter device 7 .

[0034] The water flow enters from the water inlet 4 and enters the chamber 3 between the upper cylinder body 1 and the lower cylinder body 2. The water flow flowing into the chamber 3 is filtered by the filter device 7, and the clean water is...

Embodiment 2

[0045]Especially with the development of smart homes, more and more families start to use smart toilets. A major feature of smart toilets is the body cleaning function. In many buildings at present, most of the toilets are connected to tap water. The urban tap water pipes are aging or the tap water storage tanks on high-rise buildings cannot be cleaned frequently, so that the tap water contains a lot of rust and mud. There are many large particles of organic matter such as sand. These large particles will cause the nozzle of the smart toilet to be blocked. Due to the entry of large particles of organic matter into the water inlet solenoid valve, the solenoid valve will not close firmly and water leakage will occur. The self-cleaning filter in the present invention can also be used in an intelligent toilet to further filter reclaimed water to remove impurities, and the clean water after removal of impurities is used to flush the body, and the water containing impurities is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com