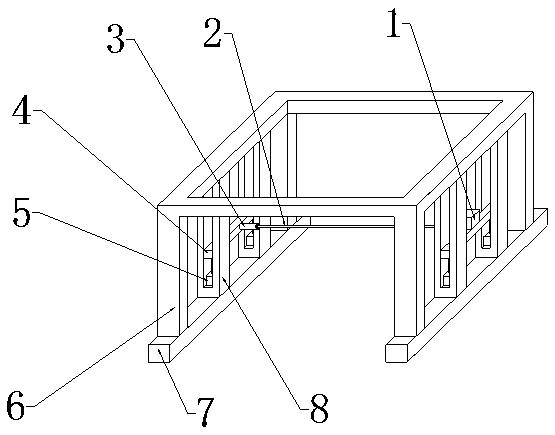

Steel wire cleaning device of masonry block slitting machine

A technology of cleaning device and slitting machine, which is applied to ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of affecting production efficiency, affecting product appearance and quality, and uneven unevenness of blanks, so as to increase the workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

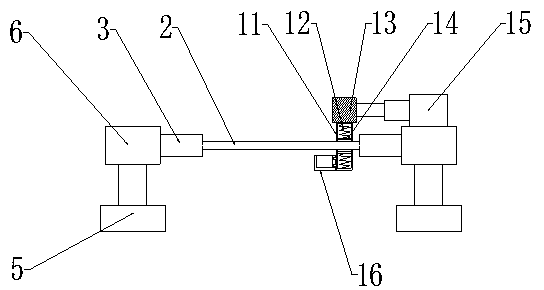

Examples

specific Embodiment approach

[0020] Specific implementation: when in use, the user first opens the electric cylinder one 5, the electric cylinder one 5 works to make the moving plate 4 move upward, the moving plate 4 moves upward to drive the fixed cylinder 3 to move upward, and the fixed cylinder 3 moves upward to drive the steel wire 2 to move upward , when the steel wire 2 moves up to the set position, close the electric cylinder one 5, and then the user passes the concrete block to be cut through the steel wire 2, thus realizing the function of horizontally cutting the block. When the steel wire 2 is used for a section After time, the user turns on the electric cylinder 2 15, the electric cylinder 2 15 works to push the fixed block 13 to move to the left, the fixed block 13 moves to the left to drive the hollow cylinder 11 to move to the left, and the hollow cylinder 11 moves to the left to drive the spring 12 and ash collection The groove plate 16 moves to the left, and the spring 12 moves to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com