Phase modulation device, pulse tube refrigerator and phase modulation method based on eddy current damping

An eddy current damping, pulse tube refrigerator technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problem of inability to provide suitable pulse tube refrigerators, and achieves overcoming insufficient phase modulation capability, efficient work, and high efficiency. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

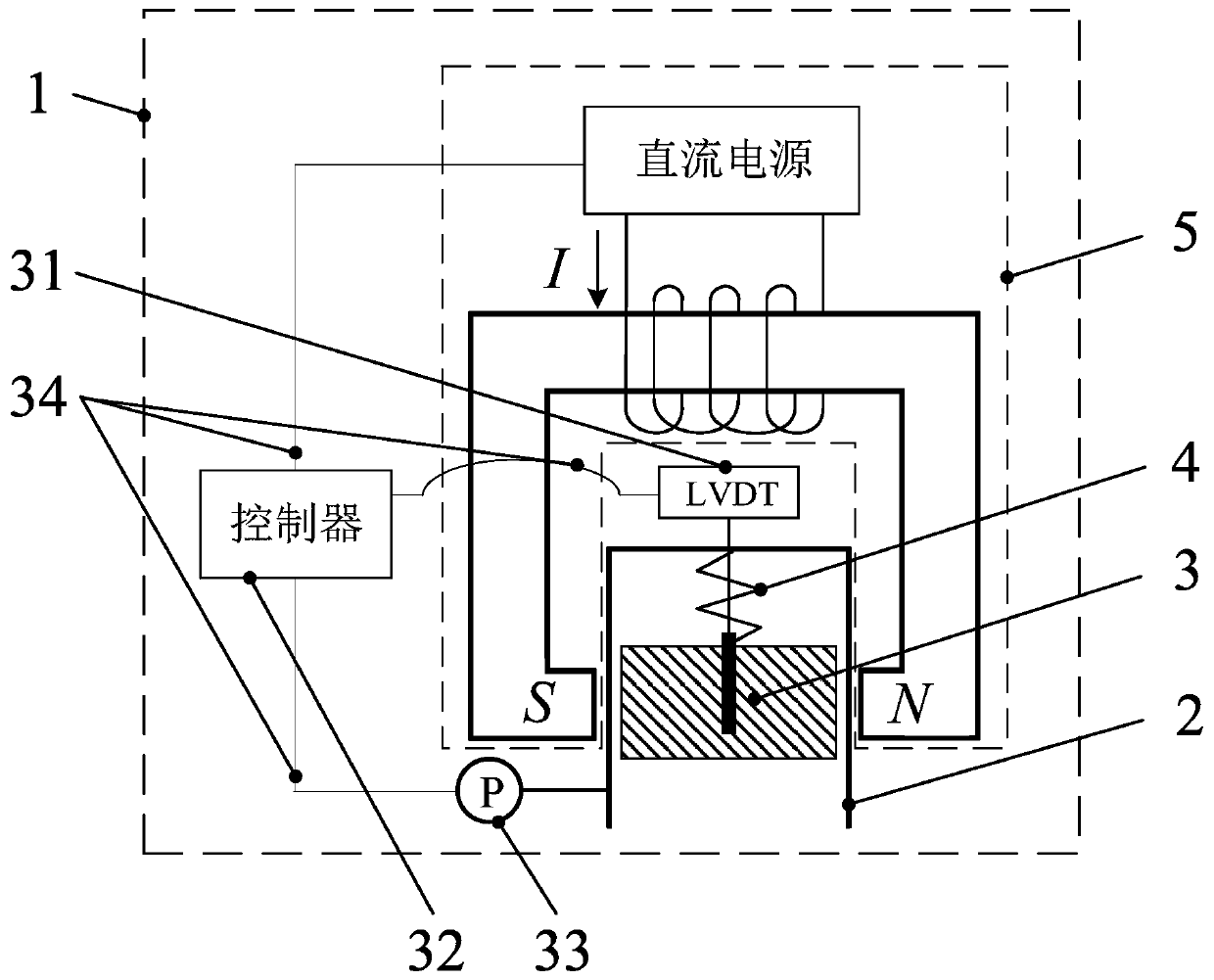

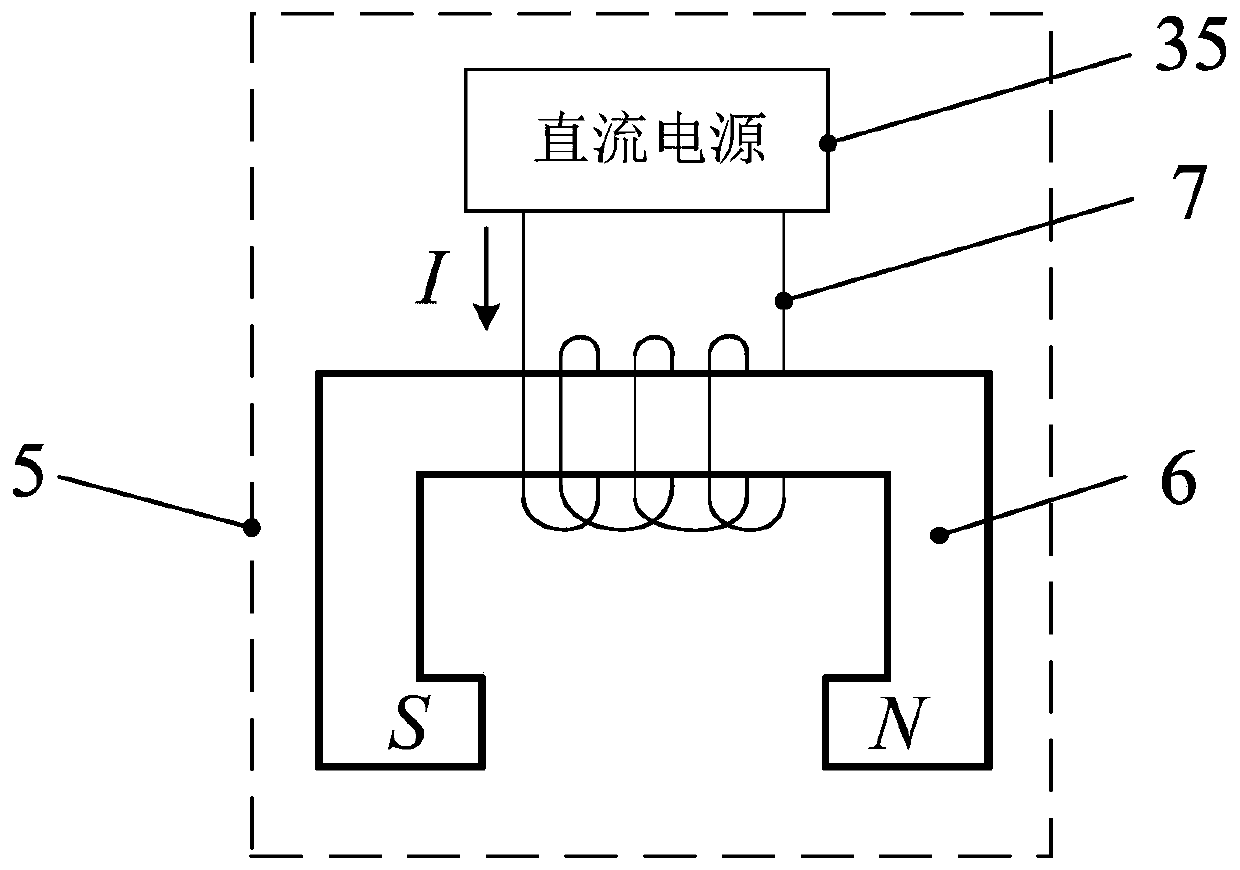

[0059] Such as figure 1 As shown: a refrigerator impedance active phase modulation device 1 based on eddy current damping includes: a casing 2, a piston 3 connected in the casing 2 through a spring 4, a magnetic field generating device 5 placed outside the casing 2, and a piston 3 in phase Connect the displacement sensor 31 for detecting the displacement of the piston, the pressure sensor 33 arranged at the front of the piston 3 for detecting the pressure on the piston, and the sensor connected to the magnetic field generator 5, the displacement sensor 31 and the pressure sensor 33 through the data connection line 34 The controller 32 can control the eddy current damping force received by the piston 3 by changing the magnetic field strength of the magnetic field generating device 5, so as to realize the active adjustment of the impedance of the refrigerator.

[0060] Wherein, the shell is made of non-ferromagnetic material, and various materials meeting requirements can be use...

Embodiment 2

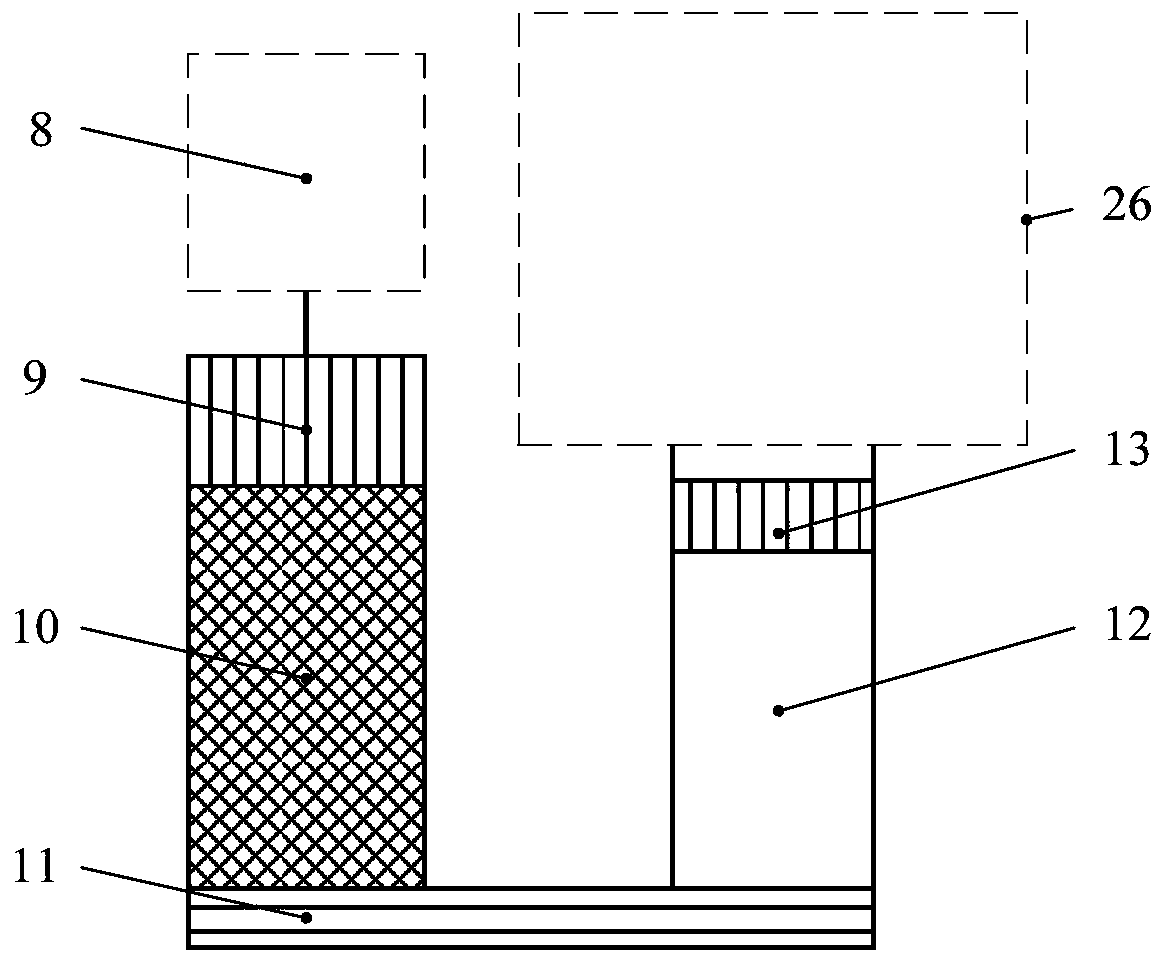

[0080] Such as image 3 Shown: A pulse tube refrigerator with an active phasing device for refrigerator impedance based on eddy current damping includes: a compression device 8, a heat exchanger at the hot end of the regenerator 9, a regenerator 10, and a heat exchanger at the cold end 11, The pulse tube 12 , the heat exchanger 13 at the hot end of the pulse tube, and the phase modulation device 26 , the phase modulation device 26 is the active phase modulation device 1 of refrigerator impedance based on eddy current damping described in Embodiment 1.

[0081] The above-mentioned components are connected as follows: the compression device 8 is sequentially connected to the heat exchanger 9 at the hot end of the regenerator, the regenerator 10, the heat exchanger 11 at the cold end, the pulse tube 12, and the heat exchanger 13 at the hot end of the regenerator through pipelines. and the phase modulating device 26; the regenerator 10 and the vessel 12 can be arranged in a U-shap...

Embodiment 3

[0087] Such as Figure 4 Shown: a multi-stage pulse tube refrigerator with an active phasing device for refrigerator impedance based on eddy current damping includes: a compression device 8, a heat exchanger at the hot end of the regenerator 9, a first-stage regenerator 14, The first-stage cold-end heat exchanger 15, the first-stage pulse tube 16, the first-stage pulse tube hot-end heat exchanger 17, the first-stage phasing device 27, the second-stage regenerator 18, and the second-stage cold end The heat exchanger 19, the second-stage pulse tube 20, the second-stage pulse tube hot-end heat exchanger 21, and the second-stage phasing device 28, the first-stage phasing device 27 and the second-stage phasing device 28 At least one of them is the active phasing device 1 for refrigerator impedance based on eddy current damping described in Embodiment 1, and of course both of them can adopt the active phasing device 1 for refrigerator impedance based on eddy current damping describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com