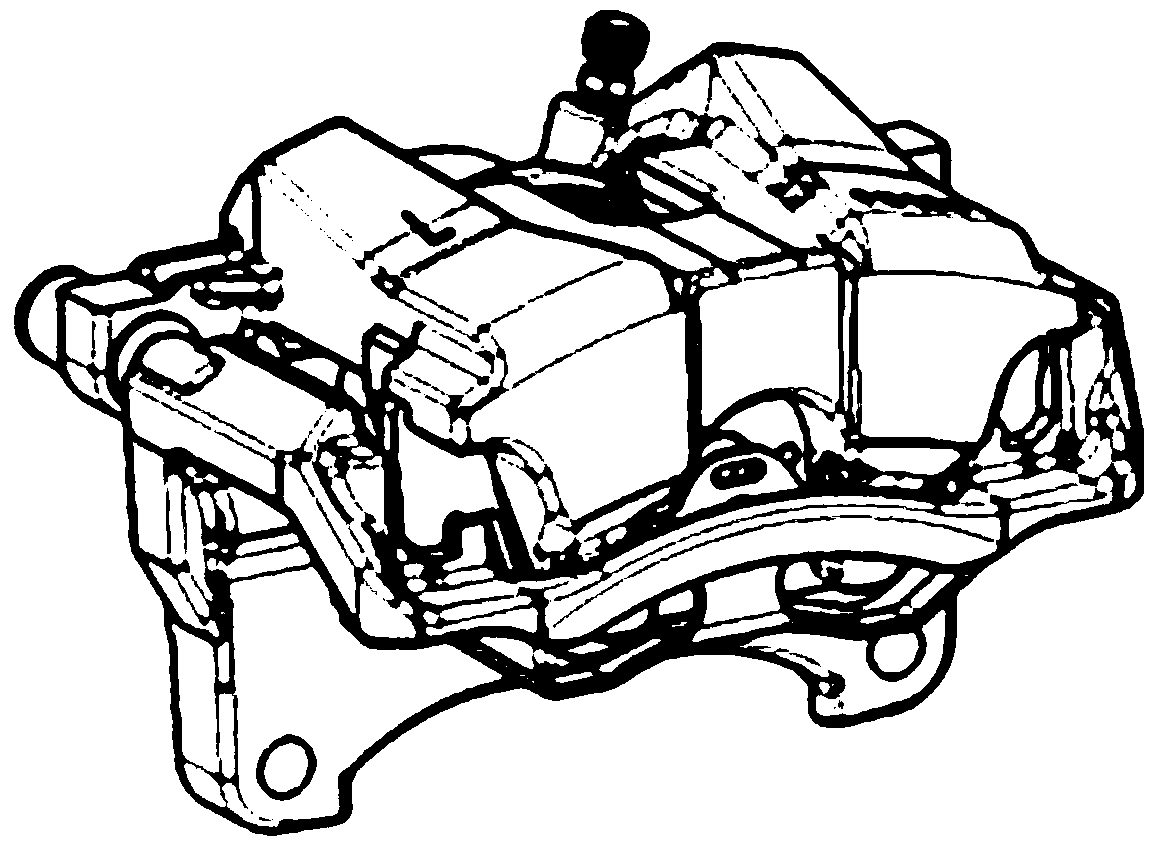

Eccentric only-pull structure type hydraulic brake callipers

A hydraulic braking and structural technology, applied in the direction of brake parts, brake types, gear transmission mechanisms, etc., can solve problems such as plane support clearance fit, small-span support instability, radial direction instability, etc., to achieve rigidity improvement , The effect of improving the stability of the machine and improving the noise condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described now in conjunction with accompanying drawing.

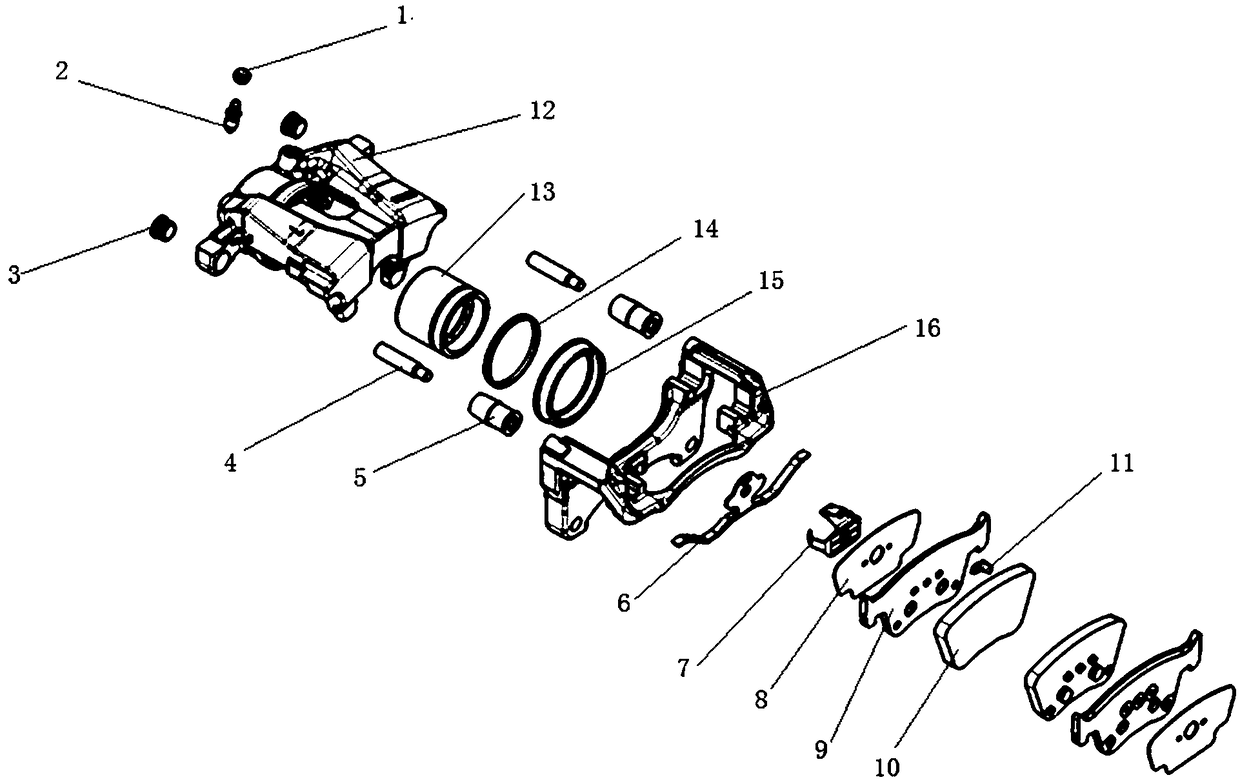

[0029] see Figure 1-Figure 2 , the present invention is an eccentric only pull structure hydraulic brake caliper, including guide pins, buffer sleeves, retaining springs, inner friction blocks, outer friction blocks, eccentric housings, pistons and only pull structural supports, and only pull structural supports 16 Fix the brake caliper on the steering knuckle of the chassis to transmit tangential force. The two sides of the eccentric housing 12 are connected with the pull-only structure bracket 16 with guide pins 4 and buffer sleeves 5. The eccentric housing Adopt retaining spring 6 to connect between 12 and outer friction block, adopt another retaining spring 7 to connect between inner friction block and piston 13.

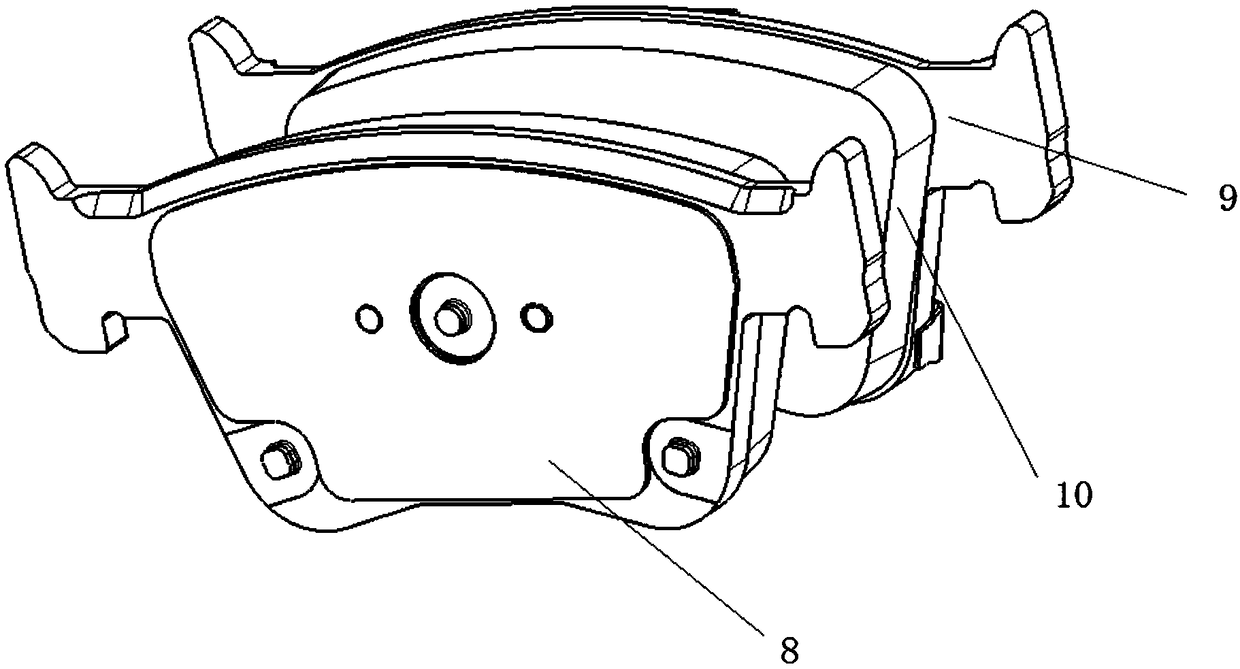

[0030] see image 3 , the outer friction block and the inner friction block both include a damping sheet 8 , a back plate 9 and a friction material 10 . se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com