Double-guide-rail tuned mass damper (TMD) energy-consuming vibration damper for wind power generator unit

A technology of wind power generators and vibration damping devices, applied in the field of structural vibration reduction, can solve problems such as frequency drift of TMD damping devices, energy consumption and vibration reduction of wind power towers, etc., achieve good vibration reduction effects, good energy consumption performance, and structural The vibration response reduction effect of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

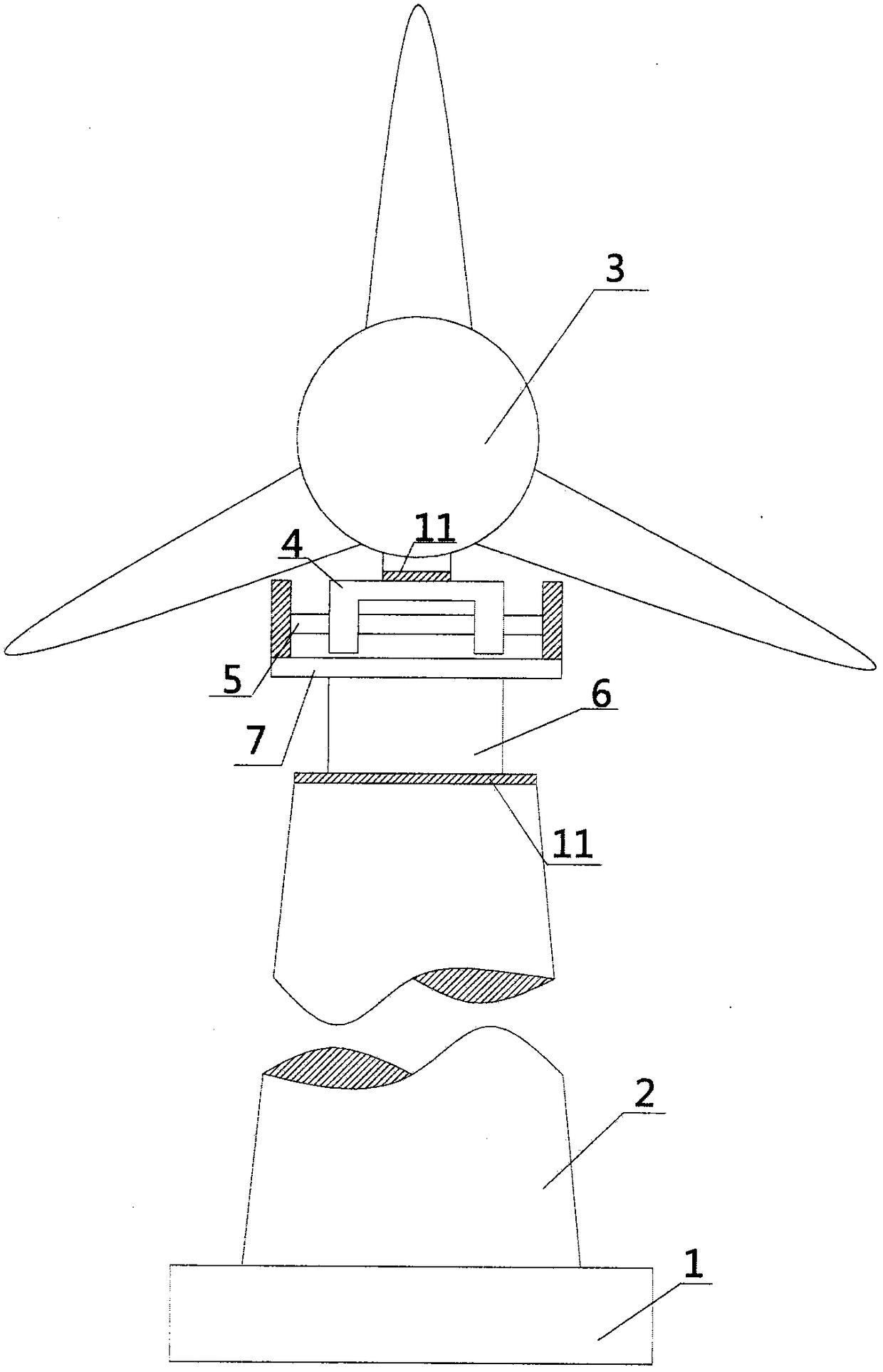

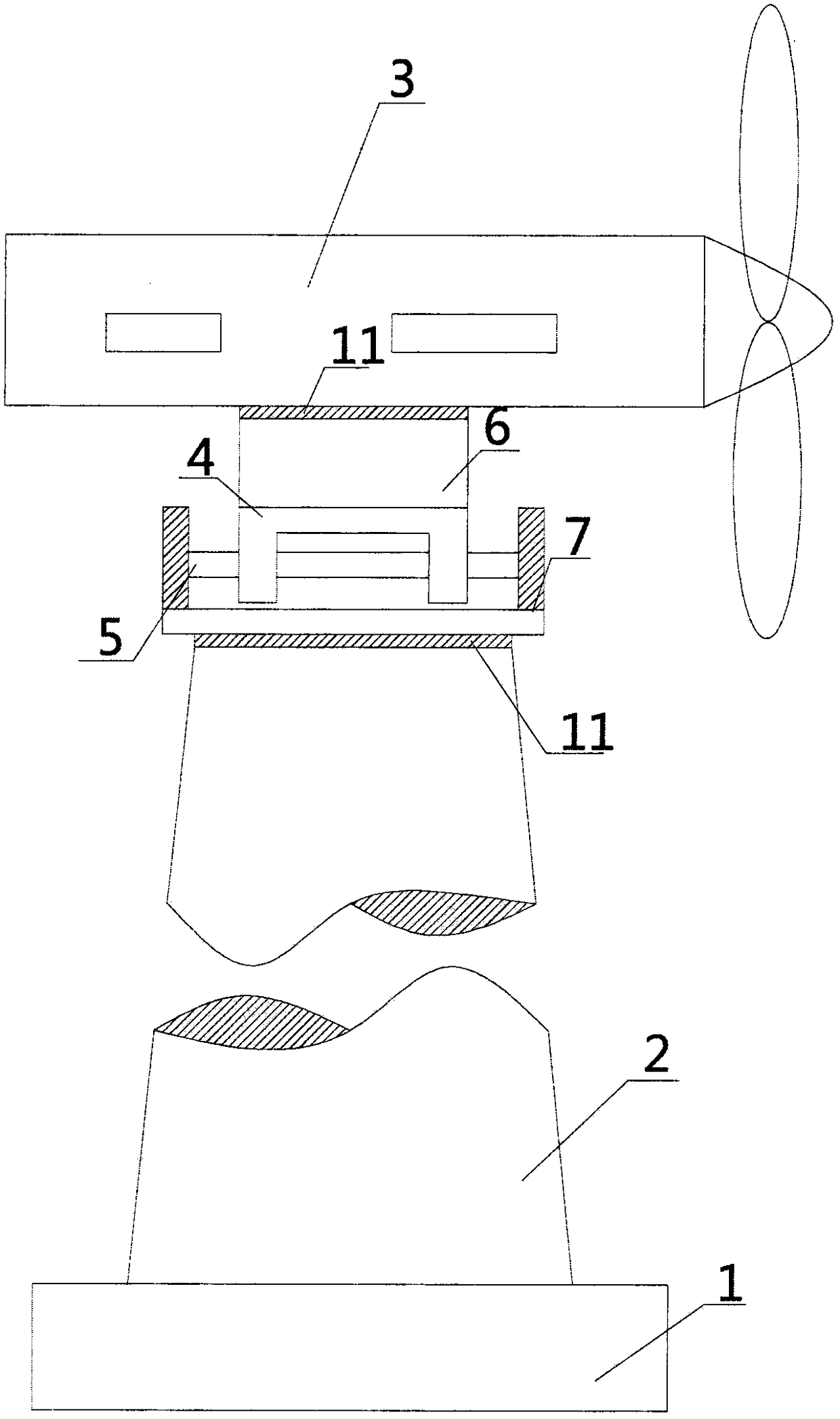

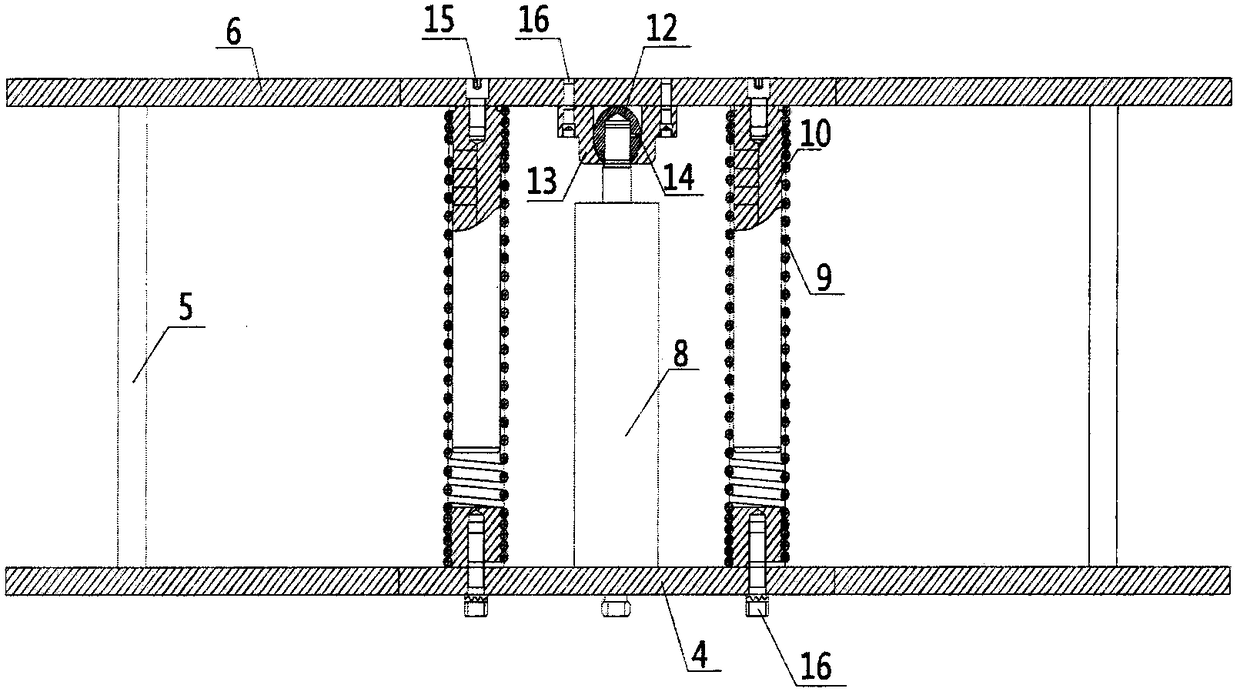

[0021] figure 1 and figure 2 It is a schematic diagram of the present invention applied to wind power generators. Such as figure 1 and figure 2 As shown, the double-rail TMD energy-dissipating vibration damping device according to the present invention mainly includes a cross slide, a viscous damper 8, a spring 9, etc., aiming at the problem that the traditional wind tower vibration damping device is inconvenient to install and the stroke of the damper is limited. The damper of the present invention changes the connection mode between the tower and the upper structure, and uses the cross slide to satisfy the vibration control of the tower system in the entire plane, so as to realize mutual braking between the upper structure of the wind turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com