Impulse input shaping crane anti-swing method

A pulse input, crane technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as lifting swings, cargo not arriving in time, affecting crane loading and unloading efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The trolley running horizontally in the lifting equipment, the rope connecting the load and the hoisting weight are regarded as a moving single pendulum system, such as figure 1 shown.

[0063] The following assumptions are made for the above model:

[0064] Assumption 1: The trolley and the load are regarded as particles with a certain mass, and the crane does not produce relative motion when it is stationary.

[0065] Assumption 2: The rope has negligible mass and is not stretchable in length.

[0066] Assumption 3: The influence of wind force and air resistance on the load is not considered.

[0067] According to Newton's laws of motion, the mathematical model of the system is:

[0068]

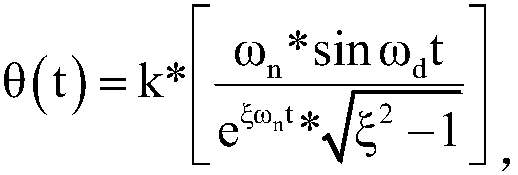

[0069] in k is the amplitude when the pendulum angle is finally stable, ω n is the oscillation frequency of the system, and ξ is the damping ratio.

[0070] The impulse response of the system is:

[0071]

[0072] By giving impulse responses of different amplitudes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com