Tunnel lining structure using concrete filled steel tubes and laminated plates and construction method thereof

A technology of concrete filled steel tubes and steel tubes, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems that the steel arch and shotcrete are difficult to work together at the same time, other tunnel processes and transportation interference, and the poor adaptability of special-shaped sections, etc. Achieve significant economic value and comprehensive benefits, shorten the construction period, and reduce the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

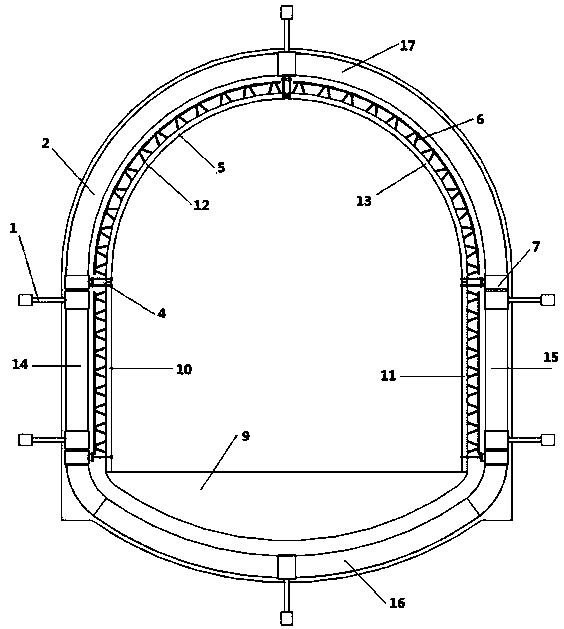

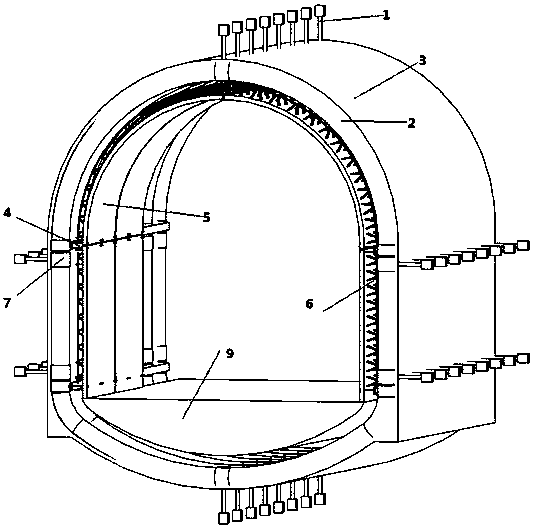

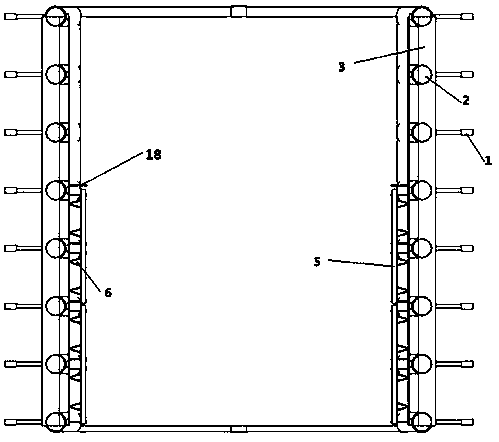

[0042] Embodiment 1: as Figure 1-5 As shown, a tunnel lining structure using concrete-filled steel tubes and laminated slabs. The composite slabs are installed with the concrete-filled steel tube arch frame as the support. The longitudinal and circumferential steel bars are bound on the truss bars of the laminated slabs, and then concrete is poured to form the secondary lining structure of the tunnel.

[0043] Further, the tunnel lining structure using steel pipe concrete and laminated slabs in the present invention specifically includes anchor connectors 1, steel pipe arches 2, steel mesh shotcrete 3, laminated slab supports 4, laminated slabs 5, and laminated slab truss bars 6;

[0044] Before the construction of the tunnel, the steel pipe arch frame 2 is prefabricated in sections outside the tunnel, the laminated plates 5 are prefabricated in pieces, and the anchor connectors 1 are reserved in the surrounding rock, and the prefabricated steel pipe arch frame 2 is transporte...

Embodiment 2

[0062] Example 2, such as Figure 1-5 As shown, a tunnel lining structure and construction method using steel pipe concrete and laminated slabs, this embodiment is the same as embodiment 1, wherein:

[0063] Further, the steel pipe arch 2 adopts a seamless round steel pipe with a diameter of 25 cm or a square steel pipe with a side length of 25 cm, the thickness of the steel pipe is 2 cm, and the steel pipe arch 2 is fixed to the initial support of the tunnel by the pre-embedded anchor connector 1 Instead of the grid steel frame or I-shaped steel frame in the primary support, the distance between each steel pipe arch frame 2 is 1.5m. The specific parameters depend on the type of tunnel surrounding rock and are determined by calculation or engineering analogy.

[0064] Further, the longitudinal width of the laminated board 5 is equivalent to the distance between the three steel pipe arches 2; the thickness of the laminated board is 8 cm; the inside of the laminated board 5 is m...

Embodiment 3

[0065] Example 3, such as Figure 1-5 As shown, a tunnel lining structure and construction method using steel pipe concrete and laminated slabs, this embodiment is the same as embodiment 1, wherein:

[0066] Further, the steel pipe arch 2 adopts a seamless round steel pipe with a diameter of 20cm or a square steel pipe with a side length of 20cm, the thickness of the steel pipe is 1.6cm, and the steel pipe arch 2 is fixed on the initial support of the tunnel by the embedded anchor connector 1. Instead of the grid steel frame or I-shaped steel frame in the primary support, the distance between each steel pipe arch frame 2 is 1.2m. The specific parameters depend on the type of tunnel surrounding rock and are determined by calculation or engineering analogy.

[0067] Further, the longitudinal width of the laminated board 5 is equivalent to the distance between the three steel pipe arches 2; the thickness of the laminated board is 6 cm; the inside of the laminated board 5 is mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com