Dry vertical grading impeller

A classification impeller, vertical technology, applied in solid separation, chemical instruments and methods, separation of solids from solids by air flow, etc. Achieve the effect of improving classification accuracy, reducing classification particle size and improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

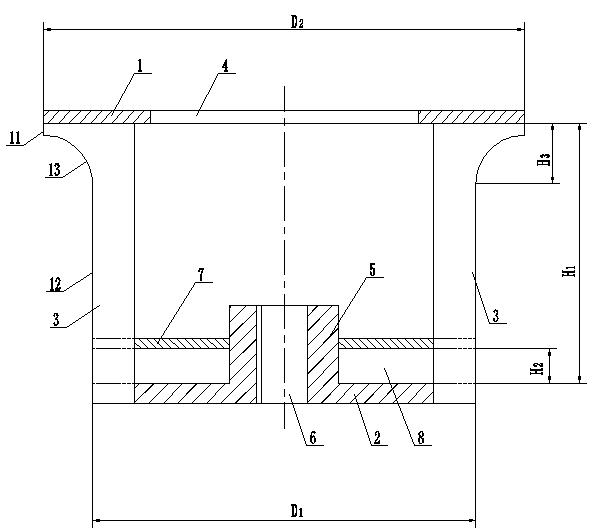

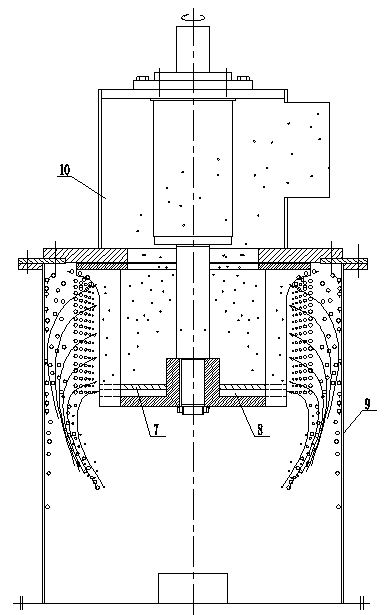

[0015] like figure 1 As shown, the dry vertical grading impeller includes a top plate 1, a chassis 2, and a plurality of blades 3 connected to the top plate 1 and the bottom plate 2 and evenly distributed around the ring. The center of the top plate 1 is provided with an impeller shaft penetration hole 4, The central portion of the top surface of the chassis 2 protrudes upwards to form a boss 5, and the boss 5 is provided with an impeller shaft mounting hole 6. The boss 5 is fixedly connected with a spacer 7 spaced apart from the chassis 2, the edge of the spacer 7 is fixedly connected with the blade 3, and the spacer 7 is arranged in parallel with the chassis 2, so that there is a gap between the chassis and the spacer. A buffer space 8 that communicates with the outside of the impeller and does not communicate with the inside of the impeller through the gap between adjacent blades is formed between them. The outer side of described blade 3 is made of the short straight sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com