Casting device for civil construction and concrete casting construction method

A technology of pouring device and concrete, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of long formwork process, cumbersome construction process, and many formwork openings, etc. Wide range of properties, easy to vibrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

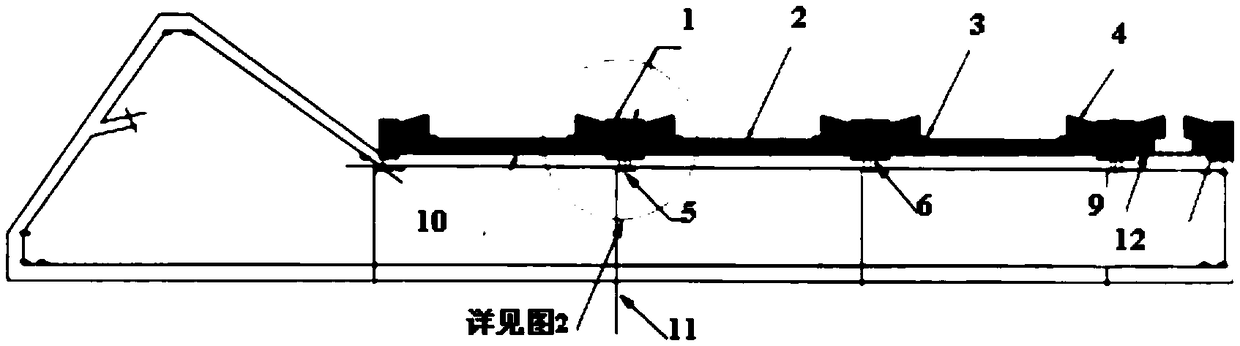

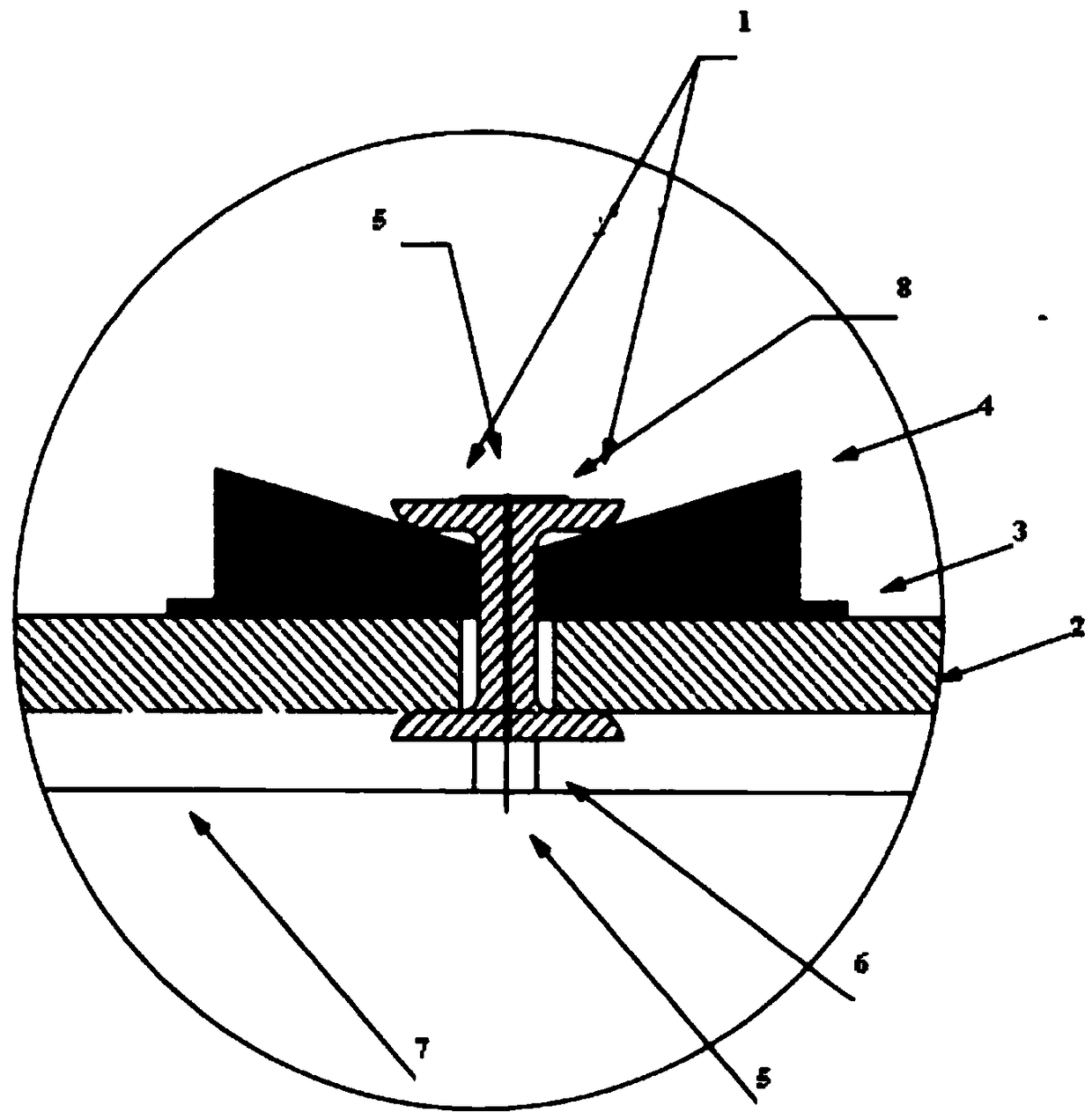

[0029] see Figure 1-2 , a kind of watering device for civil construction, comprising: 10# channel steel 1, as the slope concrete buckle form track, the bottom of the channel steel and the top surface of the structural slope are at the same height level; The braces 6 and 5 run through the top and bottom of the wooden wedge 4 and are respectively arranged symmetrically. The braces 6 are arranged at the bottom of the main buckle mold 2. The braces 5 and the braces 6 are effectively welded to the structural main reinforcement 7 to fix the channel steel 1 , in order to facilitate the removal of the channel steel 1, it is advisable to be firm and not burst during welding; the main buckle mold 2, the main buckle mold 2 snaps into the groove of the channel steel 1 and sticks to the lower bottom, and the top of the main buckle mold 2 snaps into the Rubber tube 3, and adopt wooden wedge 4 to be wedged in the track of channel steel 2 above rubber tube 3, wedge tight, under the situation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com