Method and device for checking quantity and purity in pressure swing adsorption plants

A pressure swing adsorption and equipment technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increased possibility of failure, reduced capacity, and pressure drop, and achieves continuously variable load adaptation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

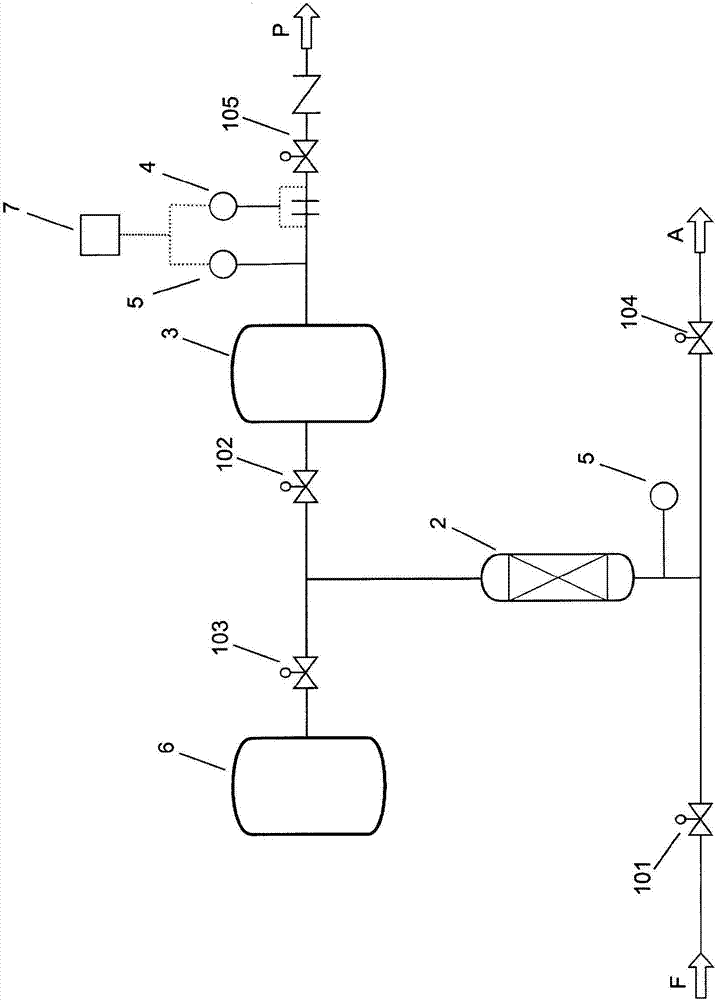

[0091] figure 1 is a schematic diagram of a single adsorber apparatus suitable for carrying out the method according to the invention.

[0092] The pressure swing adsorption equipment 1 includes an adsorber 2, a product buffer 3, a pressure buffer 6, a quantity measuring device 4, two pressure measuring devices 5, a gas supply valve 101, a product valve 102, a discharge valve 103, and an exhaust valve 104 and purge valve 105.

[0093] The quantity measuring device 4 allows determining the quantity of product gas P withdrawn from the product buffer 3 . The pressure measuring device 5 allows the pressure in the adsorber 2 and in the product buffer 3 to be determined.

[0094] In the present case, the method has a working cycle comprising a pressure build-up phase, a production phase, a discharge phase, a regeneration phase and a charging phase, wherein an idle phase is arranged between two working cycles, that is to say Before the pressure build-up phase and after the chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com