Environment-friendly panel

A board and environmental protection technology, applied in the field of board structure, can solve the problems of not being able to purify the air, not being able to reduce dust mites, and not having a long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

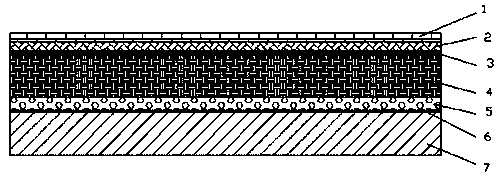

[0020] Such as figure 1 As shown, the present invention provides an environmentally friendly board, which includes a moisture-proof layer 1, a glass fiber resin layer 2, a high-fiber resin powder layer 3, a board layer 4, a bamboo charcoal powder layer 5, and a hot pressing plate layer 7. The moisture-proof layer 1, The glass fiber resin layer 2, the high-fiber resin powder layer 3, the sheet layer 4, the bamboo charcoal powder layer 5, and the hot pressing plate layer 7 are arranged in order in the height direction. The moisture-proof layer 1 has a thickness of 2 mm, and the glass fiber resin layer 2 has a thickness of 2mm, the high-fiber resin powder layer 3 has a thickness of 1mm, the plate layer 4 has a thickness of 10mm, the bamboo charcoal powder layer 5 has a thickness of 3mm, and the hot press plate layer 7 has a thickness of 10mm.

[0021] The moisture-proof layer 1 is a plastic film. The plastic film has good moisture-proof effect. It can effectively protect the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com