Aluminum profile continuous extrusion interrupting method and device capable of achieving automatic weld joint finding

An aluminum profile, automatic technology, applied in the field of material processing, can solve the problems of incomplete thickness control, difficult sawing near the weld, and accumulated errors, etc., to achieve excellent craftsmanship, realize full automation, and reduce labor and production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

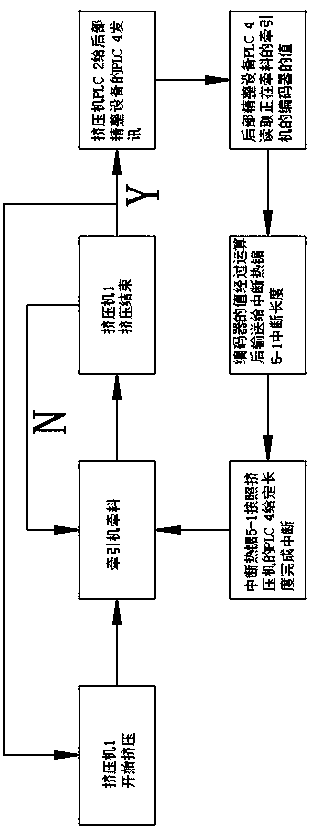

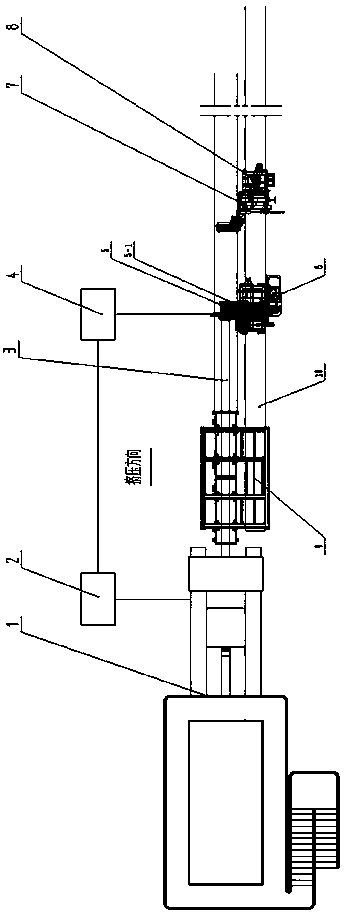

[0021] Such as figure 1 As shown, a continuous extrusion interruption device for aluminum profiles that automatically finds welds includes at least an extruder 1, and is characterized in that the discharge end of the extruder 1 is provided with a rail 10 along the extrusion direction. 10 is connected with a tractor slidingly, an interrupting saw 5-1 is fixedly connected to the tractor, and a rear finishing equipment PLC4 is fixed and electrically connected to the tractor. The tractor is driven on the track through the rear finishing equipment PLC4 10 slides up, the extruder 1 is electrically connected to the extruder PLC2, and the extruder PLC2 is electrically connected to the rear finishing equipment PLC4.

[0022] In the extrusion production process, the tractor is responsible for pulling the extruded aluminum profile 3. When each aluminum ingot is extruded, the extruder PLC2 sends a message to the rear finishing equipment PLC4, and the rear finishing is at this time The equipm...

Embodiment 2

[0024] Such as figure 1 As shown, it is based on Example 1: The tractor is composed of a main tractor 7 and an auxiliary tractor 5. The auxiliary tractor 5 is located between the extruder 1 and the main tractor 7, and the auxiliary tractor 5 The rear finishing equipment PLC4 is connected to the power.

[0025] An encoder two 8 is fixedly connected to the main tractor 7, and the encoder two 8 is connected to the rear finishing equipment PLC4 and the extruder PLC2 with electrical signals.

[0026] The encoder two 8 is used to monitor the position of the main tractor 7 in real time and take the die end surface of the discharge end of the extruder 1 as the zero point.

[0027] The auxiliary tractor 5 is also fixedly connected with an interrupting saw 5-1, and the auxiliary tractor 5 and the interrupting saw 5-1 are fixedly connected with an encoder-6, the encoder-6 and the rear part The finishing equipment PLC4 and the extruder PLC2 are connected with electrical signals.

[0028] The enc...

Embodiment 3

[0032] On the basis of embodiment 2: the track 10 between the auxiliary tractor 5 and the extruder 1 is provided with a quenching device 9, where the track 10 passes through the quenching device 9. The quenching device belongs to the prior art. The structure belongs to the well-known technology of those skilled in the art, and will not be specifically described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com