Establishment method for steel box beam welding residual stress and structural stress coupling calculation model

A technology of structural stress and residual stress, applied in the direction of calculation, design optimization/simulation, special data processing application, etc., can solve the problems of low calculation accuracy and inaccuracy, and achieve the effect of efficient calculation, accurate results and simple modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

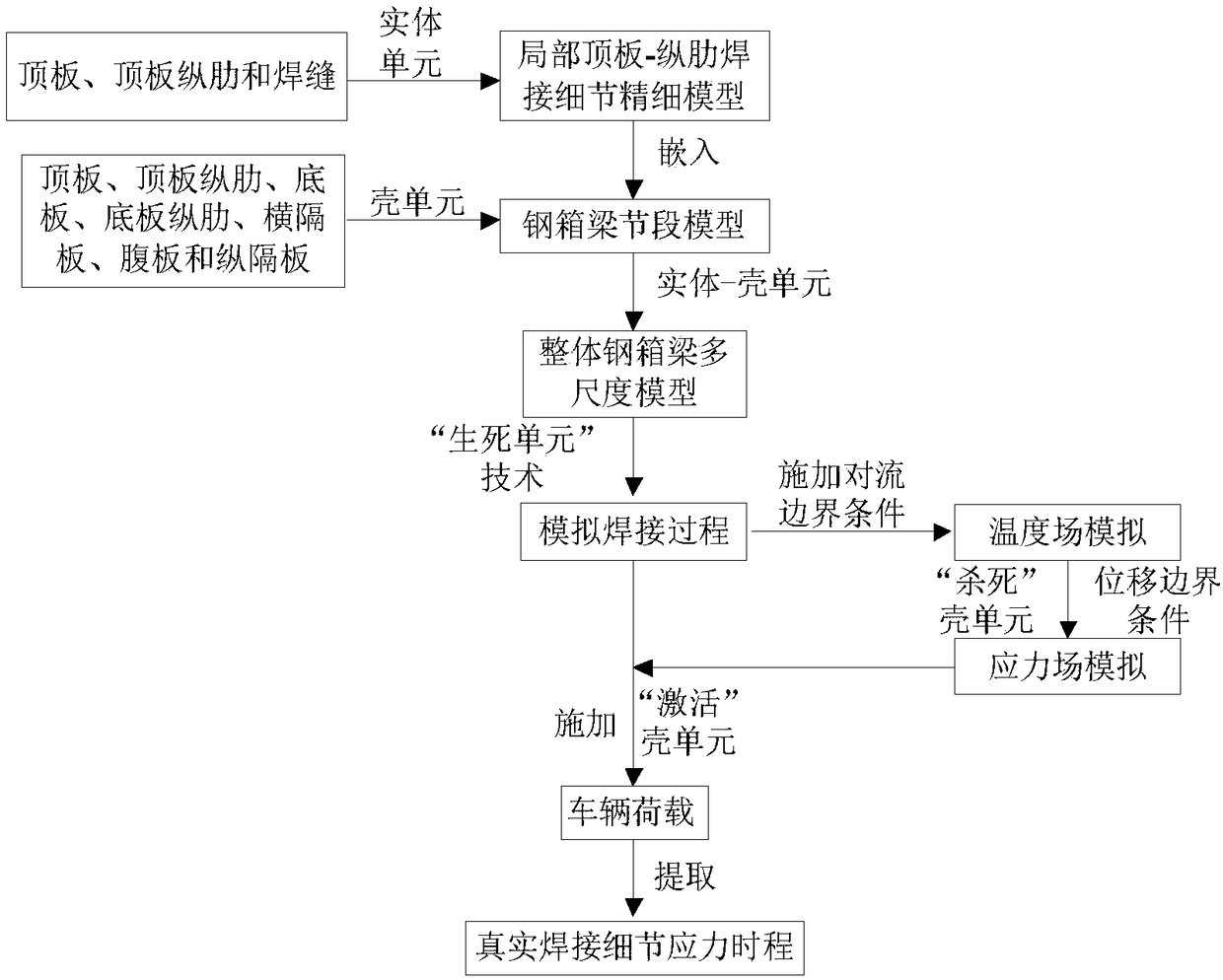

[0038] Such as figure 1 As shown, the present invention has designed a method for establishing a steel box girder welding residual stress and structural stress coupling calculation model, and the method specifically includes the following steps:

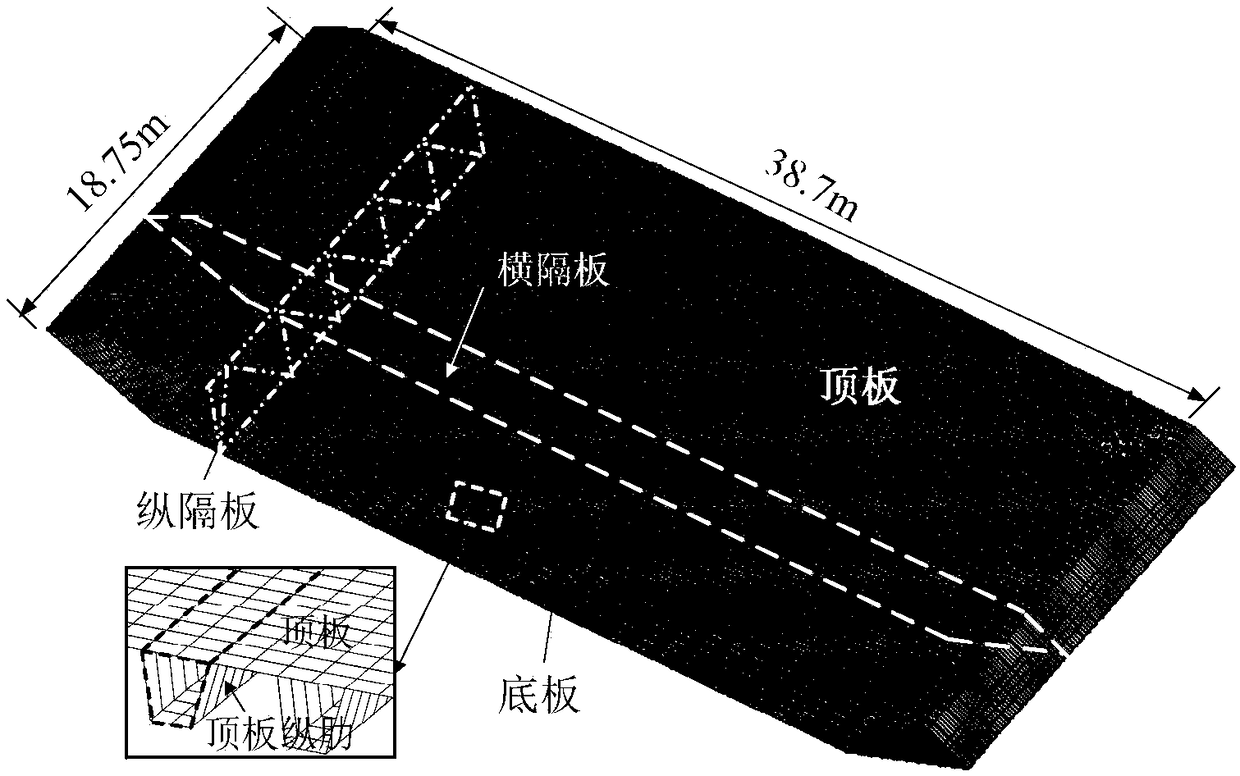

[0039] Step 1. Carry out limited simulation on the steel box girder system of long-span bridges, and establish a steel box girder segment model.

[0040] Based on ANSYS finite element analysis software, according to the design drawings and data of long-span bridge steel box girder structural system, the roof, roof longitudinal rib, bottom plate, bottom plate longitudinal rib, transverse diaphragm and web are all simulated by shell elements, and the mediastinal The plates are modeled with beam and shell elements according to the truss and solid web types, respectively.

[0041] In addition, the boundary conditions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com