Silencing steam trap for steam pipe

A sound-absorbing steam trap and steam trap technology, applied in steam traps, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as large noise pollution, loud noise, and human injury, so as to improve safety and reduce noise Pollution and the effect of reducing occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

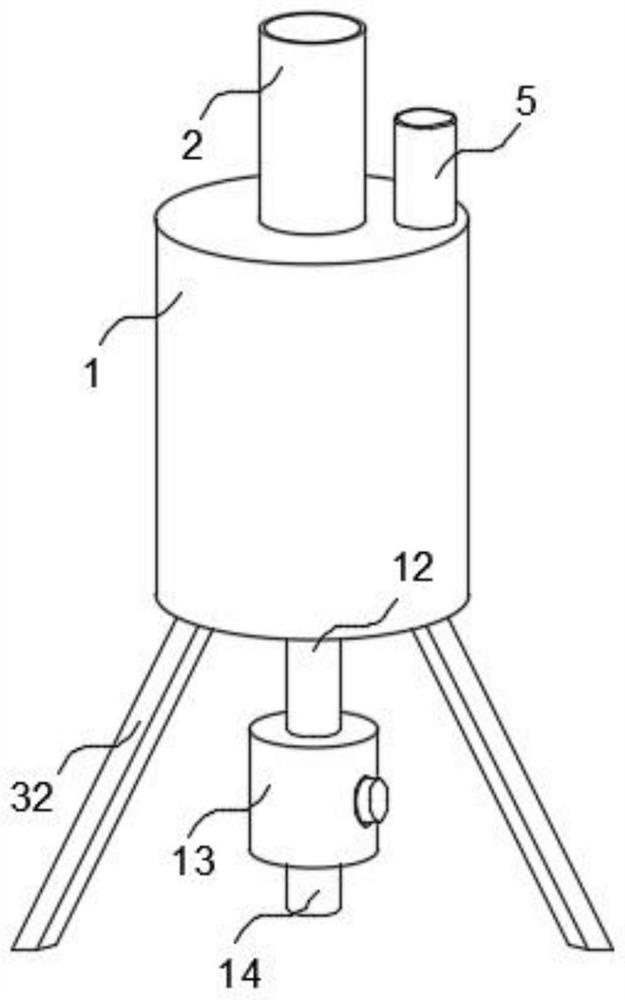

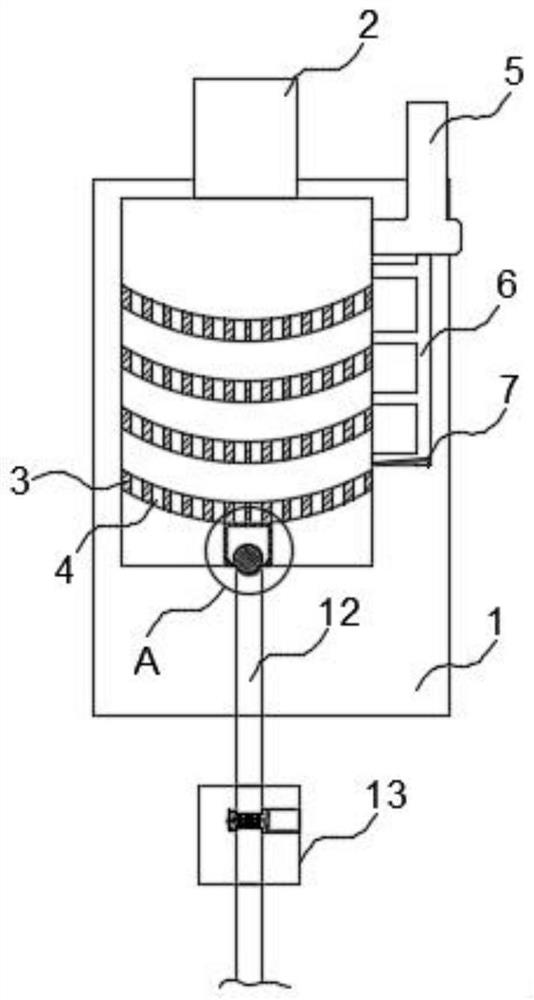

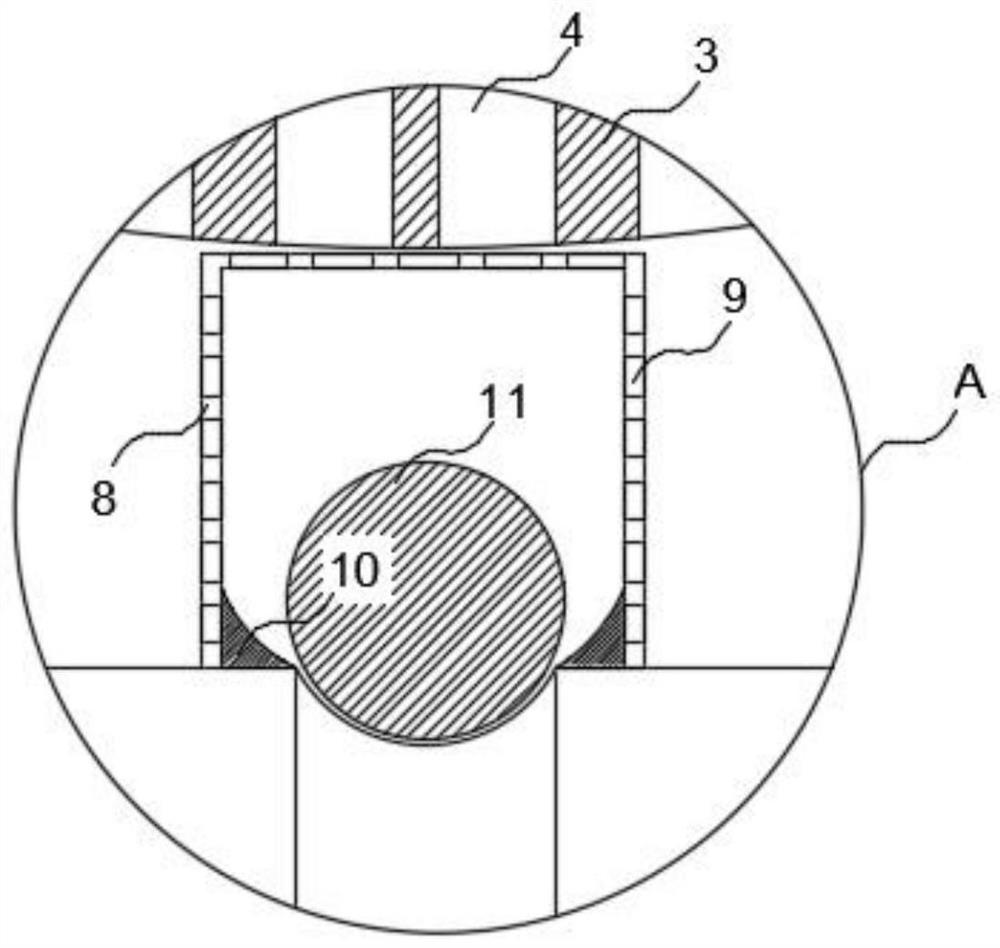

[0029] Such as Figure 1-8 As shown, the present invention proposes a sound-absorbing steam trap for steam pipes, including a steam trap main body 1, an air inlet pipe 2 is provided on the outer surface of the upper end of the steam trap main body 1 near the middle position, and the interior of the steam trap main body 1 is equidistant from There are several fixed plates 3 fixedly connected, and the fixed plates 3 are in an arc-shaped structure, which are used to guide the water generated by the gas, and can introduce water into the bottom of the steam trap main body 1 for collection. The outer surfaces of the upper ends of the fixed plates 3 are equidistant from each other. Several through holes 4 are provided, and an exhaust pipe 5 is provided on one side of the main body of the steam trap near the upper end. The air hole is used to guide the gas into the exhaust pipe 5 for discharge, and it communicates with the inside of the steam trap main body 1. The inside of the air gu...

Embodiment 2

[0033] Such as Figure 1-8 As shown, the first drain pipe 12 penetrates to the inside of the steam trap main body 1 and extends to the outside. The outer surface of the lower end of the first drain pipe 12 is fixedly connected with an attachment 13, and the interior of the attachment 13 A second drainpipe 14 is provided near the middle position, and the second drainpipe 14 and the first drainpipe 12 communicate with each other. The right side outer surface of the add-on part 13 is provided with a mounting groove 15 near the middle position, and the installation The groove 15 communicates with the second drain pipe 14. A rotating block 16 is arranged inside the installation groove 15 for fixing the fixed block 19. The left outer surface of the rotating block 16 is fixedly connected with a connector 17. The outer surface of the left side of the connector 17 is provided with a fixed block 19, and the inner middle position of the fixed block 19 is provided with a threaded groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com