Motor monitoring system based on machine learning

A technology of machine learning and motor monitoring, applied in the direction of motor generator testing, transmission system, neural learning methods, etc., can solve problems in professional fields, high-level motor mathematical models, lack of precise positioning of motor faults, etc., to achieve multiple Equipment monitoring, to achieve the effect of accurate monitoring of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content, steps and application of the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

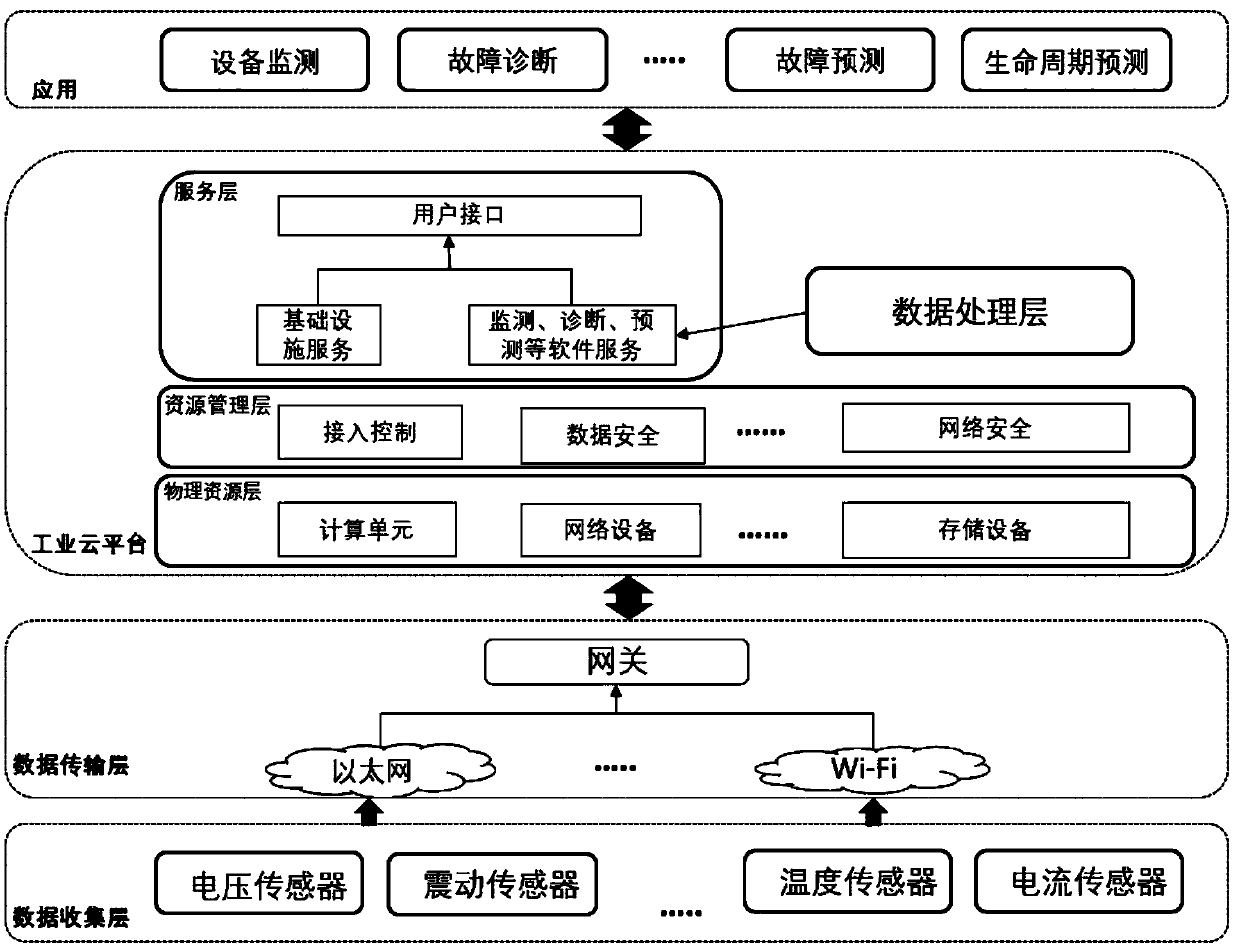

[0028] see figure 1 , the system architecture of the motor monitoring of the present invention includes: a data collection layer, a data transmission layer, an industrial cloud platform and an application layer, wherein:

[0029] The data collection layer is mainly physical equipment for data collection, including voltage sensors, current sensors, vibration sensors, temperature sensors, etc.

[0030] The data transmission layer mainly uses Ethernet or Wi-Fi for data transmission, and uploads the data to the industrial cloud platform through the gateway.

[0031] The industrial cloud platform consists of four parts: physical resource layer, resource management layer, service layer and data processing layer. The physical resource layer includes computing units, network devices and storage devices;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com