Biomass porous concrete sound absorption material and preparation method thereof

A technology for porous concrete and biomass materials, applied in the fields of building materials and sound-absorbing materials, can solve the problems of low sound-absorbing performance and high cost, and achieve the effects of reducing transportation costs, rich material sources and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

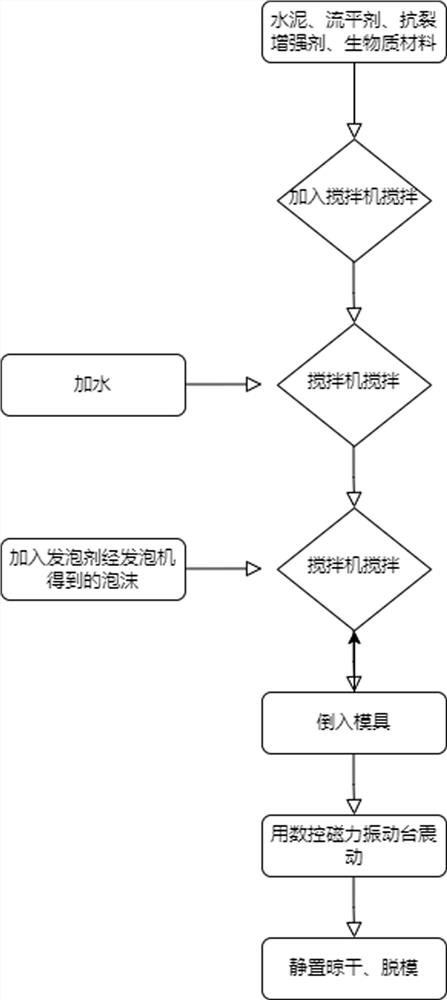

[0051] Each material in the formula of the present invention can be purchased commercially, and the preparation method of the biomass porous concrete sound-absorbing material provided by the present invention consists of figure 1 It can be seen that the following steps are included:

[0052] A. Mix cement, leveling agent, anti-crack enhancer, and biomass materials in proportion to make a dry material; add water to the dry material and continue stirring to make a slurry;

[0053] B. Dilute the foaming agent, foam the diluted foaming agent, mix and stir with the slurry to make a foaming slurry; wherein the foaming agent and water are diluted according to the volume ratio of 1:30;

[0054] C. Pour the foaming slurry into the mold, vibrate, and stand still to obtain a biomass-based porous concrete body, and then maintain it with the mold at room temperature for 12-36 hours, then demould, and dry.

[0055] Among them, the biomass material uses ammonium dihydrogen phosphate to acti...

Embodiment 1

[0067] The preparation method of biomass porous concrete sound-absorbing material comprises the following steps:

[0068] A. Mix cement, leveling agent, anti-crack enhancer, and biomass materials in proportion to make a dry material; add water to the dry material and continue stirring to make a slurry;

[0069] B. Dilute the foaming agent, foam the diluted foaming agent, mix and stir with the slurry to make a foaming slurry; wherein the foaming agent and water are diluted according to the volume ratio of 1:30;

[0070] C. Pour the foaming slurry into the mould, vibrate, and stand still to obtain a biomass-based porous concrete body, and then maintain it with the mold at room temperature for 36 hours, then demould, and dry.

[0071] The cement uses Portland cement 42.5,

[0072] The foaming agent uses sodium lauryl sulfate, sodium olefin sulfonate, and animal protein foaming agent with a mass ratio of 5:1:3;

[0073] The anti-crack reinforcing agent includes 30 parts of polyp...

Embodiment 2

[0081] The preparation method of biomass porous concrete sound-absorbing material comprises the following steps:

[0082] A. Mix cement, leveling agent, anti-crack enhancer, and biomass materials in proportion to make a dry material; add water to the dry material and continue stirring to make a slurry;

[0083] B. Dilute the foaming agent, foam the diluted foaming agent, mix and stir with the slurry to make a foaming slurry; wherein the foaming agent and water are diluted according to the volume ratio of 1:30;

[0084] C. Pour the foaming slurry into the mold, vibrate, and stand still to obtain a biomass-based porous concrete body, and then maintain it with the mold at room temperature for 12 hours, then demould, and dry.

[0085] The cement uses Portland cement 42.5,

[0086] The foaming agent uses sodium lauryl sulfate, sodium olefin sulfonate, and animal protein foaming agent with a mass ratio of 5:2:3;

[0087] The anti-crack reinforcing agent includes 20 parts of polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com