A method and device for reducing the temperature drop of molten iron

A technology of molten iron and water temperature, which is applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of affecting the life of tank linings and increasing costs, and achieve the effect of reducing methods, reducing the temperature drop of molten iron, and reducing the temperature drop of molten iron.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

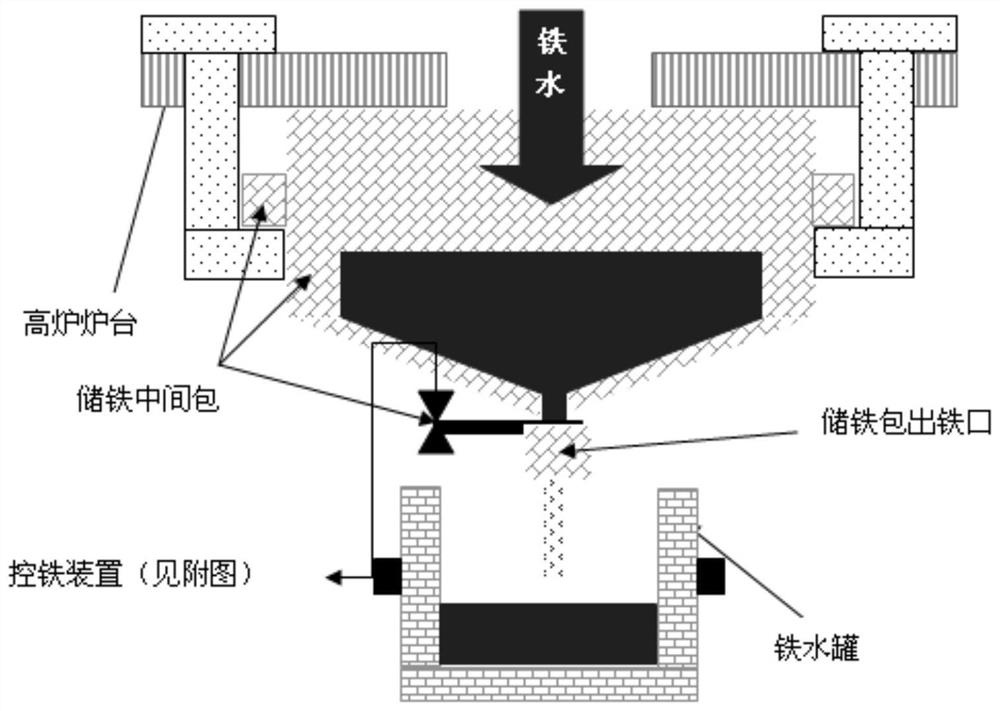

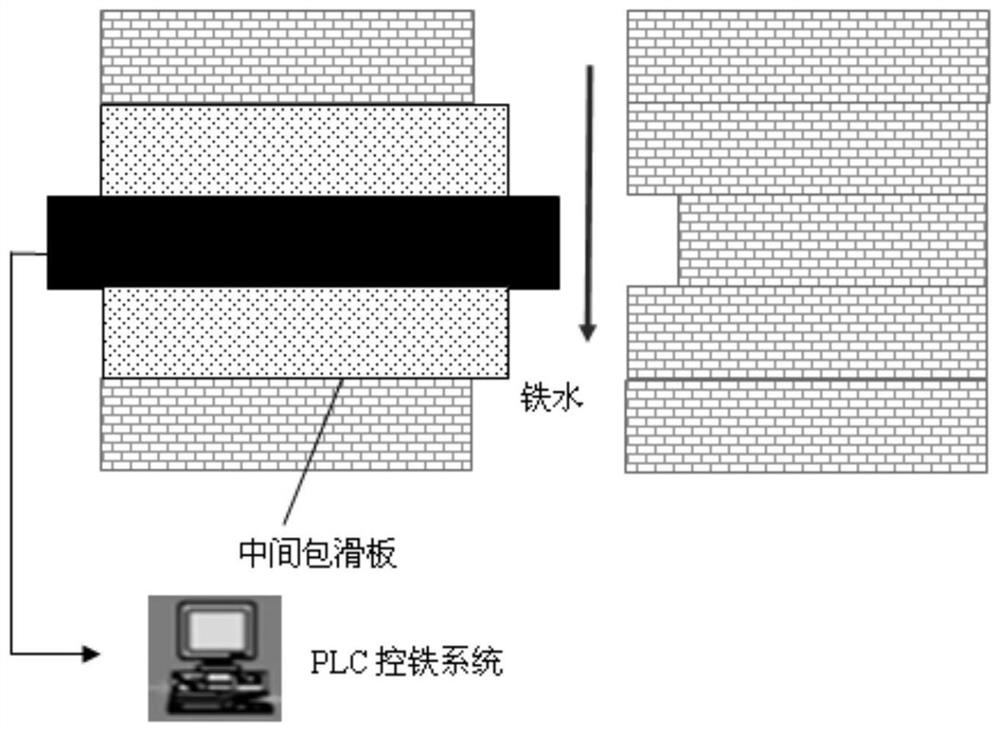

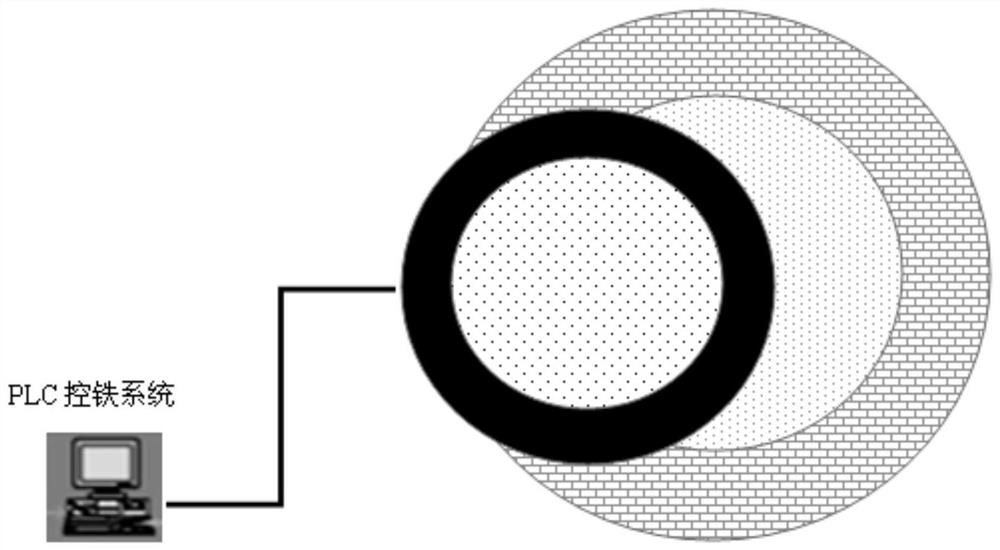

[0053] This embodiment provides a device for reducing the temperature drop of molten iron, the structural diagram is as follows figure 1 shown, including:

[0054] Blast furnace tapping equipment;

[0055] The iron storage tundish fixedly arranged under the taphole of the blast furnace tapping equipment, the fixing method of the iron storage tundish is as follows:

[0056] The two ends of the hearth below the blast furnace tapping equipment are provided with through holes that penetrate up and down. A hook is placed inside the through hole, and the upper end of the hook is fixed on the upper surface of the hearth. The upper space of the iron storage tundish is shielded to a certain extent, so that the iron storage tundish exposes the inlet to ensure that the molten iron from the blast furnace can enter the iron storage tundish.

[0057] The outlet of the taphole of the blast furnace tapping equipment communicates with the inlet of the iron storage tundish through a tapping c...

Embodiment 2

[0062] Adopt the device described in embodiment 1 to carry out tapping:

[0063] The molten iron in the blast furnace tapping equipment flows into the iron storage tundish through the tapping channel for storage. The distance between the lower edge of the iron storage tundish taphole is 1m higher than the upper edge of the molten iron tank. The molten iron flow rate of the blast furnace tapping equipment taphole The tapping time is 2.5T / min, and the tapping time is 100min. After the blast furnace tapping is completed and the molten iron tank is in place, the flow rate of the molten iron in the iron storage tundish flowing into the molten iron tank is controlled by the iron control device of the iron storage tundish to 3.5T / min , the time for all to flow into the molten iron tank is 70 minutes.

[0064] In the above iron tapping process, when the iron was tapped for 30 minutes, the temperature of the molten iron at the small well of the iron ditch was tested to be 1450°C. After...

Embodiment 3

[0066] Adopt the device described in embodiment 1 to carry out tapping:

[0067] The molten iron in the blast furnace tapping equipment flows into the iron storage tundish through the tapping channel for storage. The distance between the lower edge of the iron storage tundish taphole is 1m higher than the upper edge of the molten iron tank. The molten iron flow rate of the blast furnace tapping equipment taphole The tapping time is 2.5T / min, and the tapping time is 100min. After the blast furnace tapping is completed and the molten iron tank is in place, the flow rate of the molten iron in the iron storage tundish flowing into the molten iron tank is controlled by the iron control device of the iron storage tundish at 5T / min. The time for all to flow into the molten iron tank is 50 minutes.

[0068] In the above iron tapping process, when the iron was tapped for 30 minutes, the temperature of the molten iron in the small well of the iron ditch was tested to be 1450°C. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com