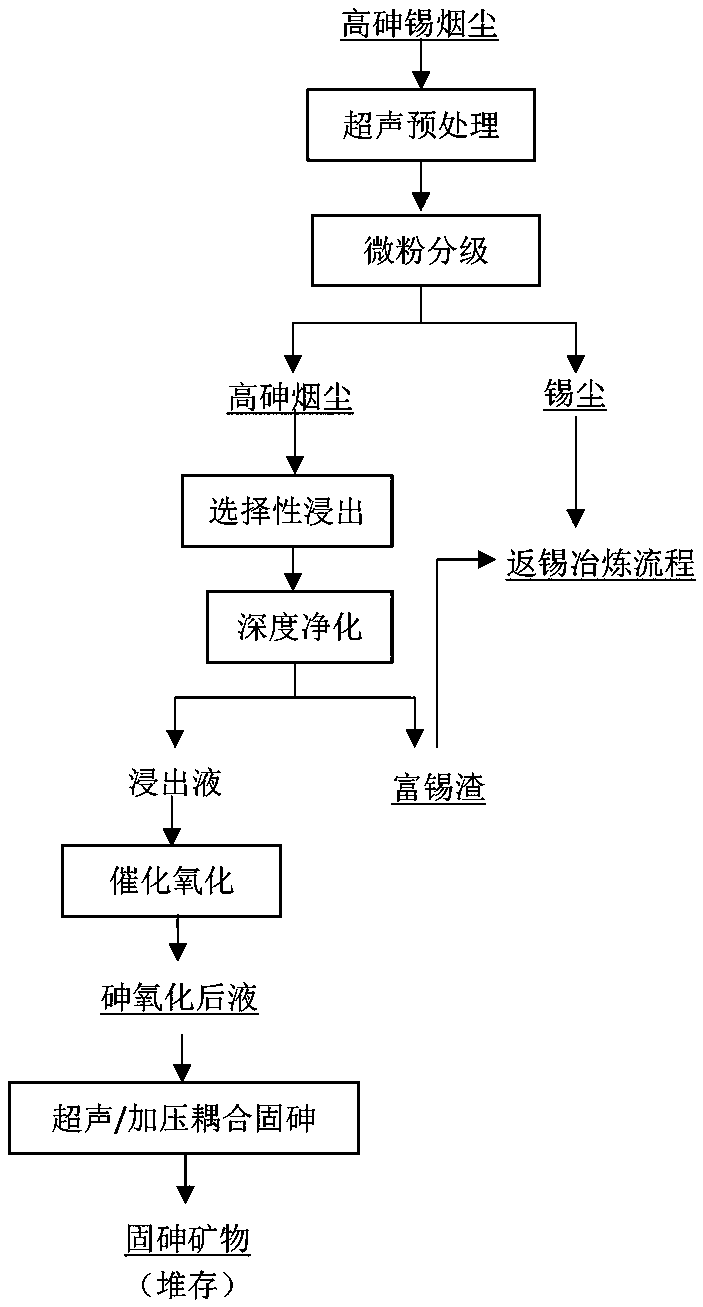

Mineralization arsenic fixation and tin recovery synergetic method for high-arsenic tin smoke

A technology of mineralization and soot, applied in the direction of improving process efficiency, etc., can solve problems such as low comprehensive recovery rate of valuable elements, limited market for arsenic products, hidden safety hazards, etc., and achieve elimination of hidden dangers of arsenic pollution, low cost, and reduced material volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Taking the rotary kiln dust of a tin smelting enterprise in Yunnan as an example, it contains the following main components in terms of mass percentage: Sn 9.42%, As 50.85%, Pb 11.37%. The arsenic-containing fume from tin smelting was placed in a closed ultrasonic equipment for pretreatment. The ultrasonic power was 2k W and the treatment time was 20 minutes. The soot after ultrasonic treatment is separated by eddy current micro-powder classification equipment, the power is 2.5 kW, and the feeding rate is 8 kg / h. See Table 1 for the content.

[0040] Table 1 Particle size distribution and element content of rotary kiln dust classification treatment

[0041] category

Particle size / μm

Mass fraction / %

As / %

Sn / %

Level 1

15~74

25.3

11.4

32.6

level 2

5~15

19.9

32.6

7.53

Level 3

≤5

54.8

67.8

1.32

[0042] The ≤5μm ultra-fine dust obtained by classification is placed in a pressurized reacto...

Embodiment 2

[0045] Taking fuming furnace dust from a tin smelting enterprise in Yunnan as an example, it contains the following main components in terms of mass percentage: Sn 4.97%, As 28.25%, Pb 15.26%. Take the high-arsenic tin fume and place it in a closed ultrasonic equipment for pretreatment. The ultrasonic power is 2k W and the treatment time is 20 minutes. The soot after ultrasonic treatment is separated by eddy current micro-powder classification equipment, the power is 2.5kW, and the feeding rate is 8 kg / h. The contents are shown in Table 2.

[0046] Table 2 Particle size distribution and element content of fuming furnace dust after classified treatment

[0047] category

Particle size / μm

Mass fraction / %

As / %

Sn / %

Level 1

15~74

26.8

5.42

12.7

level 2

5~15

21.4

22.6

3.23

Level 3

≤5

51.8

37.2

0.37

[0048] Take the ultra-fine smoke dust of ≤5μm obtained by classification in a pressurized react...

Embodiment 3

[0051] A method for mineralizing high-arsenic tin fume to fix arsenic and recover tin synergistically, comprising the following steps:

[0052] 1) Ultrasonic pretreatment: Ultrasonic treatment is performed on high-arsenic tin fumes under airtight conditions. The ultrasonic power is 2000W, and the pretreatment time is 30 minutes. Crushing and dispersing; the high-arsenic tin fume is arsenic-containing fume from a tin smelting rotary kiln, with an arsenic content of 28% and a tin content of 4%.

[0053] 2) Micro-powder classification: continue to carry out micro-powder classification of high-arsenic tin fumes, and divide high-arsenic tin fumes into ultra-fine fumes, comprehensive fumes and coarse fumes according to particle size distribution. Metal tin, the comprehensive fume is returned to the ultrasonic pretreatment; the micro-powder classification treatment is to put the fume into the powder collection system respectively according to the particle size distribution standard u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap