Electronic device and manufacturing method thereof

A technology of electronic devices and manufacturing methods, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as high equipment cost, limited density of electronic device components, and limited equipment manufacturing accuracy. Achieve the effect of increasing the density of component settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The electronic device and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference numerals.

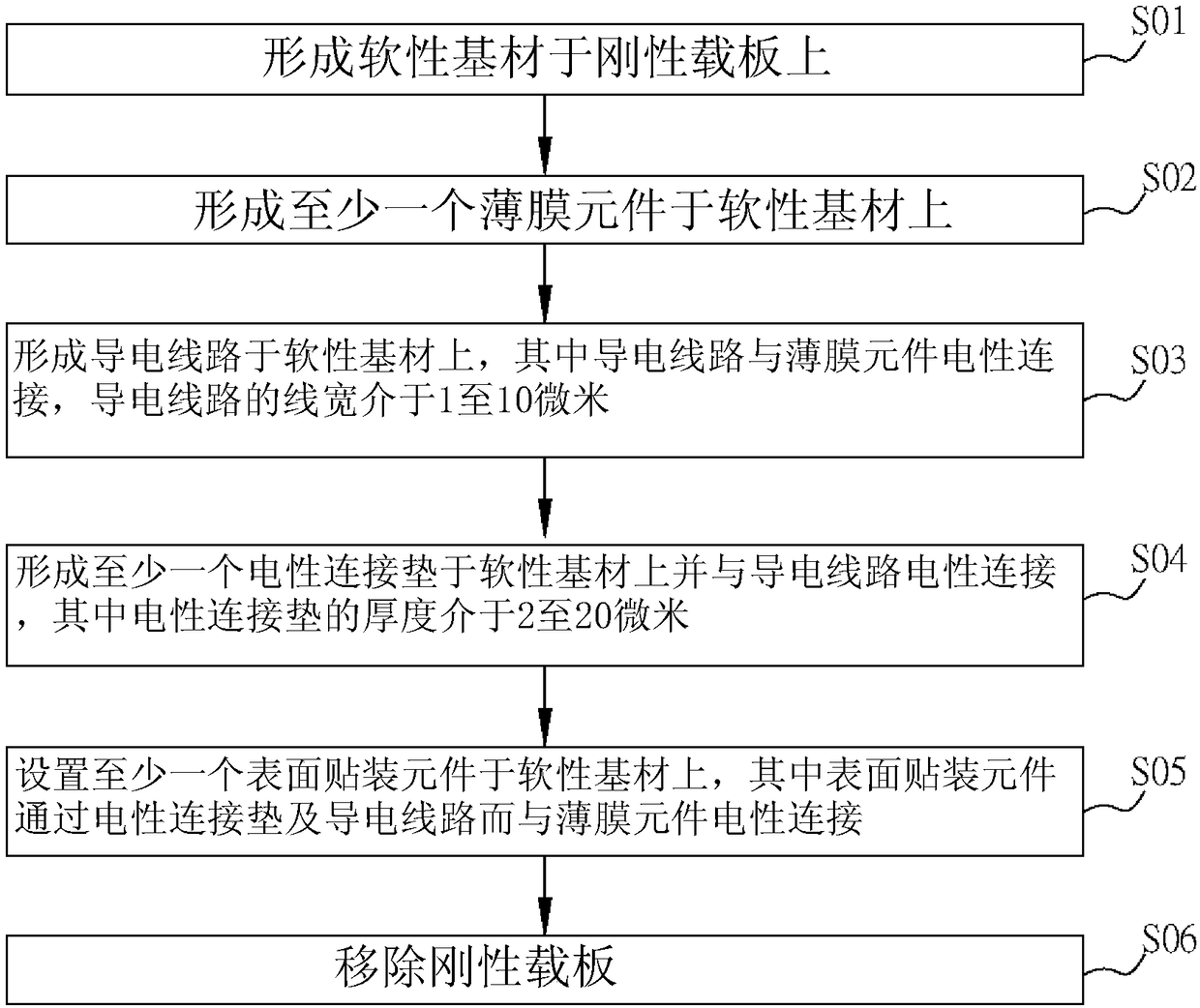

[0028] Please refer to figure 1 , which is a schematic flowchart of a method for manufacturing an electronic device according to a preferred embodiment of the present invention. The electronic device described in the following embodiments can be a light-emitting diode (LED) display, a micro-light-emitting diode display (Micro-LED Display), a sensing device (such as a fingerprint sensor, a fingerprint reader, an X-ray sensor), a semiconductor devices or lighting devices, etc., the present invention does not make any limitation here.

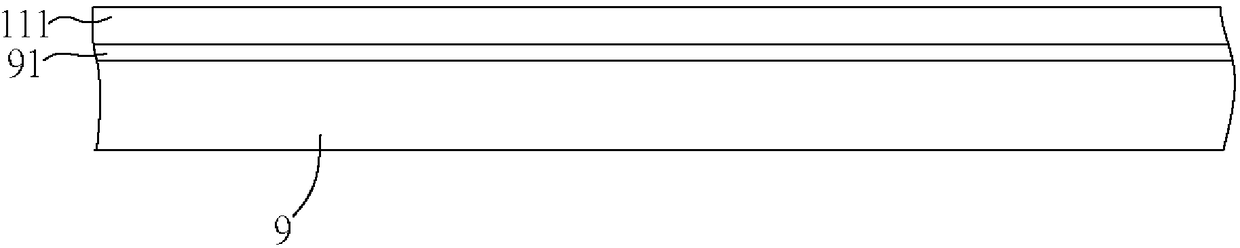

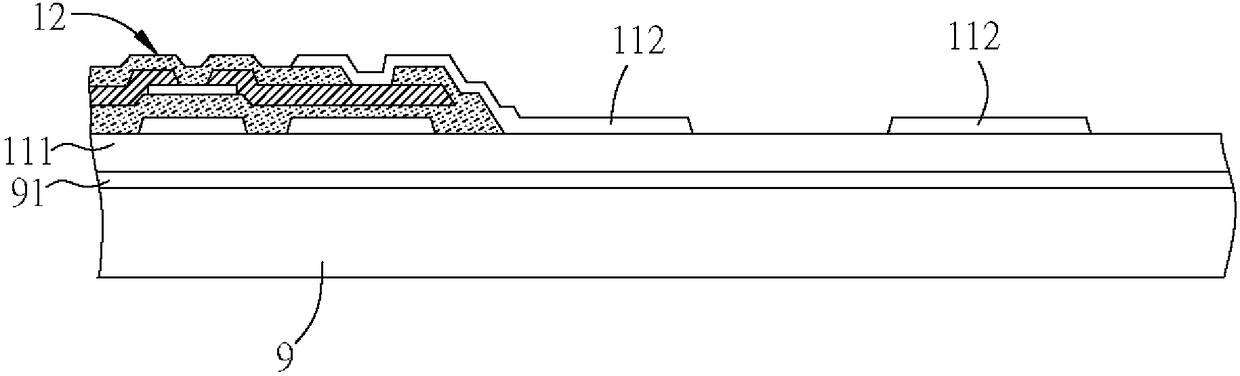

[0029] Such as figure 1 As shown, the manufacturing method of the electronic device 1 includes the following steps: forming a flexible substrate (Flexible Substrate) on a rigid carrier (step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com