Material mixing device for producing glyphosate powder

A mixing device and glyphosate technology are applied in the field of mixing devices, which can solve the problems of low mixing quality and achieve the effects of high mixing quality, avoiding low mixing quality and uniform material mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

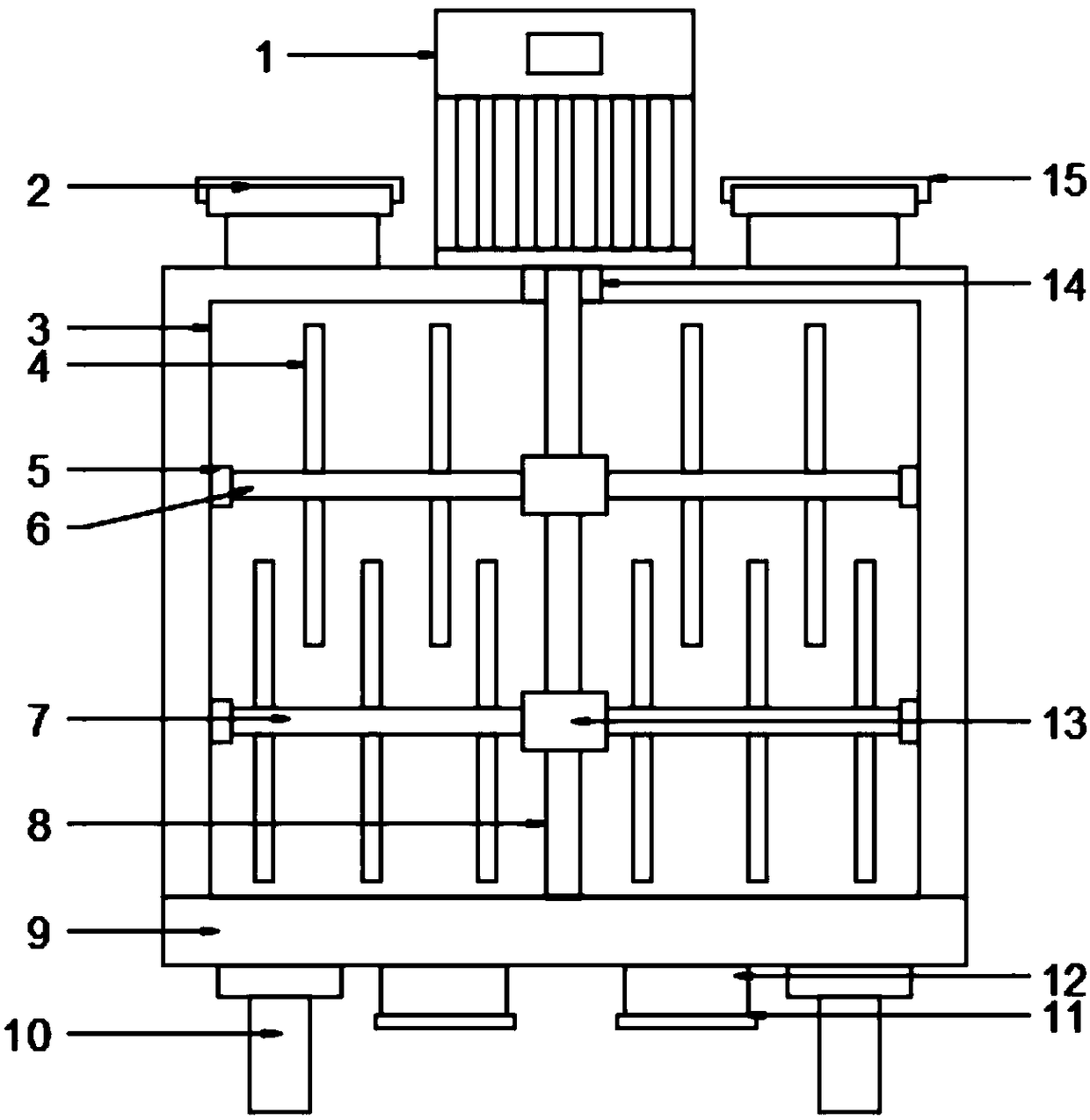

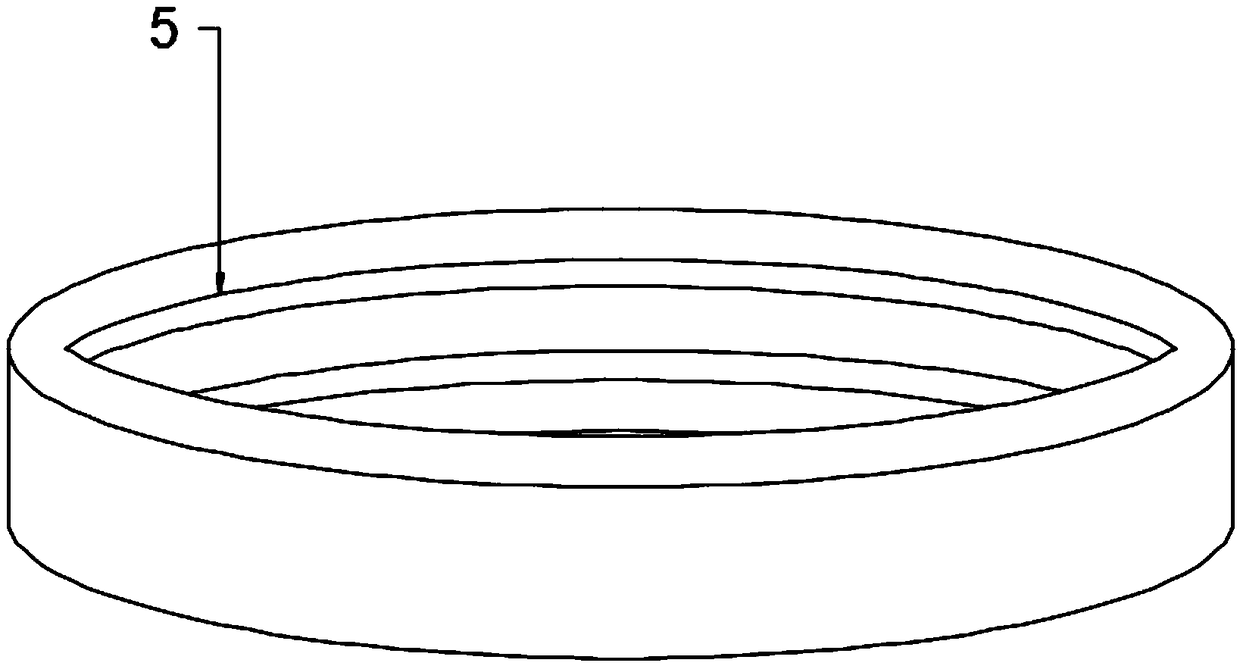

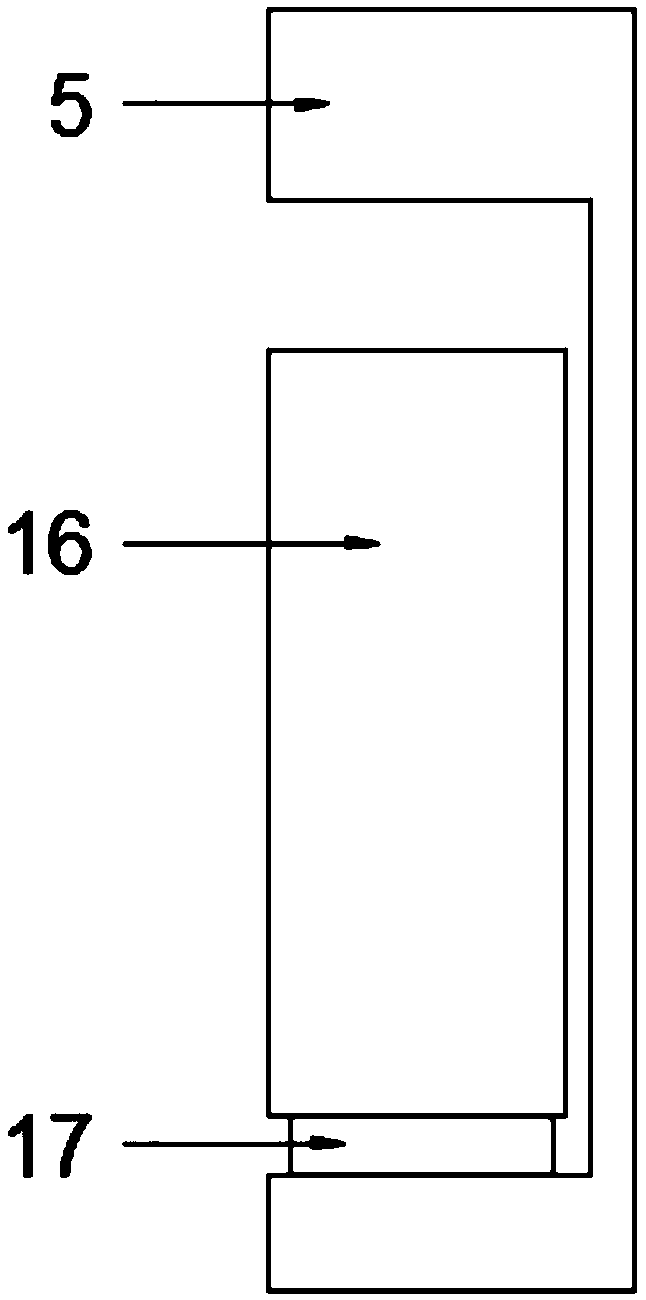

[0024] see Figure 1-4 , a mixing device for the production of glyphosate powder, comprising a mixing box 3 and a rotating stirring frame 7, the inside of the mixing box 3 is provided with two limiting rings 5 arranged in parallel, and the inside of the limiting ring 5 The side is provided with a chute, the bottom of the chute is provided with a rack 17, and the rack 17 is arranged in a ring shape, and the rotation stirring frame 7 is provided with four. There are stirring rods 4 distributed in an array, and the outer end of the rotation shaft 6 is inserted in the limit ring 5, and the rotation shaft 6 is fixed with a gear 16 in the limit ring 5, and the gear 16 and the rack 17 are meshed.

[0025] The upper end of the mixing box 3 is provided with two symmetrically arranged feeding pipes 2, the upper cover of the feeding pipe 2 is provided with a second sealing cover 15, the lower end of the mixing box 3 is fixed on the bottom plate 9, and the lower end of the bottom plate ...

Embodiment 2

[0029] see Figure 1-3 with Figure 5 , a mixing device for the production of glyphosate powder, comprising a mixing box 3 and a rotating stirring frame 7, the inside of the mixing box 3 is provided with two limiting rings 5 arranged in parallel, and the inside of the limiting ring 5 The side is provided with a chute, the bottom of the chute is provided with a rack 17, and the rack 17 is arranged in a ring shape, and the rotation stirring frame 7 is provided with four. There are stirring rods 4 distributed in an array, and the outer end of the rotation shaft 6 is inserted in the limit ring 5, and the rotation shaft 6 is fixed with a gear 16 in the limit ring 5, and the gear 16 and the rack 17 are meshed.

[0030] The upper end of the mixing box 3 is provided with two symmetrically arranged feeding pipes 2, the upper cover of the feeding pipe 2 is provided with a second sealing cover 15, the lower end of the mixing box 3 is fixed on the bottom plate 9, and the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com