Rotating disc mechanism of rotating disc type internal polishing machine

A turntable mechanism and turntable technology, which is applied in the field of polishing machines, can solve the problems of reducing polishing efficiency, time-consuming and laborious, and low polishing efficiency, and achieve the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

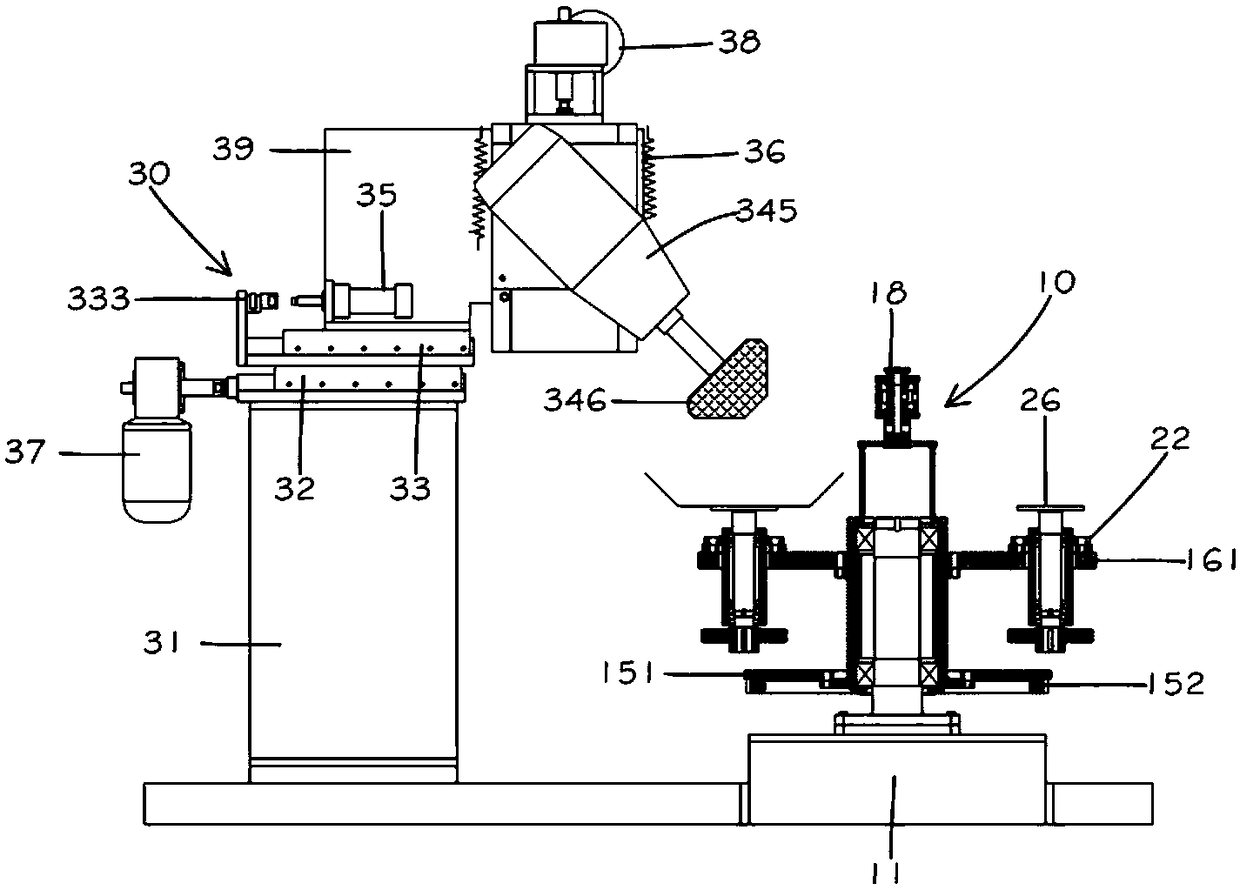

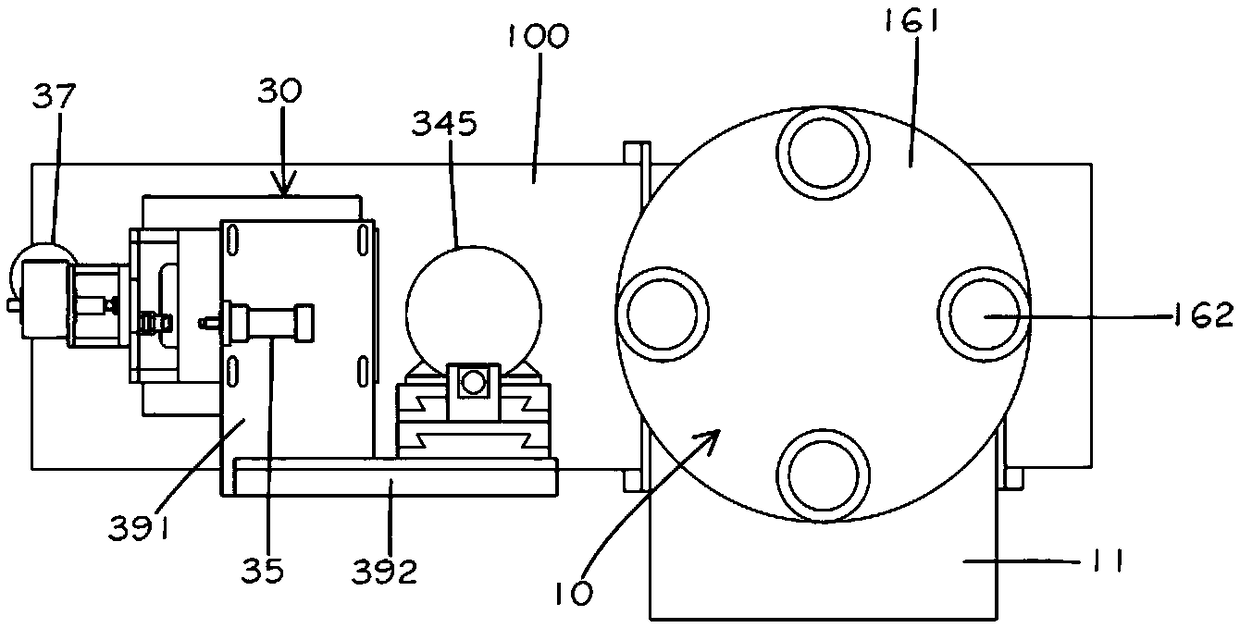

[0029] Such as Figure 1 to Figure 18 The turntable mechanism of this turntable type internal throwing machine of the present invention as shown, it comprises a base 100, and the turntable mechanism 10, inverted throwing inner bottom mechanism 30 and workpiece rotation mechanism 20 are installed on the base 100, and workpiece rotation mechanism 20 includes active The gear assembly 21 and the driven gear assembly 22 , the driving gear assembly 21 is installed on the base, and the driven gear assembly 22 is installed on the turntable mechanism 10 .

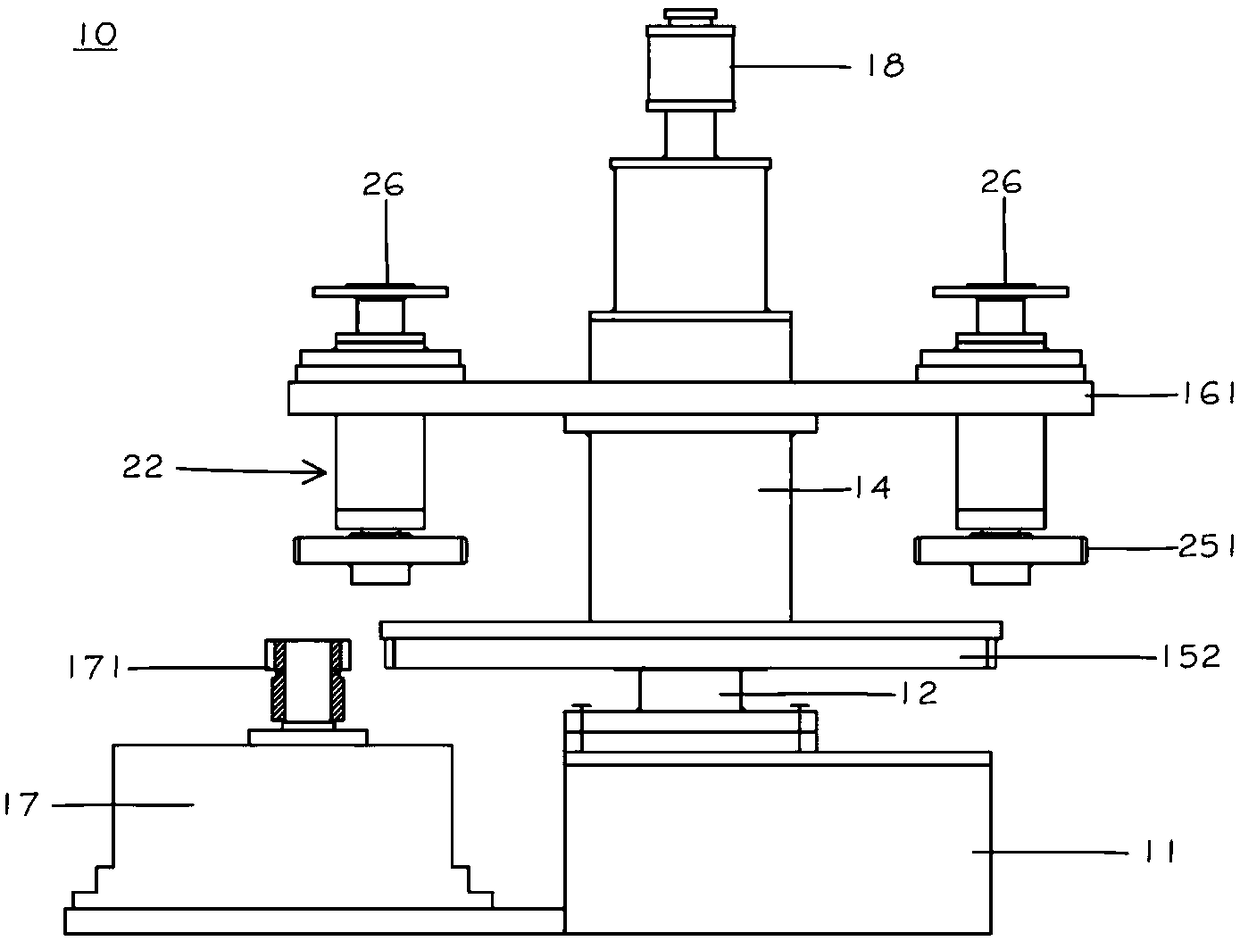

[0030] The turntable mechanism 10 includes a mounting seat 11, on which a turntable shaft 12 is fixed, the turntable shaft 12 is provided with a bearing 13, the outer end of the bearing 13 is provided with a turntable positioning sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com