Multifunctional automatic applicator of fluorescent powder glue and control method thereof

An automatic coating and fluorescent powder technology, which is applied in coatings, devices for coating liquid on the surface, electrical components, etc., can solve the problems of uneven coating thickness, low light extraction efficiency, and low degree of production automation of wafer-level LEDs. problems, achieve the effect of changing the production operation mode, high degree of automation, and improving coating production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

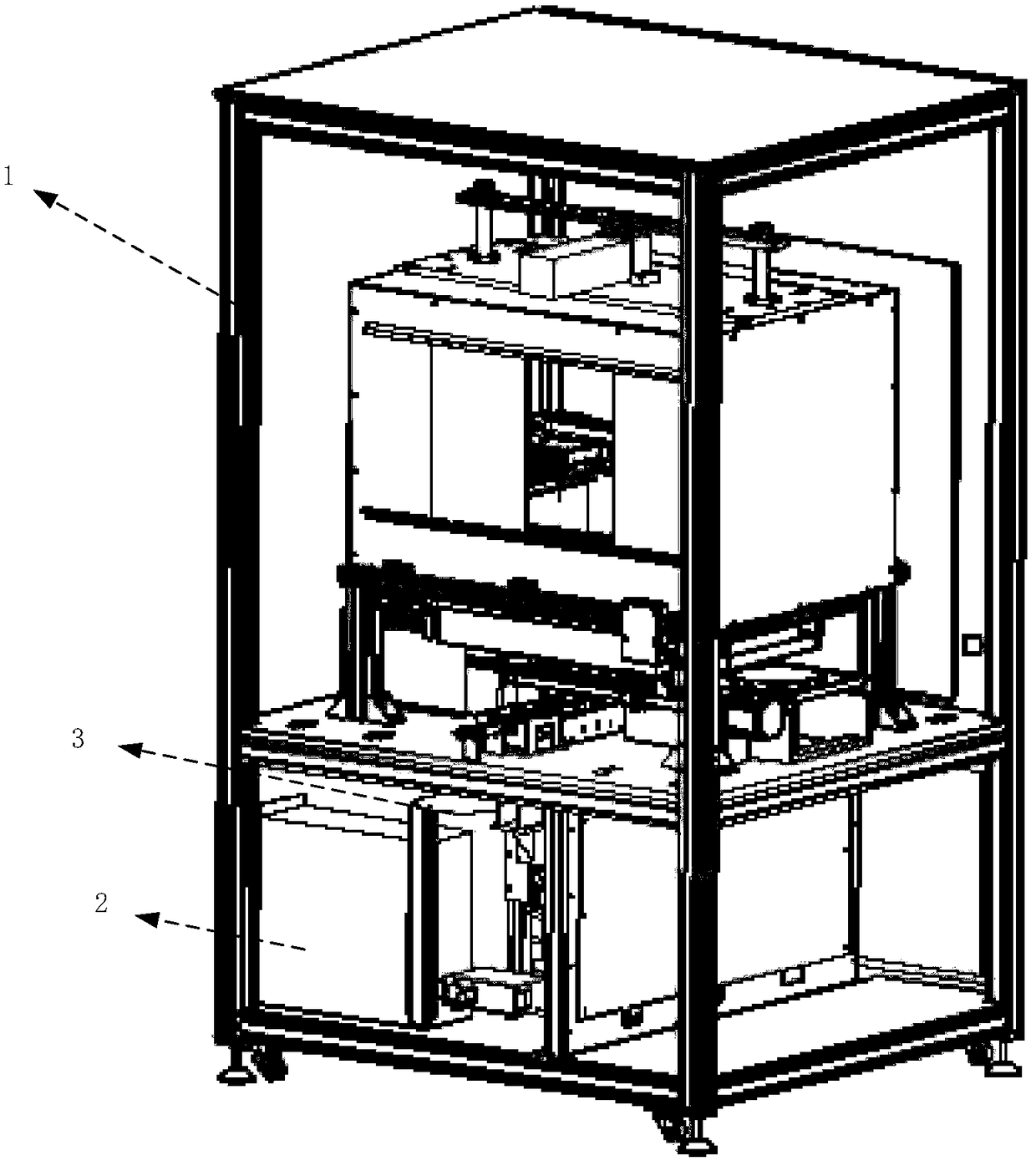

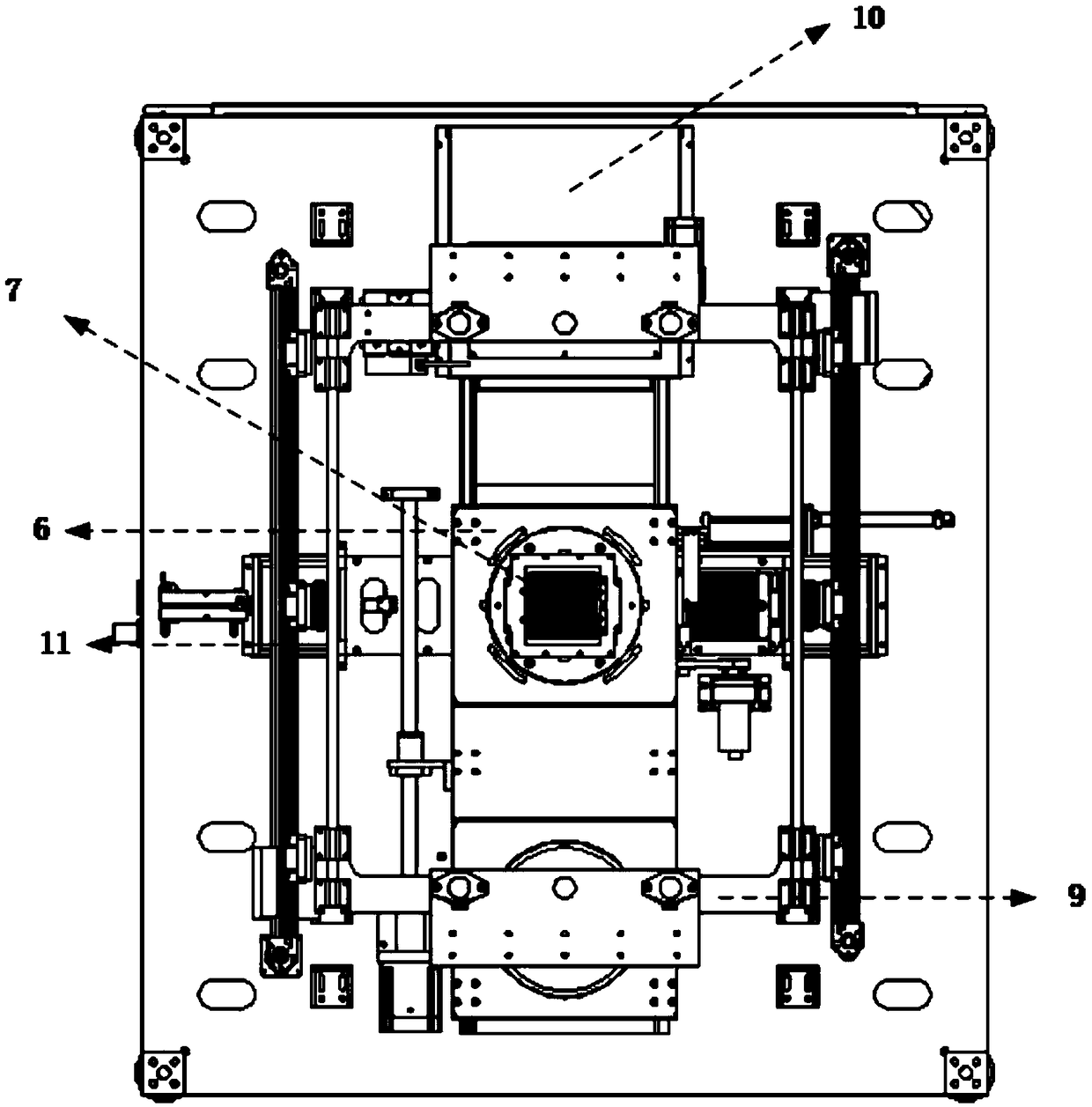

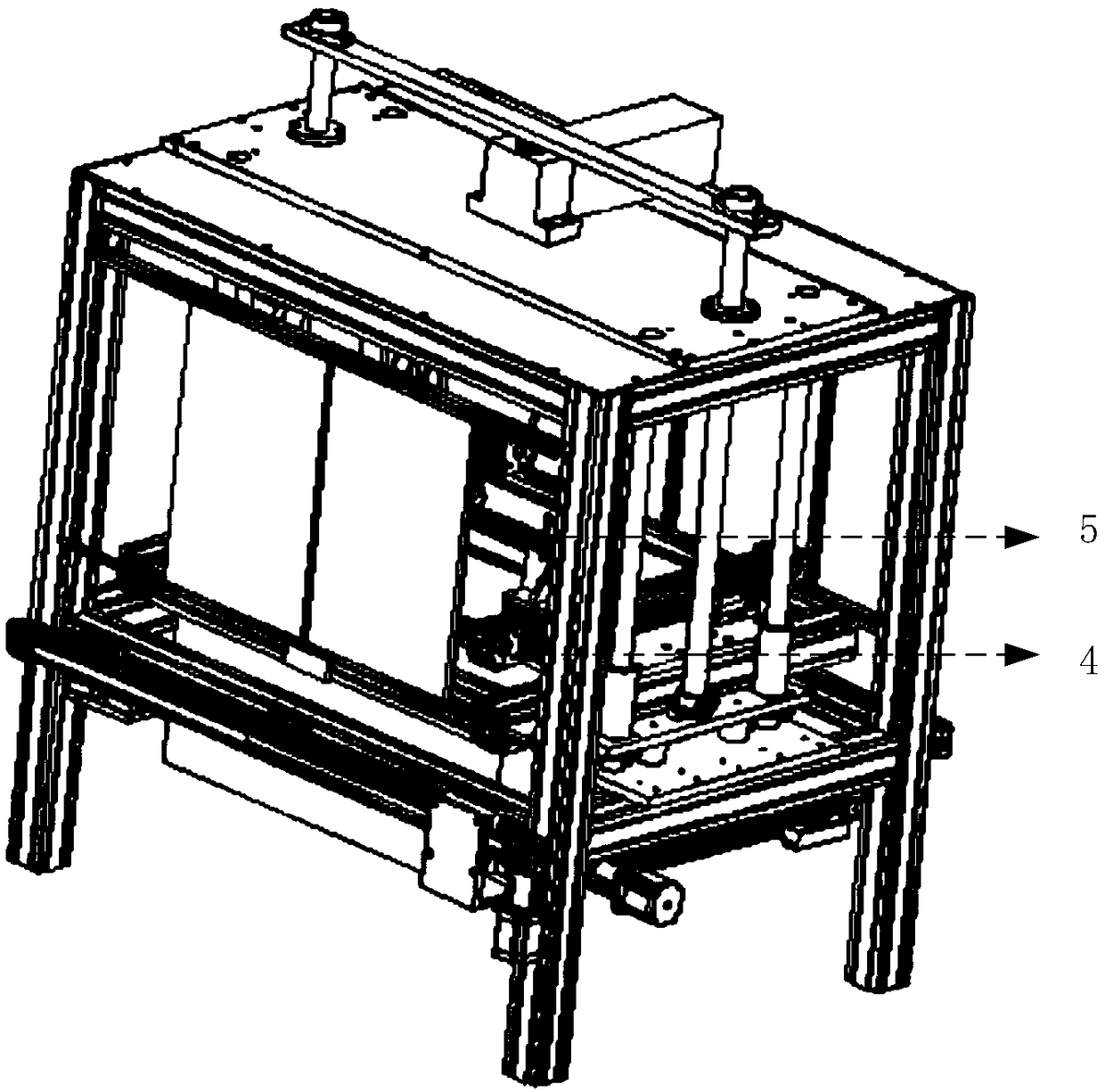

[0047] Such as figure 1 As shown, a multifunctional fluorescent powder glue automatic coating machine includes an upper computer, a frame, a lower computer structure and a sequentially connected feeding conveyor belt, coating conveyor belt and unloading conveyor belt, and the lower computer structure includes Phosphor glue feeding mechanism, WLP-LED or CSP-LED module automatic adjustable loading and unloading mechanism, phosphor glue micro-coating mechanism, phosphor glue thickness measuring system, electric heating pre-baking mechanism, automatic cleaning mechanism, Transmission mechanism and main controller.

[0048] The upper computer provides an intelligent micro-coating control system, which is responsible for acquiring and processing coating parameters, and issuing operation instructions to control the various mechanisms of the lower computer. The intelligent micro-coating control system includes a human-computer interaction interface module, a database module, an onlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com