Intelligent box body stacking machine

A technology of body palletizer and smart box, applied in the field of transport and storage machinery and equipment, which can solve the problems of inability to perform code division, caching, and inability to solve bottom-up palletizing and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

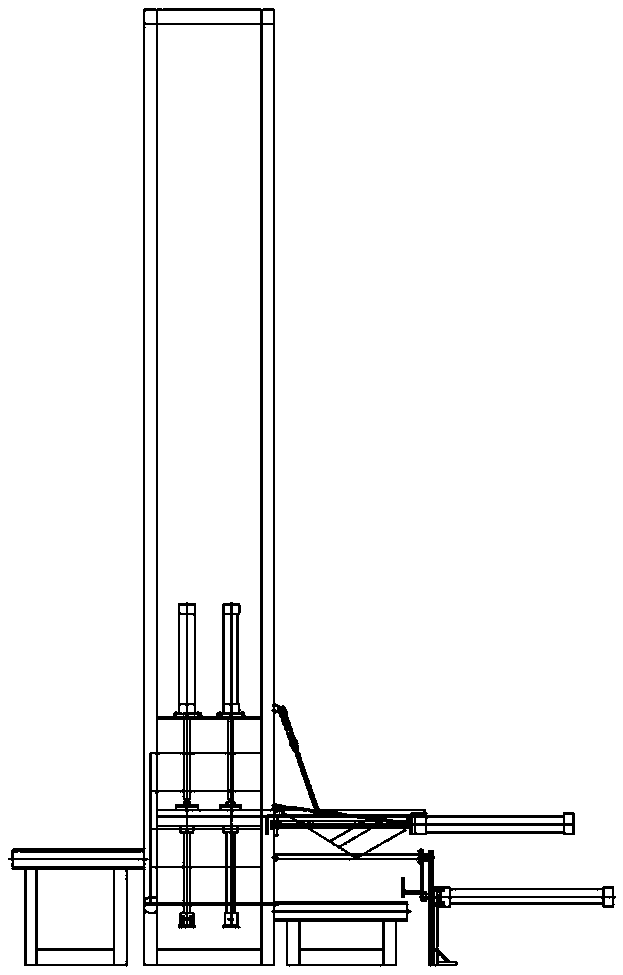

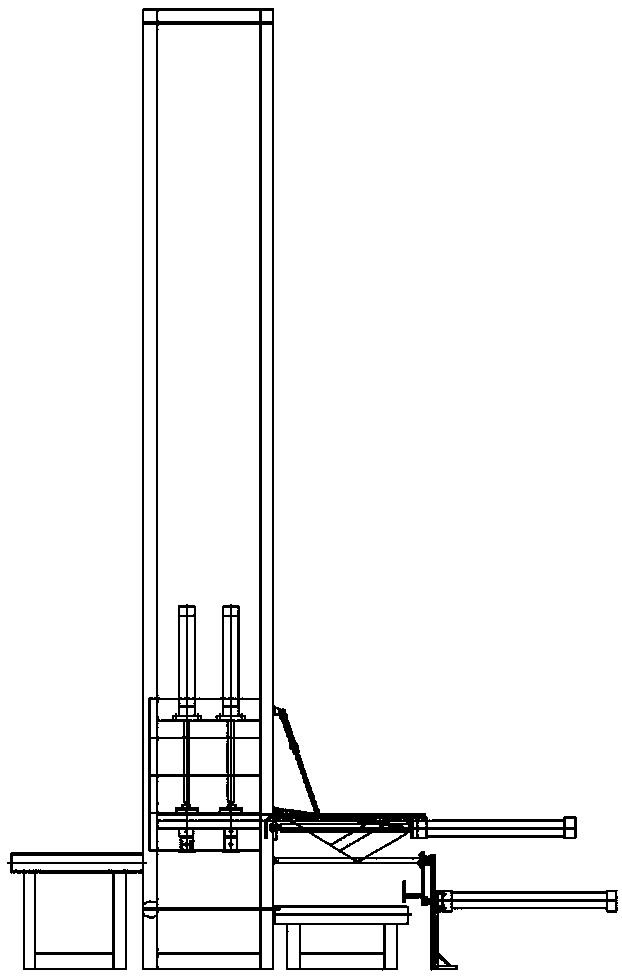

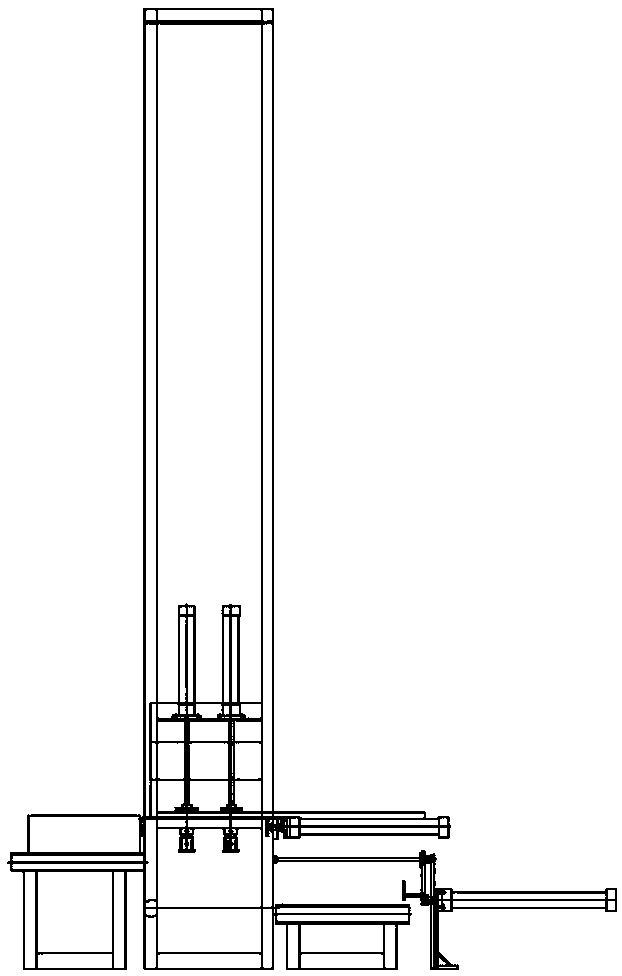

[0026] This embodiment is a box palletizer with an intelligent control system for shoebox coding, stacking, buffering, and chopping (the intelligent control system includes hardware such as barcode recognition devices, sensing devices, and PLCs, all using prior art, without further details), its basic structure is as figure 1 , 2 , 3, the vertical extension frame body 1 with multiple columns (15 columns in the present embodiment) stacking stand is divided into 15 buffer areas, and its two sides are respectively arranged as the horizontal input of the input transmission device and the output transmission device Conveyor belt 7 and output conveyor belt 3. The lower part of each palletizing unit of the frame body 1 is fixed with a placement plate 12 whose upper surface is flush with the upper surface of the input conveyor belt 7 . The frame body 1 is respectively installed with a lifting mechanism 2 that can be lifted between the low position and the high position above the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com