Tunnel lining structure with steel tube concrete as skeleton and slip-form construction method

A technology of steel pipe concrete and shotcrete, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc. It can solve the problems of poor adaptability of special-shaped sections, long construction period, and large space occupation, and achieves the reduction of steel consumption, convenient and quick construction, and economical construction. template effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

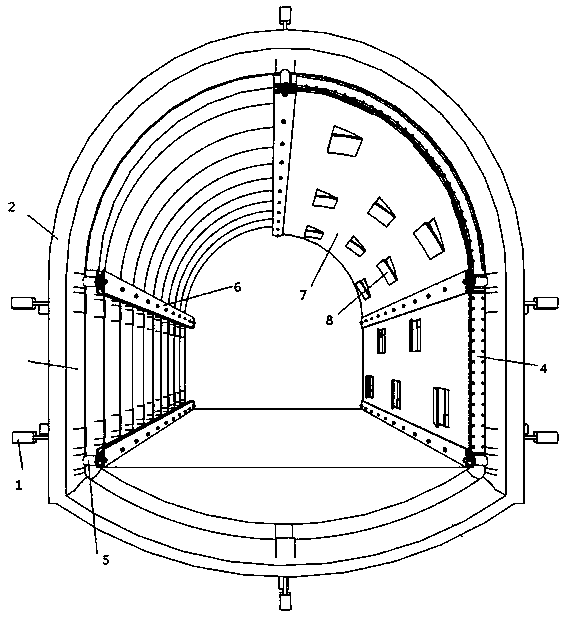

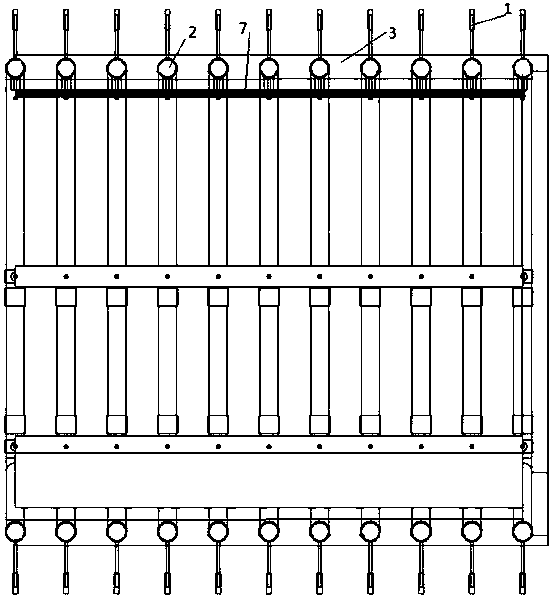

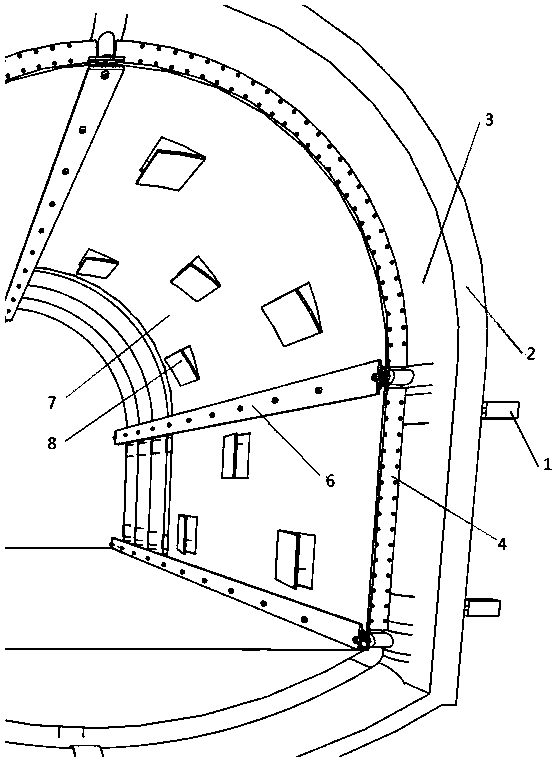

[0038] Embodiment 1: as Figure 1-4 As shown, a tunnel lining structure with steel pipe concrete as the skeleton includes anchor connector 1, steel pipe arch frame 2, steel mesh shotcrete 3, steel bar support 4, formwork track support device 5, formwork track 6, sliding formwork 7 and Openable window 8; before the tunnel construction, prefabricate the steel pipe arch frame 2 in sections outside the tunnel, reserve anchor connectors 1 in the surrounding rock, transport the segmentally prefabricated steel pipe arch frame 2 to the working face for assembly, and install the steel pipe arch frame Frame 2 is fixed close to the surrounding rock surface through anchor connector 1, high-strength concrete is poured into steel pipes through reserved pouring holes to form steel pipe concrete arches, steel mesh shotcrete 3 is constructed between and outside steel pipe concrete arches, The concrete-filled steel tube arch frame is fixed together with the steel mesh shotcrete; the formwork tr...

Embodiment 2

[0064] Embodiment 2: as Figure 1-4 As shown, a tunnel lining structure and a sliding form construction method with steel pipe concrete as the skeleton, this embodiment is the same as Embodiment 1, wherein:

[0065] Further, the steel pipe arch 2 adopts a seamless round steel pipe with a diameter of 25 cm or a square steel pipe with a side length of 25 cm, and the thickness of the steel pipe is 2 cm. Instead of the grid steel frame or I-shaped steel frame in the primary support, the distance between each steel pipe arch frame 2 is 1.5m. The specific parameters depend on the type of tunnel surrounding rock and are determined by calculation or engineering analogy.

[0066] Further, in the step Step1, the steel pipe arch 2 can be a seamless round steel pipe with a diameter of 25 cm, or a square steel pipe with a variable length of 25 cm, the wall thickness of the steel pipe is 2 cm, and the steel arch is prefabricated in four sections; The size is determined according to the inn...

Embodiment 3

[0067] Embodiment 3: as Figure 1-4 As shown, a tunnel lining structure and a sliding form construction method with steel pipe concrete as the skeleton, this embodiment is the same as Embodiment 1, wherein:

[0068] Further, the steel pipe arch 2 adopts a seamless round steel pipe with a diameter of 22cm or a square steel pipe with a side length of 22cm, and the thickness of the steel pipe is 1.7cm. In the support, instead of the grid steel frame or I-shaped steel frame in the initial support, the distance between the steel pipe arches 2 is 1.3m. The specific parameters depend on the type of tunnel surrounding rock and are determined by calculation or engineering analogy.

[0069] Further, in the step Step1, the steel pipe arch 2 can be a seamless round steel pipe with a diameter of 22cm, or a square steel pipe with a variable length of 22cm, the wall thickness of the steel pipe is 1.7cm, and the steel arch is prefabricated in four sections; the steel pipe arch The size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com