Socket equipped with shielding layer for internal grounding

A technology of shielding grounding and shielding layer is applied in the field of electric vehicle charging sockets, which can solve the problems of poor operation and assembly, complex protective structure, and difficulty in achieving IP67 protection, so as to reduce leakage, simple structure and good protective performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

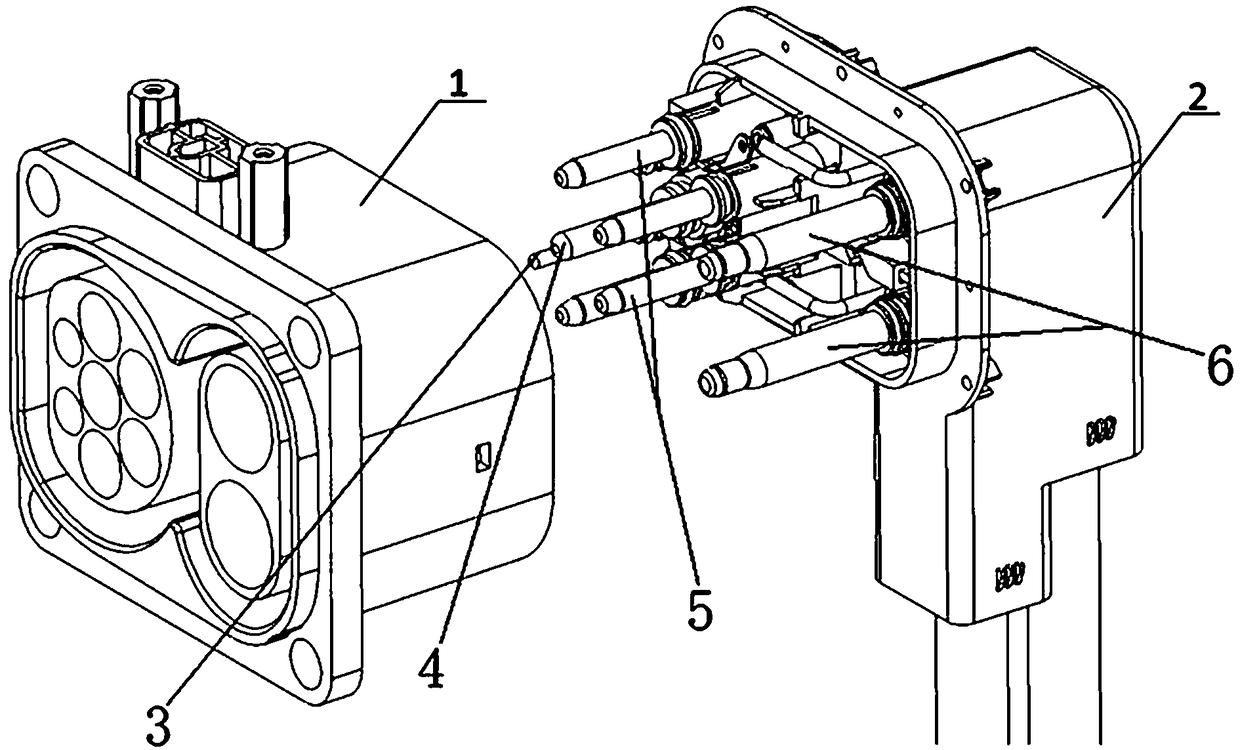

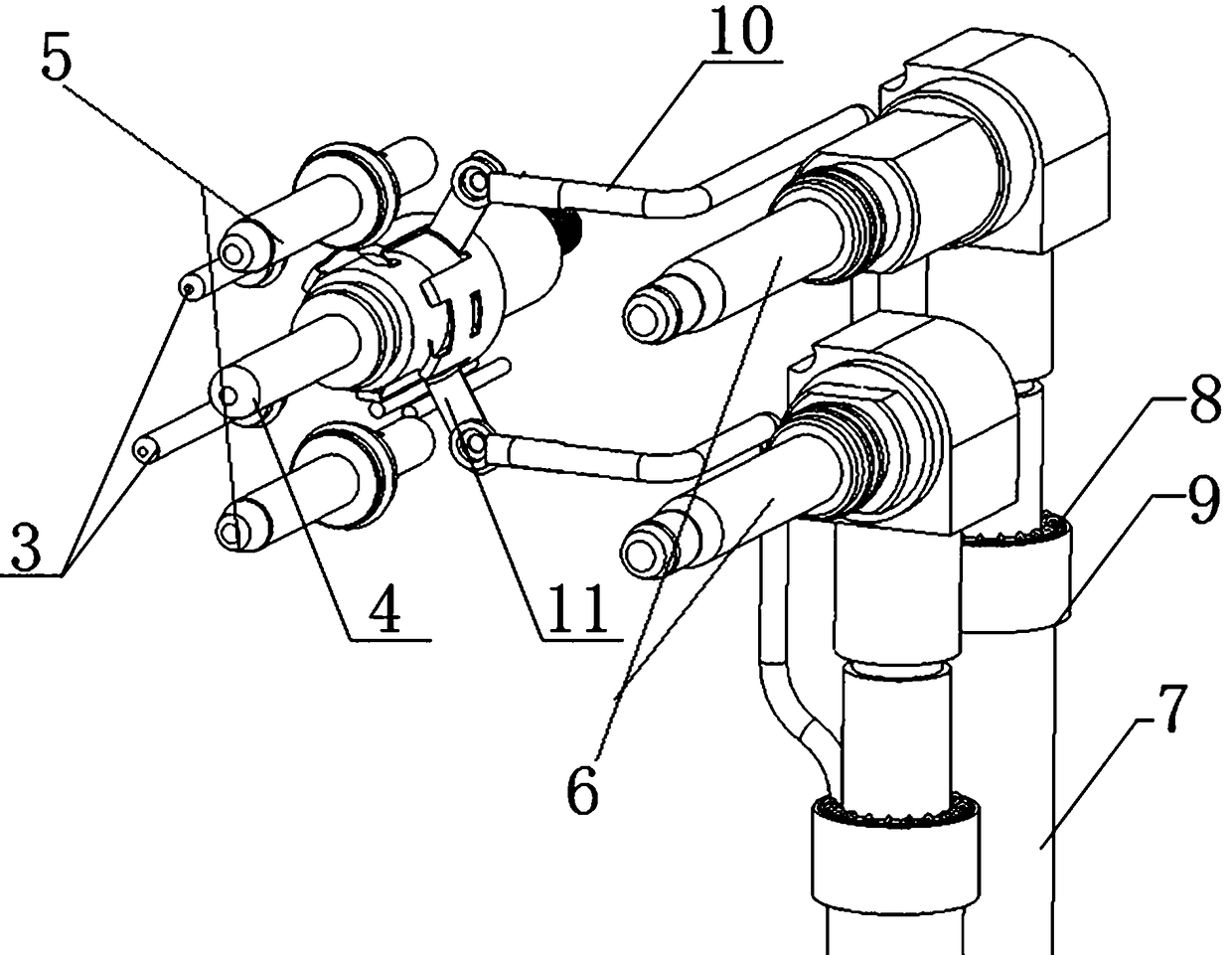

[0022] Refer to attached figure 1 , 2 , 3, 6, a socket provided with the internal grounding of the shielding layer includes a front housing 1, a rear housing 2, a terminal module 1, a terminal module 2 and a shielding grounding connection module; The terminal module 1 and the terminal module 2, the front end of the rear case is provided with a corresponding front case 1, the front case 1 is provided with jacks for passing through the terminal module 1 and the terminal module 2, the terminal module 1 and the terminal module The shielding layer is grounded through the shielding ground connection module connection between the two.

[0023] The front shell 1 and the rear shell 2 are connected by bolts or buckles.

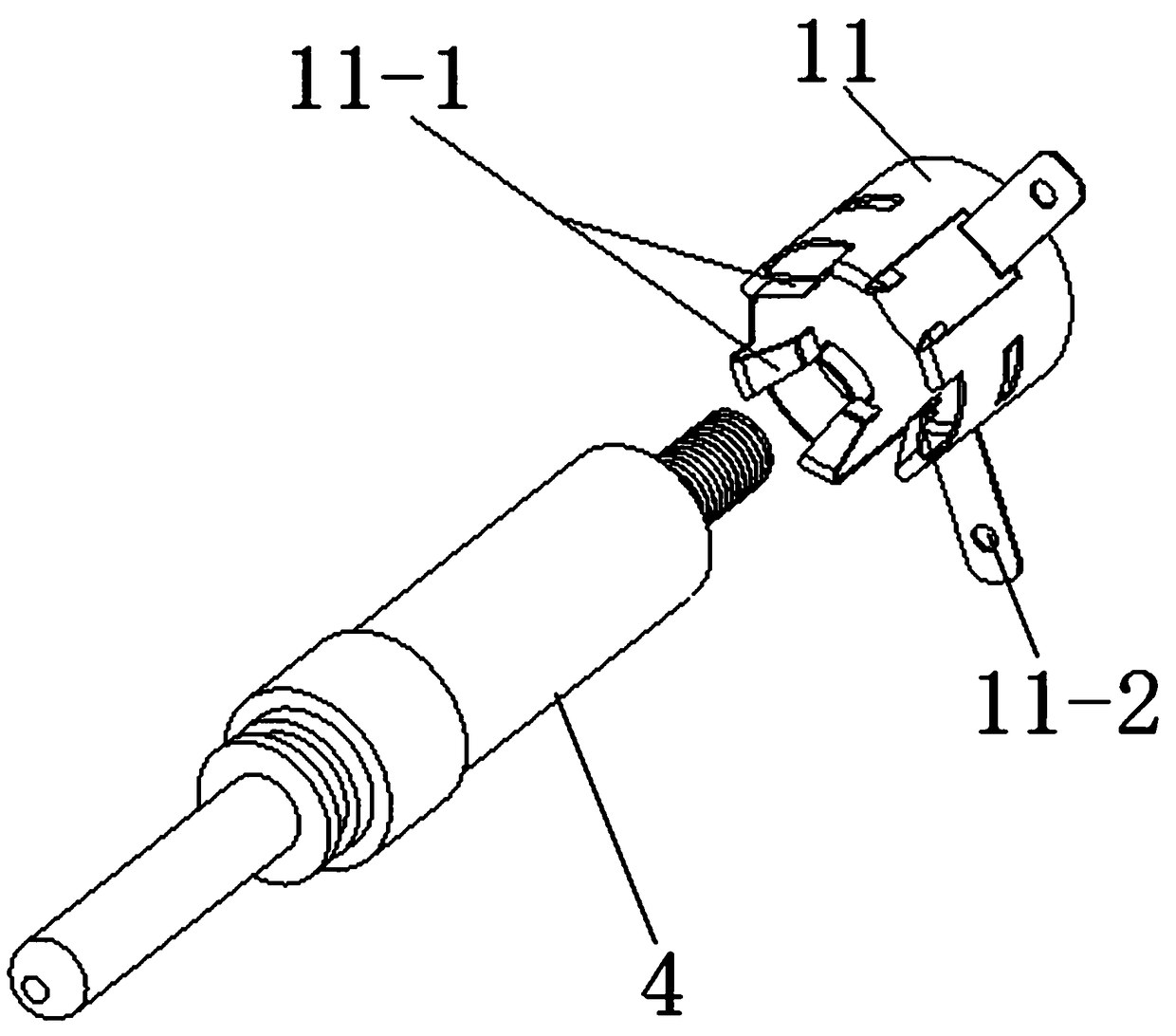

[0024] The first terminal module includes a signal terminal 3, a ground terminal 4 and an AC high-voltage terminal 5; with the ground terminal 4 as the center of a circle, a pair of signal terminals 3 are provided on one side of the ground terminal 4, and one or Two ...

Embodiment 2

[0029] Refer to attached figure 1 , 4 , 5, 6, a socket provided with internal grounding of the shielding layer includes a front housing 1, a rear housing 2, a terminal module 1, a terminal module 2 and a shielding grounding connection module; The terminal module 1 and the terminal module 2, the front end of the rear case is provided with a corresponding front case 1, the front case 1 is provided with jacks for passing through the terminal module 1 and the terminal module 2, the terminal module 1 and the terminal module The shielding layer is grounded through the shielding ground connection module connection between the two.

[0030] The front shell 1 and the rear shell 2 are connected by bolts or buckles.

[0031] The first terminal module includes a signal terminal 3, a ground terminal 4 and an AC high-voltage terminal 5; with the ground terminal 4 as the center of a circle, a pair of signal terminals 3 are provided on one side of the ground terminal 4, and one or Two pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com