Adjustable velocity-reducing chamber type oil chip separator

A kind of oil debris separation and adjustable technology, applied in the direction of centrifuges and centrifuges with rotating drums, can solve the problem that metal scraps and cooling oil cannot be guaranteed, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

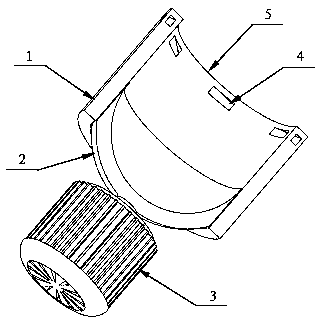

[0013] 1. The structure of the deceleration chamber adjustable oil debris separator

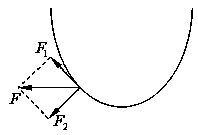

[0014] Such as figure 1 As shown, the deceleration chamber adjustable oil debris separator consists of a casing, a hollow cylinder (1), a rotating pot (2) and a motor (3). The hollow cylinder (1) is sleeved on the outside of the rotating pot (2), and can slide up and down along the common axis of symmetry and be locked. The two form the rotating body of the separator and are installed inside the shell. The motor (3) is installed below the shell, and the motor (3) is connected with the rotating shaft of the rotary pot (2). The rotating pot (2) and the hollow cylinder (1) form a smooth curved surface, so as to avoid damage to the inner wall of the hollow cylinder (1) caused by metal shavings moving at high speed. The upper end of the hollow cylinder (1) is provided with evenly distributed oil outlets (4), and the cylindrical cavity below the oil outlet (4) and above the rotating pot (2) is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com