Multi-scale fiber composite high temperature gas filter material and preparation method thereof

A high-temperature gas filtration and fiber composite technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor mechanical properties and poor filtration performance, and achieve improved mechanical properties, less energy loss, and improved interception effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

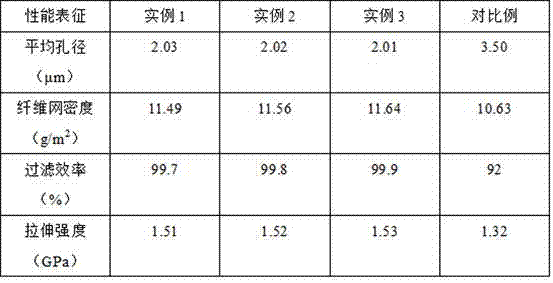

Examples

example 1

[0026] Take polyphenylene sulfide powder and put it into a vacuum drying oven, dry it to constant weight at 105°C, then take 80g of dried polyphenylene sulfide powder, 1.6g basalt fiber, 0.4g silane coupling agent KH-550, add In the twin-screw extruder, the masterbatch was obtained by melting, kneading, extruding and granulating at 280°C, and then the masterbatch was put into a spinning machine for melting and drawing to obtain modified polyphenylene sulfide fiber filaments. Take 12g of tetratitanate Add 80g of butyl ester to 10% acetylacetone-ethanol mixture, stir at 300r / min for 30min, then add 20g of absolute ethanol, 4g of 10% hydrochloric acid, 0.8g of copper sulfate pentahydrate powder, 1.6g of boric acid powder, continue to stir for 1 hour to obtain a mixed solution, take 40g of alkali-free glass fiber and soak in the mixed solution for 1 hour, take out the soaked fiber filaments and place them in a drying oven, dry them at 105°C to constant weight, and then transfer the...

example 2

[0028]Take polyphenylene sulfide powder and put it into a vacuum drying oven, dry it to constant weight at 107°C, then take 90g of dried polyphenylene sulfide powder, 1.8g basalt fiber, 0.45g silane coupling agent KH-550, add In the twin-screw extruder, the masterbatch was obtained by melting, kneading, extruding and granulating at 300°C, and then the masterbatch was put into a spinning machine for melting and drawing to obtain modified polyphenylene sulfide fiber filaments. Take 14g of tetratitanate Add butyl ester to 90g of 10% acetylacetone-ethanol mixture, stir at 350r / min for 35min, then add 23g of absolute ethanol, 5g of 10% hydrochloric acid, 0.9g of copper sulfate pentahydrate powder, 1.8g of boric acid powder, continue to stir for 1 hour to obtain a mixed solution, take 45g of alkali-free glass fiber and soak in the mixed solution for 1 hour, take out the soaked fiber filaments and place them in a drying oven, dry them at 107°C to constant weight, and then transfer the...

example 3

[0030] Take polyphenylene sulfide powder and put it in a vacuum drying oven, dry it at 110°C until it reaches constant weight, then take 100g of dried polyphenylene sulfide powder, 2.0g basalt fiber, 0.5g silane coupling agent KH-550, add In the twin-screw extruder, the masterbatch was obtained by melting, kneading, extruding and granulating at 320°C, and then the masterbatch was put into a spinning machine for melting and drawing to obtain modified polyphenylene sulfide fiber filaments. Take 15g of tetratitanate Add 100g of butyl ester to 10% acetylacetone-ethanol mixture, stir at 400r / min for 40min, then add 25g of absolute ethanol, 5g of 10% hydrochloric acid, 1.0g of copper sulfate pentahydrate powder, 2.0g of boric acid powder, continue to stir for 2 hours to obtain a mixture, take 50g of alkali-free glass fiber and soak in the mixture for 2 hours, take out the soaked fiber filaments and place them in a drying oven, dry them at 110°C to constant weight, and then transfer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com