Film formation method, film formation apparatus, and storage medium

A film-forming method and film-forming device technology, which are applied in coating, gaseous chemical plating, metal material coating process, etc., and can solve the problem of film thickness thinning in the center of the wafer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

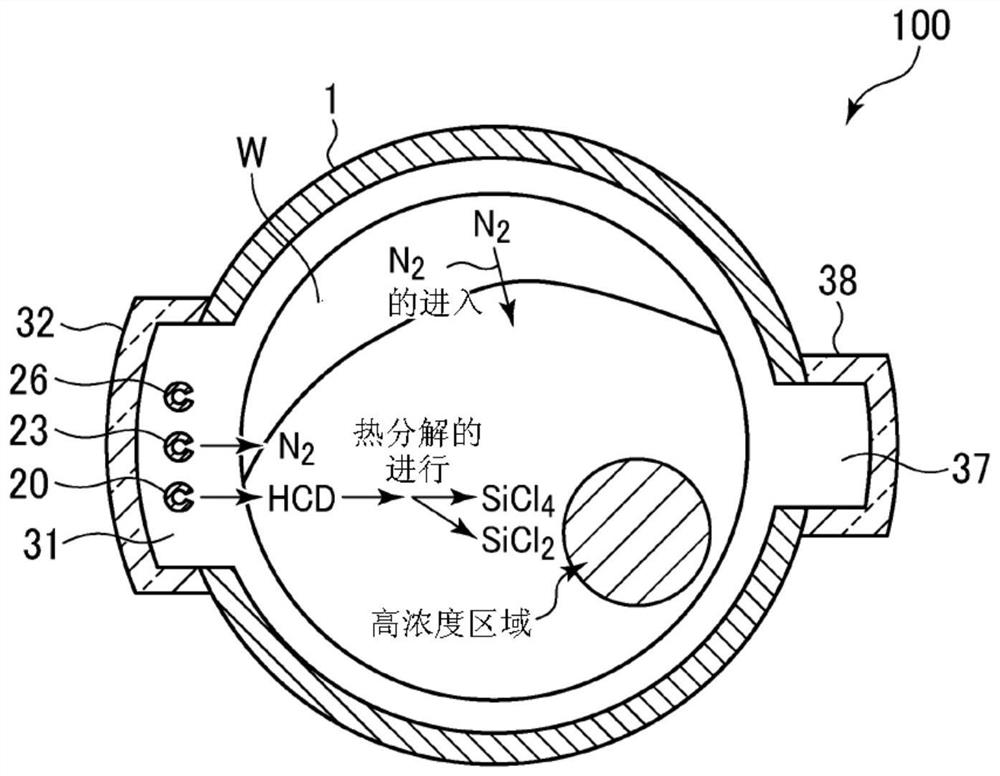

[0067] Here, a film-forming method capable of solving the above-mentioned problems was studied.

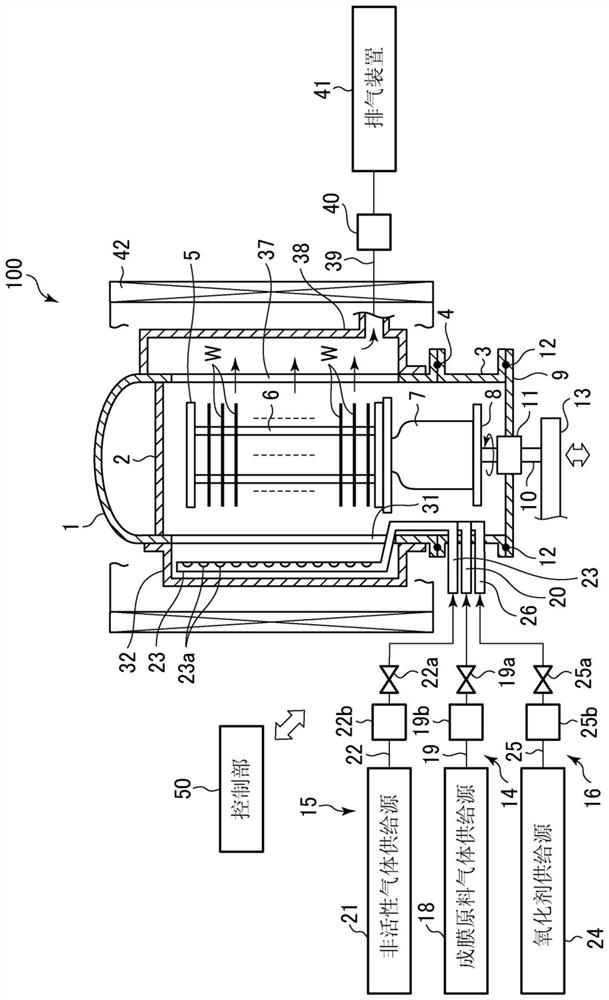

[0068] Hereinafter, a first embodiment of an apparatus for carrying out the method according to the present invention will be described.

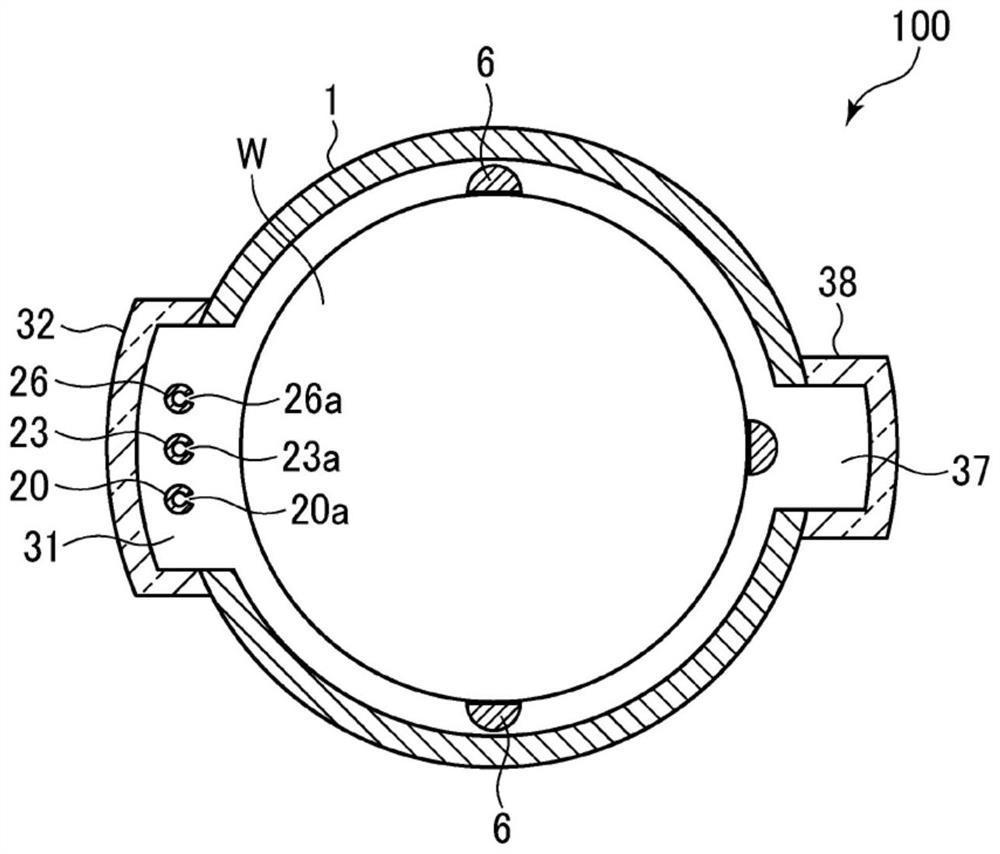

[0069] The inventors of the present invention have studied the method of adjusting the concentration distribution of the film-forming raw material gas in a batch-type vertical film-forming apparatus of the side-flow system or the cross-flow system, and found that when the film-forming material gas is supplied into the processing container 1, It is effective to spray the concentration distribution adjusting gas to a desired position in the processing container 1 .

[0070] Therefore, in this embodiment, gas distribution nozzles having the same structure as the gas distribution nozzles 20, 23, and 26 are arranged at desired positions around the wafer W in the processing chamber 1, and the gas ejected from the gas distribution nozzles The holes d...

no. 2 approach

[0084] Figure 7 It is a horizontal cross-sectional view showing the film forming apparatus according to the second embodiment. The film forming apparatus 104 of this embodiment has, in addition to figure 1 , figure 2 In addition to the constituent elements of the film forming apparatus 100 shown, all of the concentration-adjusting gas distribution nozzles 60A to 60F in the first to third examples of the first embodiment described above are provided around the processing chamber 1 . One end of gas pipes 61A to 61F is connected to these distribution nozzles 60A to 60F, respectively, and gas supply sources 62A to 62F for concentration adjustment are connected to the other ends of the gas pipes 61A to 61F, respectively. In addition, on-off valves 61Aa to 61Fa and flow rate controllers 61Ab to 61Fb are respectively provided in the respective gas pipes 61A to 61F.

[0085] In this embodiment, the ejection, stoppage, and ejection flow rate of the concentration adjustment gas fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com