Turn-over equipment

A technology of equipment and racks, which is applied in the field of flipping equipment, can solve the problems of flipping operators such as exposure to sunlight, low efficiency, and high light intensity, and achieve the effects of low cost, high efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

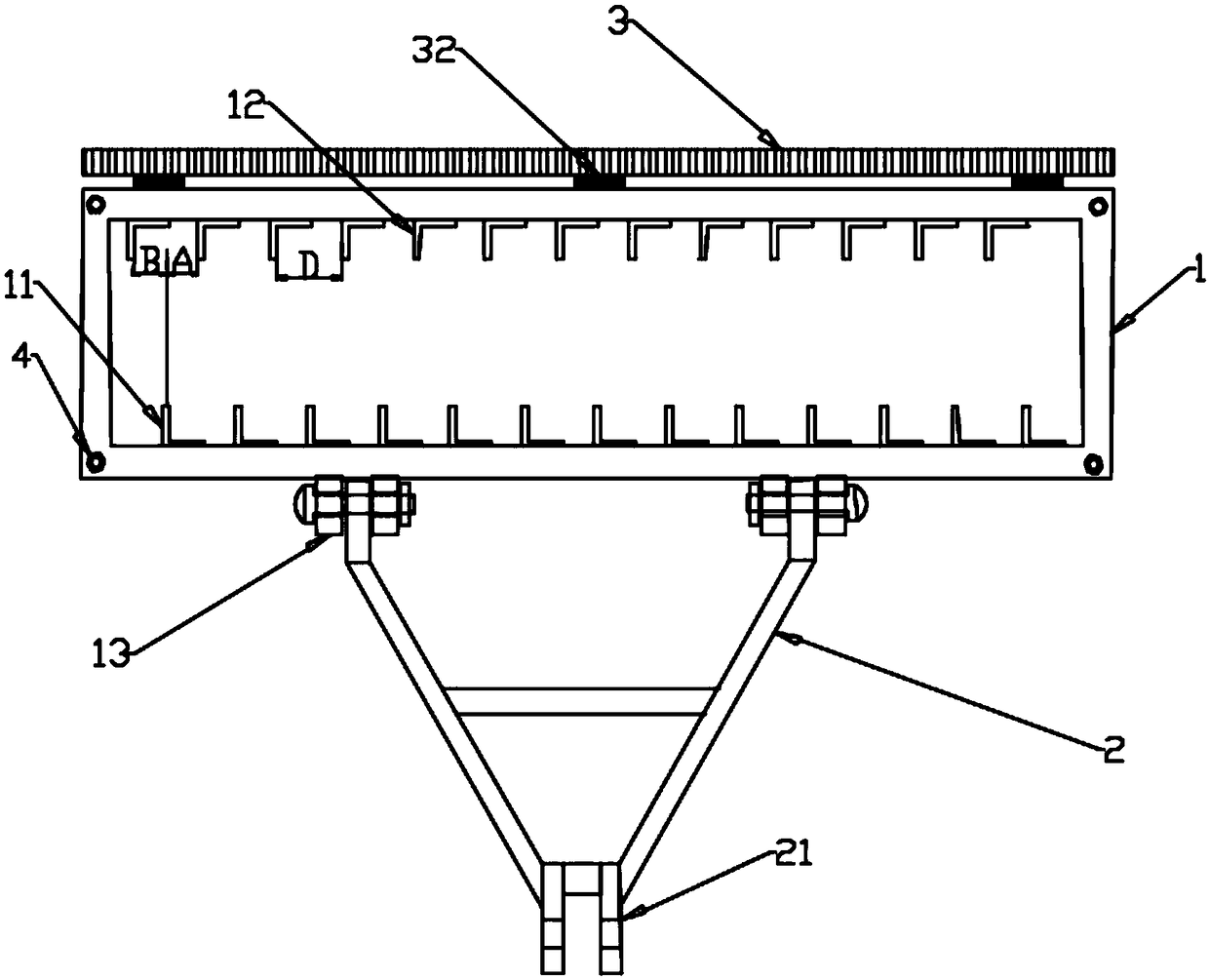

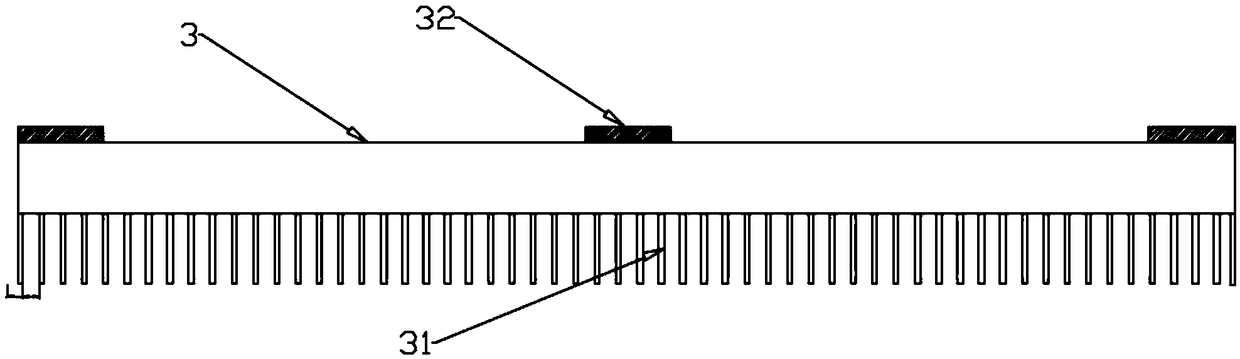

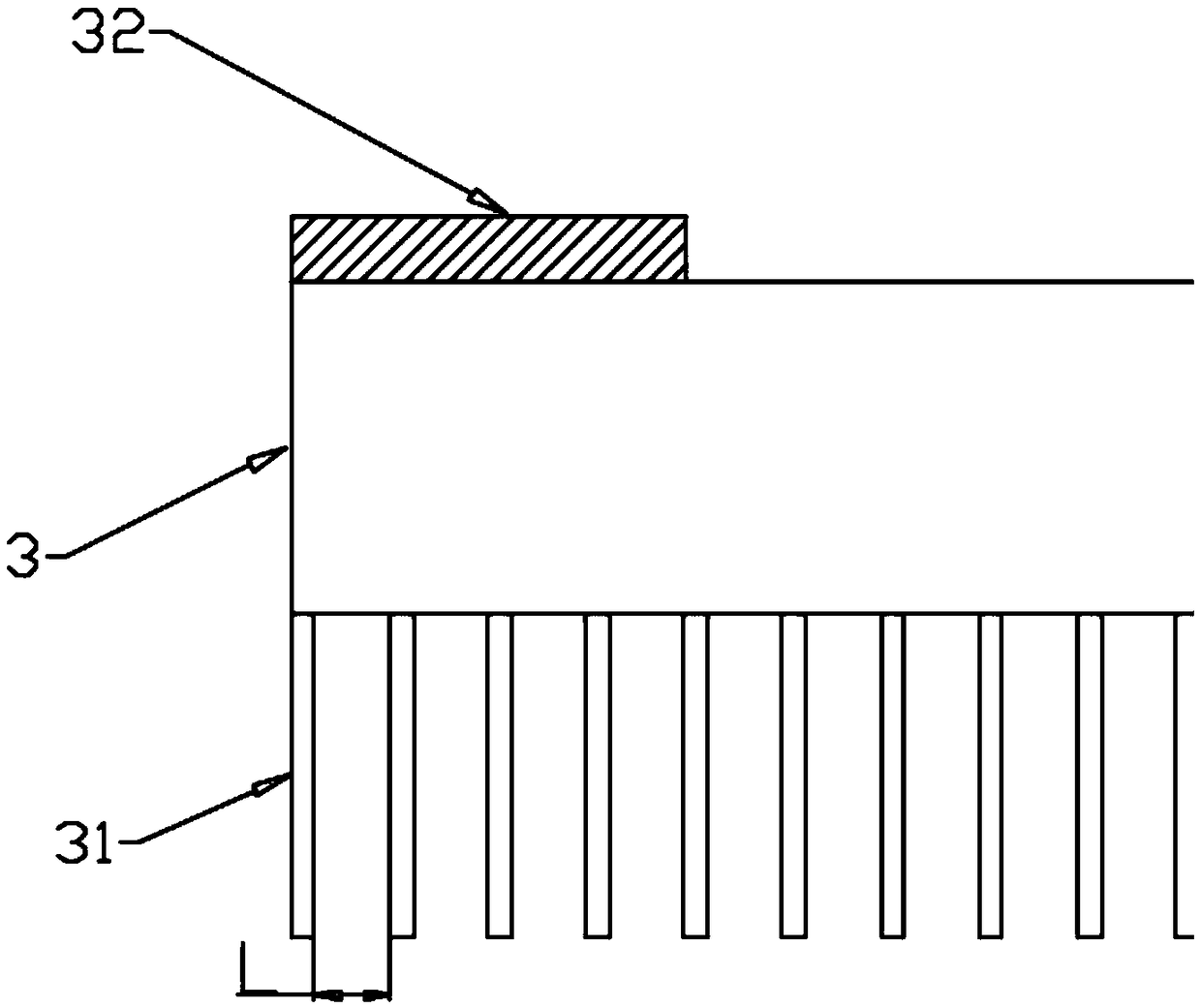

[0022] Such as figure 1 Shown: a kind of flipping equipment, including a frame 1 and a hanger 2, the side of the frame 1 is provided with two rack ear plates 13, the rack ear plate 13 is detachably connected to one end of the hanger 2, and the hanger The other end of 2 is provided with the hanger lug 21 that is used to connect agricultural machinery, and the front end inner edge of frame 1 is provided with the front scraper 11 of some equidistant arrangement, and the rear end inner edge of frame 1 is provided with some equidistant arrangement. The distance between the adjacent front scrapers 11 and the distance between the adjacent rear scrapers 12 is equal, the front scrapers 11 and the rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com