Hydrological monitoring buoy protection device

A protection device, hydrological monitoring technology, applied in buoys, collision avoidance, transportation and packaging, etc., can solve problems such as limited protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

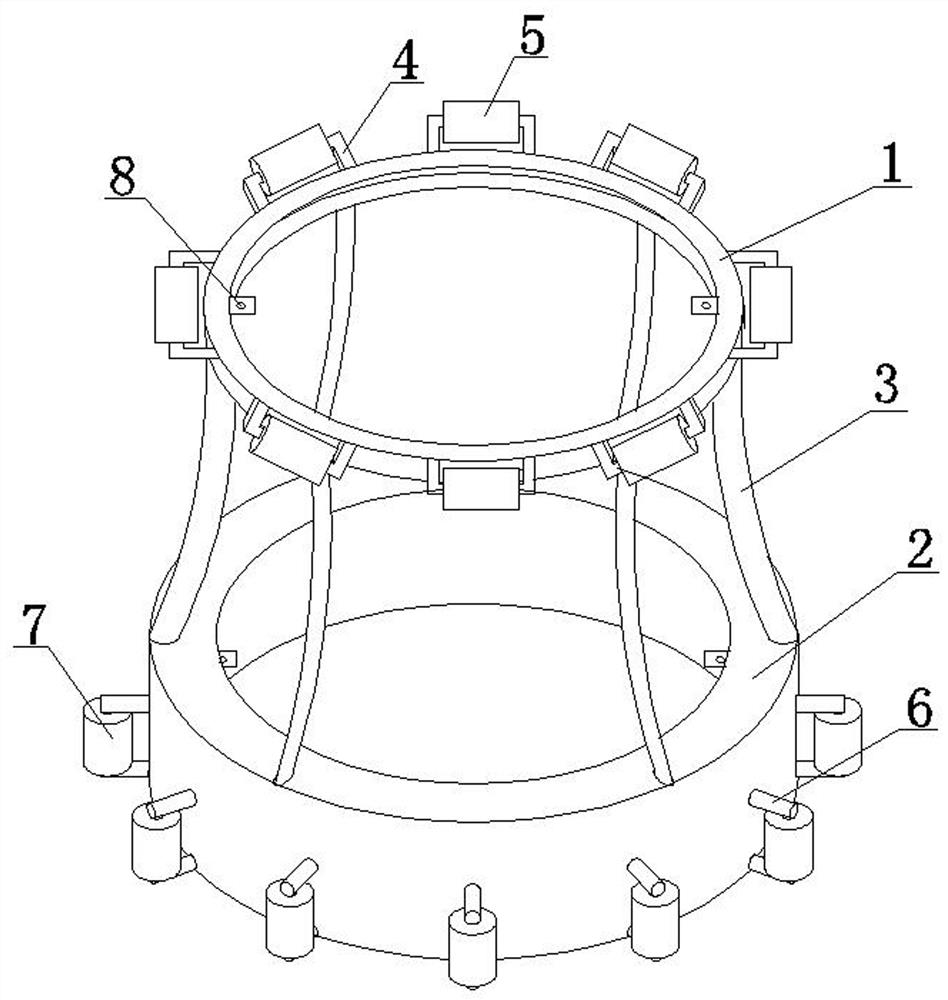

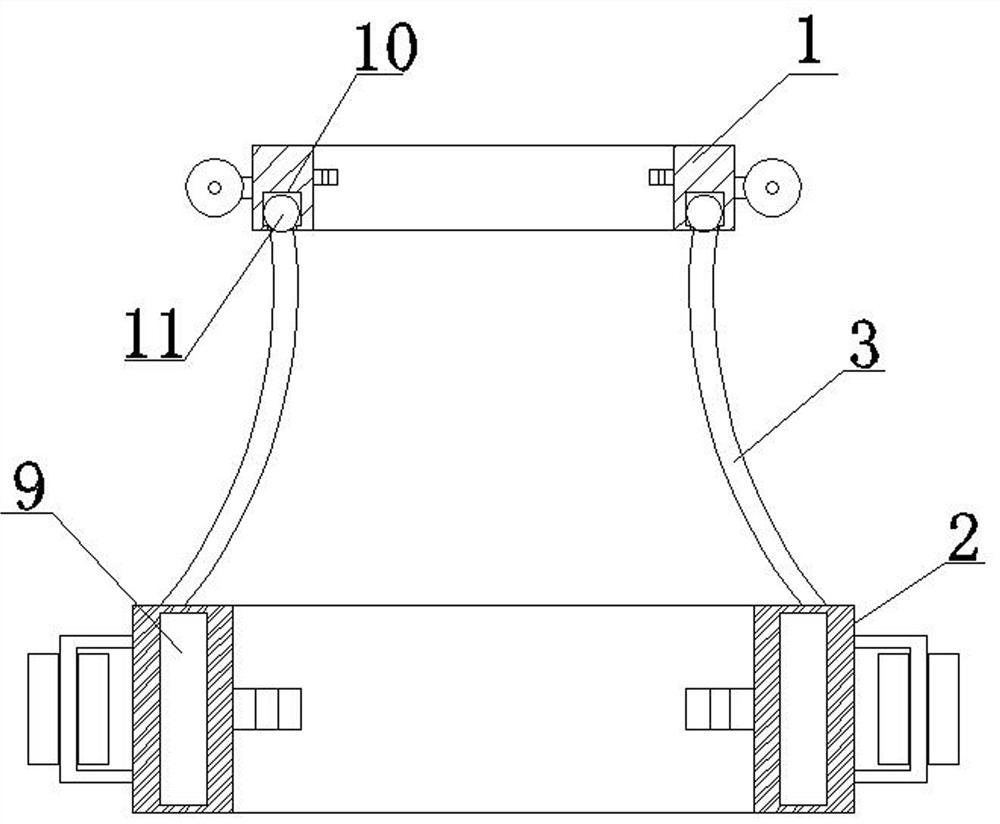

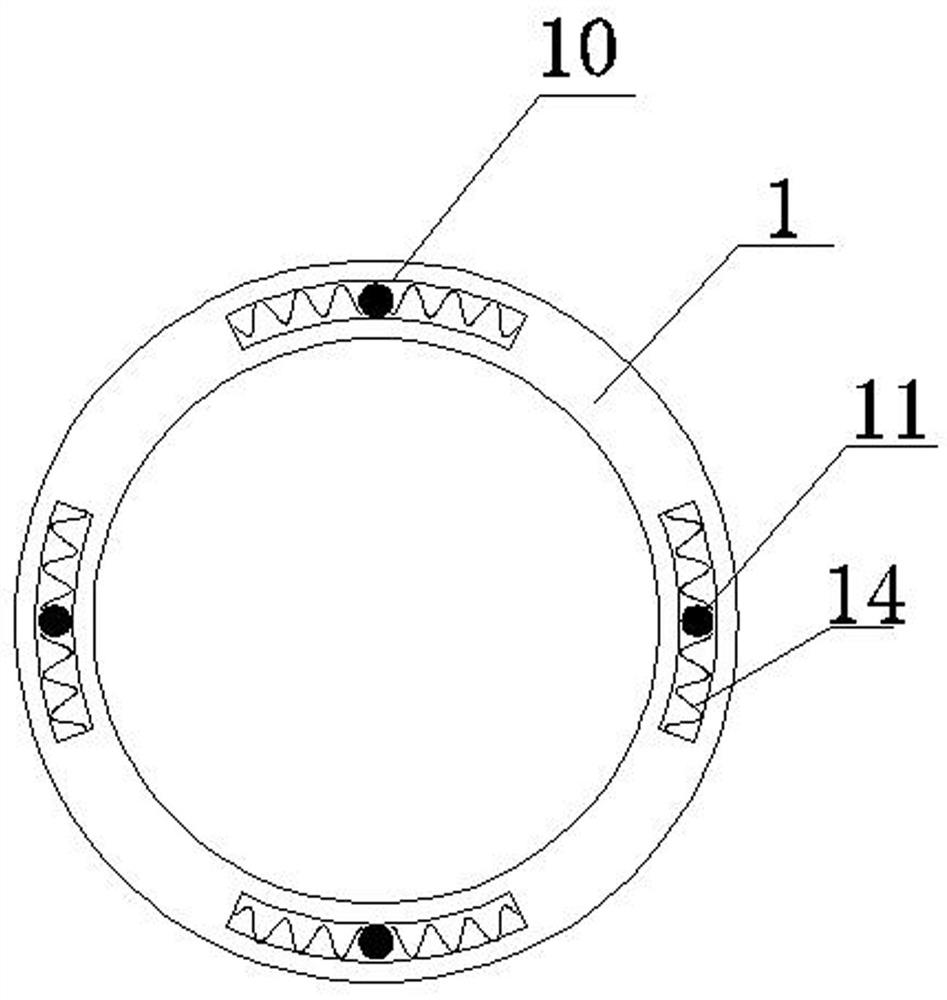

[0033] A hydrological monitoring buoy protection device, comprising a protective frame 1, a protective frame 2 2 and an arc-shaped support 3, the arc-shaped support 3 is movably connected with the lower part of the protective frame 1, and is fixedly connected with the upper part of the protective frame 2 2; the specific movable connection The method is as follows: a slideway 10 is set in the lower part of the protective frame-1, a slide block 11 matching the slideway 10 is set on the top of the arc-shaped support 3, and buffer springs 14 are set on both sides of the slide block 11, that is, under the action of an external force, the protective frame-1 There is a certain angle of rotation in the horizontal direction, and it can also be reset under the action of the buffer spring 14.

[0034] The outer wall of the protective frame-1 is evenly distributed with transverse brackets 4, and the rollers-5 are sleeved on the transverse brackets 4. Therefore, when subjected to impact fro...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is that the composite aluminum foam material is prepared by the following steps:

[0047] (1) Ingredients: Mg 1.2wt%, Si 0.6wt%, Ca 0.8wt%, Ti 1.2wt%, Cr 0.4wt%; the balance is Al;

[0048] Mix the above-mentioned Mg, Si, Al, Ti and Cr according to the ratio, heat and melt to form an alloy melt, and keep it warm for 30 minutes;

[0049] (2) Cool down to 720°C, add Ca and a small amount of AlN and glass fiber, and stir for 5-8 minutes;

[0050] (3) When the composite melt temperature reaches 690°C, add 1.5wt% blowing agent TiH to the composite melt 2 , stirred for 2 minutes, continued heat preservation and foaming for 10 minutes, and cooled to obtain the product.

[0051] The amount of AlN added is 4wt% of aluminum.

[0052] The compressive yield strength of the composite aluminum foam material sample prepared above was detected to be 35 MPa, and the porosity was 75%.

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is that the composite aluminum foam material is prepared by the following steps:

[0055] (1) Ingredients: Mg 1.3wt%, Si 0.8wt%, Ca 0.6wt%, Ti 1.5wt%, Cr 0.45wt%; the balance is Al;

[0056] Mix the above-mentioned Mg, Si, Al, Ti and Cr according to the ratio, heat and melt to form an alloy melt, and keep it warm for 30 minutes;

[0057] (2) Cool down to 720°C, add Ca and a small amount of AlN and glass fiber, and stir for 5-8 minutes;

[0058] (3) When the composite melt temperature reaches 700°C, add 1.8wt% blowing agent TiH to the composite melt 2 , stirred for 2 minutes, continued heat preservation and foaming for 10 minutes, and cooled to obtain the product.

[0059] The amount of AlN added is 4wt% of aluminum.

[0060] The compressive yield strength of the composite aluminum foam material sample prepared above was detected to be 32 MPa, and the porosity was 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com