Top cover assembly and secondary battery

A technology of secondary battery and top cover, applied in the direction of secondary battery, secondary battery manufacturing, battery cover/end cover, etc., can solve the problem of affecting the assembly efficiency of secondary battery, complicated assembly process, and separation of pole and top cover. connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

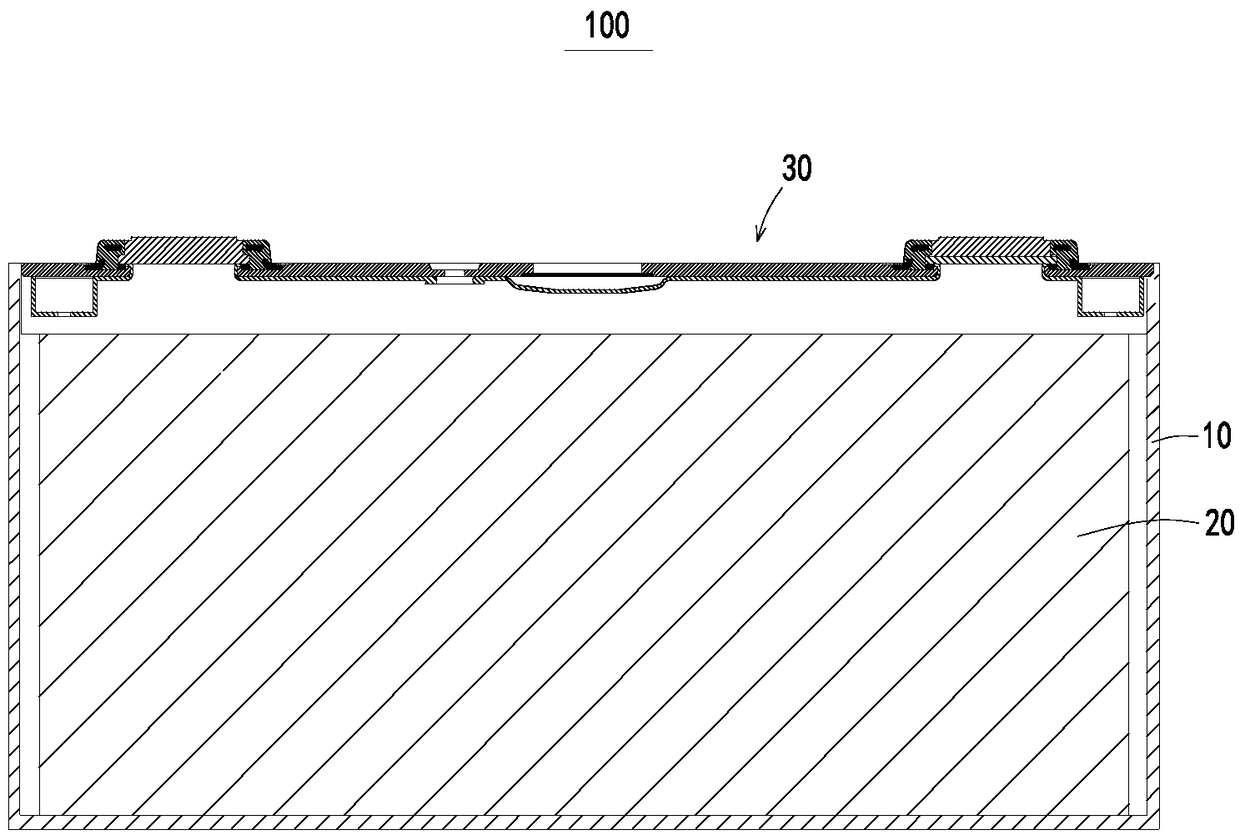

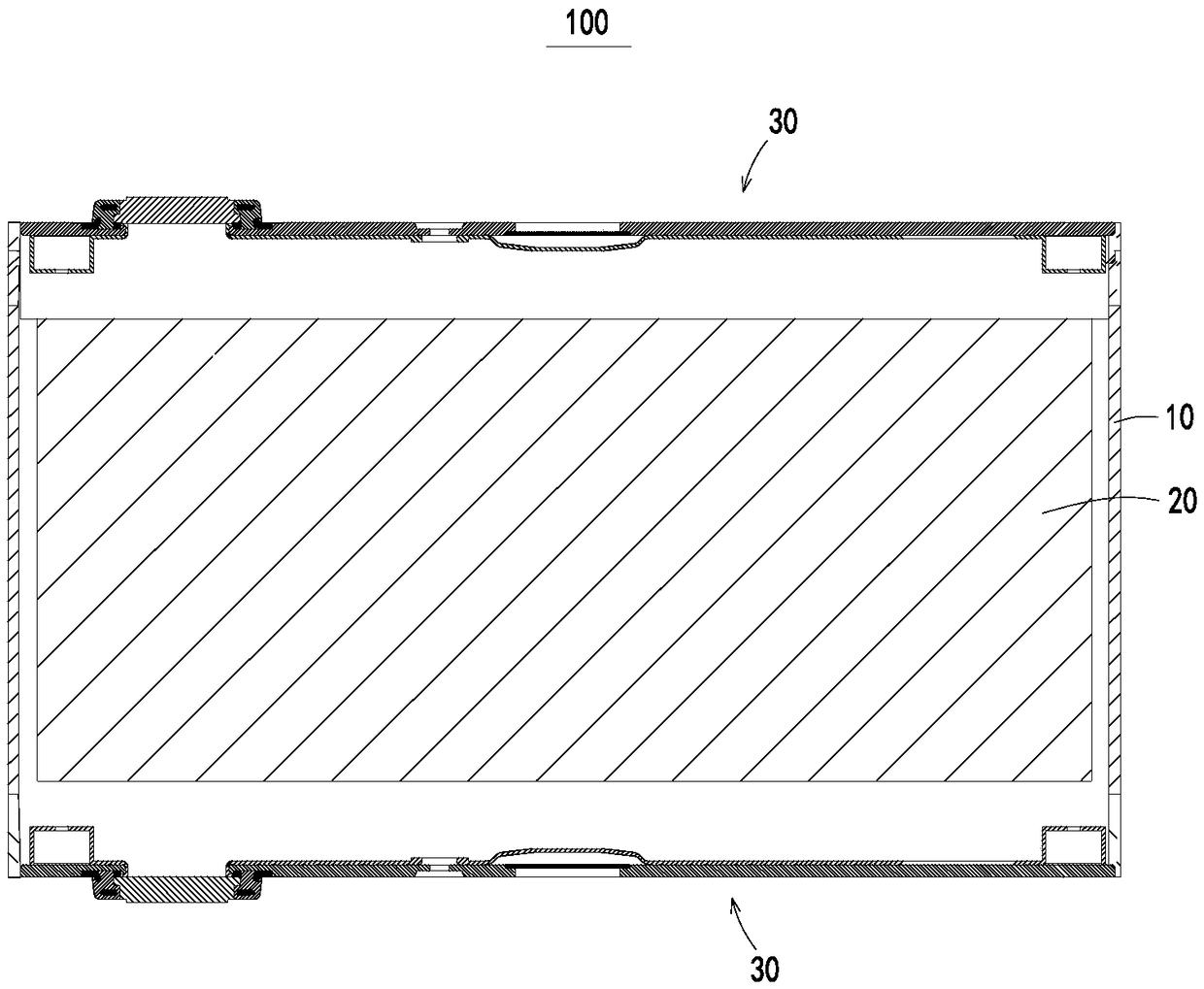

[0053] In order to better understand the present invention, the following combination Figure 3 to Figure 9 The secondary battery 100 and the top cover assembly 30 of the embodiment of the present invention will be described in detail.

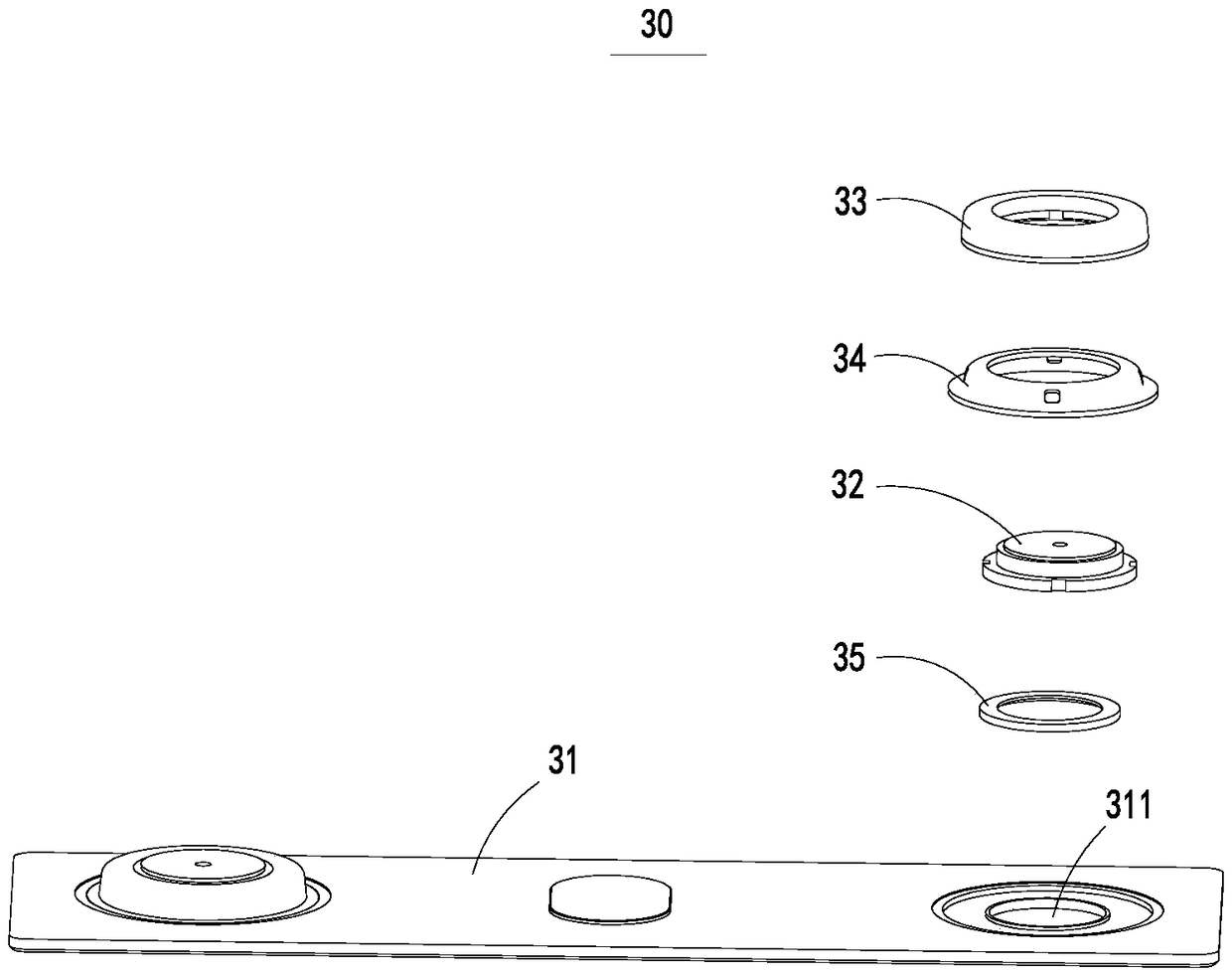

[0054] see Figure 6 and Figure 7 As shown, the first fixing member 33 of this embodiment is provided with an embedding portion 331 , and the main body portion 341 of the second fixing member 34 is provided with an embedding hole 342 . A part of the first fixing member 33 is located in the embedding hole 342 to form the embedding portion 331 . The first fixing part 33 can effectively improve the connection strength between the first fixing part 33 and the second fixing part 34 through the embedded part 331 and the embedding hole 342 included in the second fixing part 34. The connection between the fixing part 33 and the second fixing part 34 is not easy to be separated or loosened, which further ensures the stability of the connection betw...

no. 2 example

[0068] In the first embodiment, the structure of the top cover assembly 30 has been described. In this embodiment, differences from the first embodiment are mainly described, and the same structure will not be repeatedly described in this embodiment.

[0069] see Figure 10 As shown, the first fixing member 33 of the embodiment of the present invention is provided with an embedding hole 342 , and the main body portion 341 included in the second fixing member 34 is provided with an embedding portion 331 . The embedding hole 342 provided on the first fixing member 33 may be a through hole or a blind hole. Preferably, the embedding hole 342 provided on the first fixing member 33 is a blind hole. A part of the second fixing member 34 is located in the embedding hole 342 to form the embedding portion 331 . The second fixing part 34 can effectively improve the connection strength between the first fixing part 33 and the second fixing part 34 through the embedded part 331 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com