High-strength anti-breaking plastic steel sheet pile

A fracture-resistant, plastic-steel technology, used in sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as easy water waste, and achieve the effects of preventing water waste, convenient collection, and simple and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

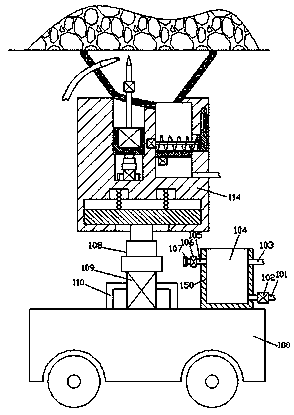

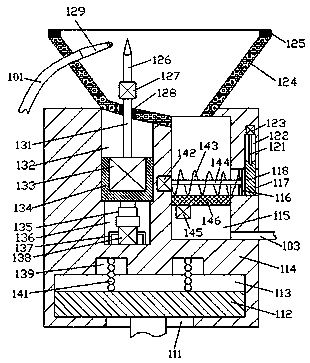

[0014] Combine below Figure 1-2 The present invention will be described in detail.

[0015] refer to Figure 1-2 , according to an embodiment of the present invention, a high-strength anti-break plastic sheet pile includes a cart 100, a first oil cylinder 109 is fixed on the cart 100, and a first oil cylinder 109 is installed on the upper end of the first oil cylinder with power cooperation. Piston rod 108, the top of the first piston rod 108 is provided with a pedestal 114, the top of the pedestal 114 is fixed with a dust cover 124, and the base 114 at the bottom of the dust cover 124 is provided with a dust collector. chamber 115, the inner wall on the right side of the dust collection chamber 115 is communicated with a discharge chamber 117 that runs through the right end surface of the base frame 114, and a connecting arm 116 is fixed between the upper and lower end walls of the discharge chamber 117, and the dust collection chamber A first motor 142 is fixed in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com