Fruit picking and sorting device

A sorting device and fruit technology, applied in picking machines, grading, solid separation, etc., can solve the problems of high labor intensity, low work efficiency, tearing of branches, etc., to avoid bumping, long contact time, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

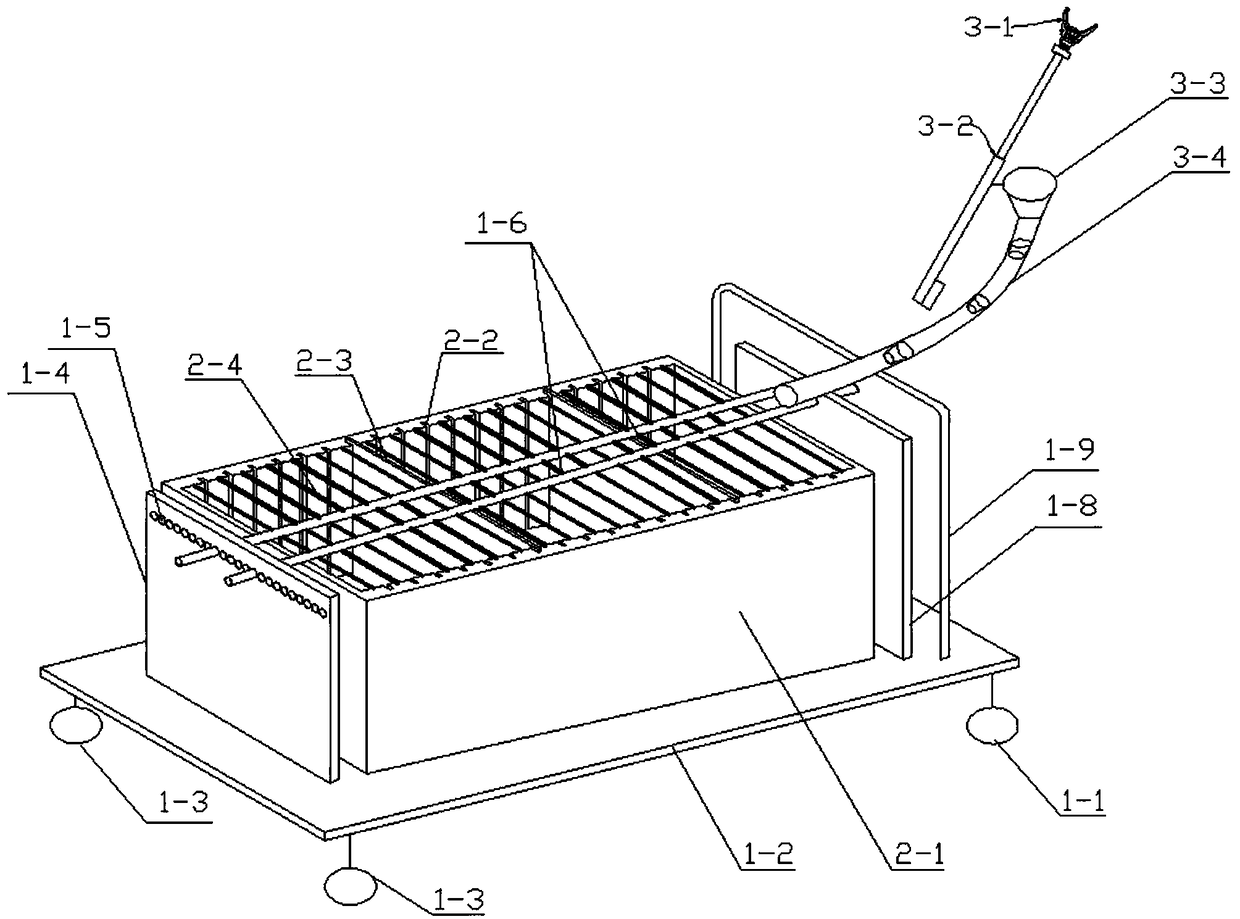

[0026] Such as figure 1 As shown, a fruit picking and sorting device includes a trolley, a picking transmission unit and a screening collection unit. The screening collection unit is placed on the trolley. The front wheel 1-1 and the rear wheel 1-3;

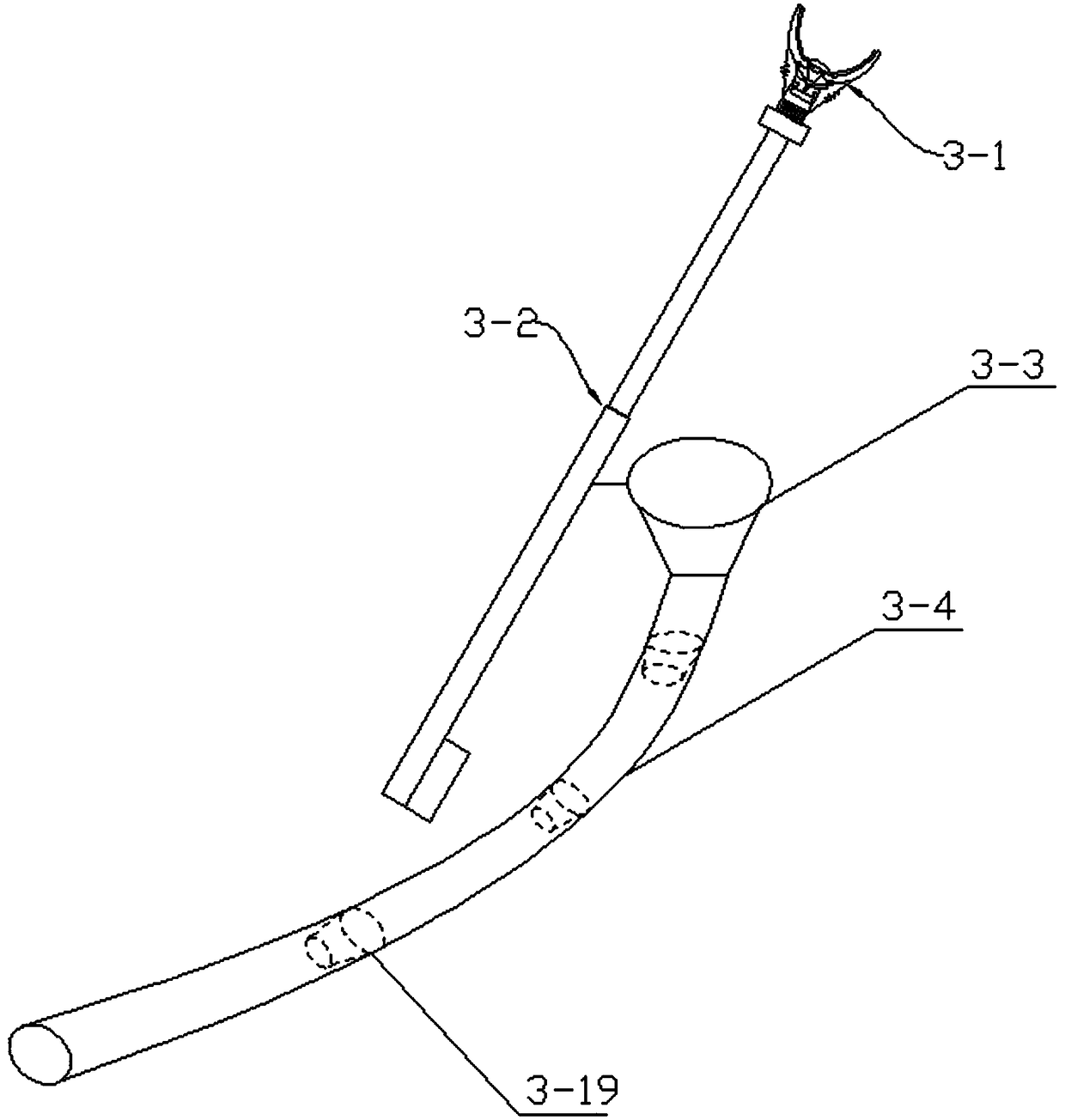

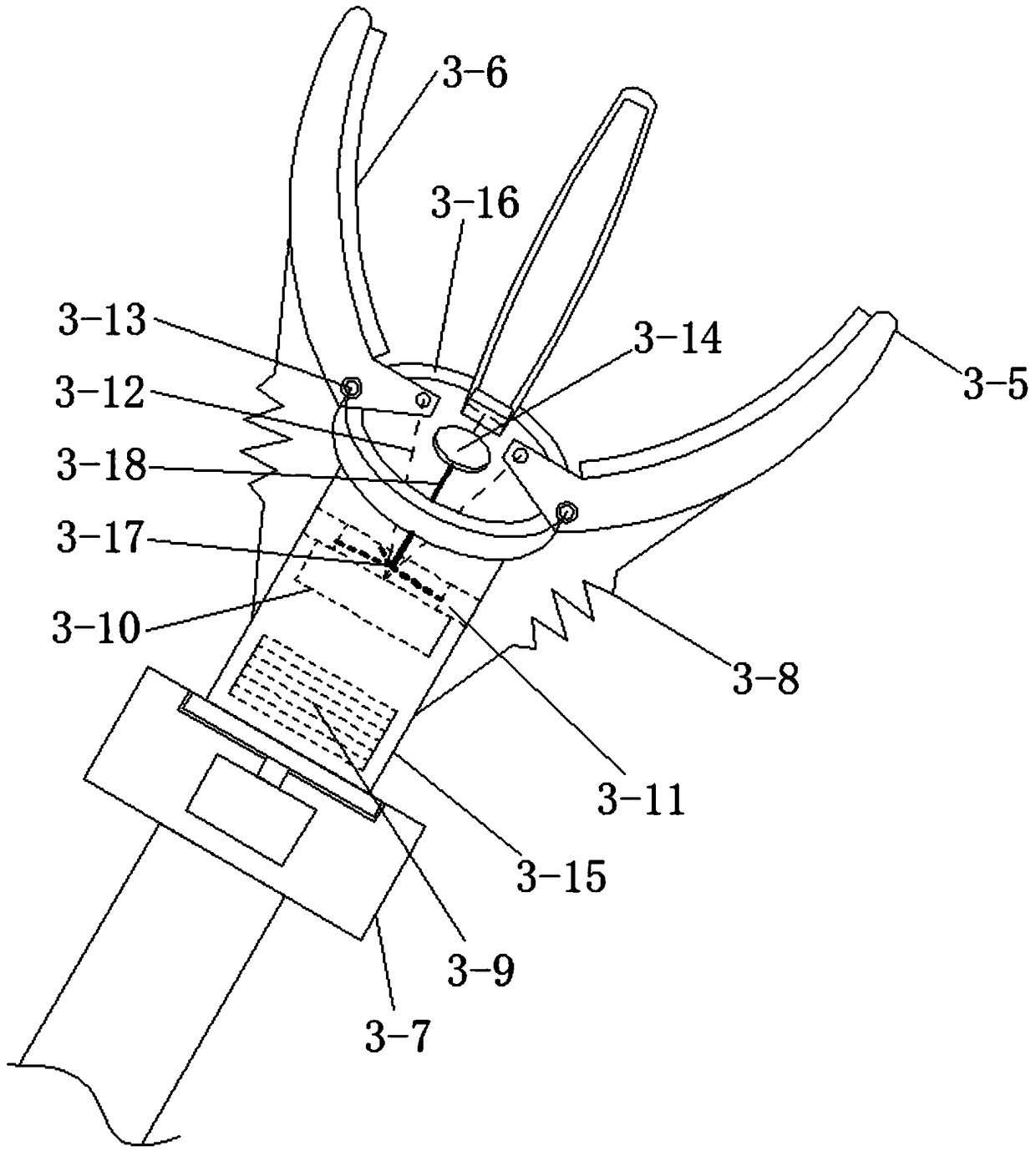

[0027] Such as figure 2 and image 3As shown, the picking transmission unit includes a picking hand 3-1, a rotating platform 3-7, a telescopic rod 3-2, a funnel into the bag 3-3 and a delivery pipe 3-4; the picking hand 3-1 includes a limit ring 3- 11. Counterweight iron block 3-10, electromagnet 3-9, hollow sleeve 3-15, assembly ring 3-16, picking claw 3-5 and distance measuring sensor 3-14; limit ring 3-11 , counterweight iron block 3-10 and electromagnet 3-9 are arranged in the inside of hollow sleeve 3-15 successively from top to bottom, and limit ring 3-11 and electromagnet 3-9 are all connected with hollow sleeve 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com