Slide sealing machine

A case and cover technology, which is applied in microscopes, optics, instruments, etc., can solve the problems of low efficiency of sealing or dismantling, increasing the labor intensity of operators, etc., and achieve the effect of simple structure, convenient operation, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

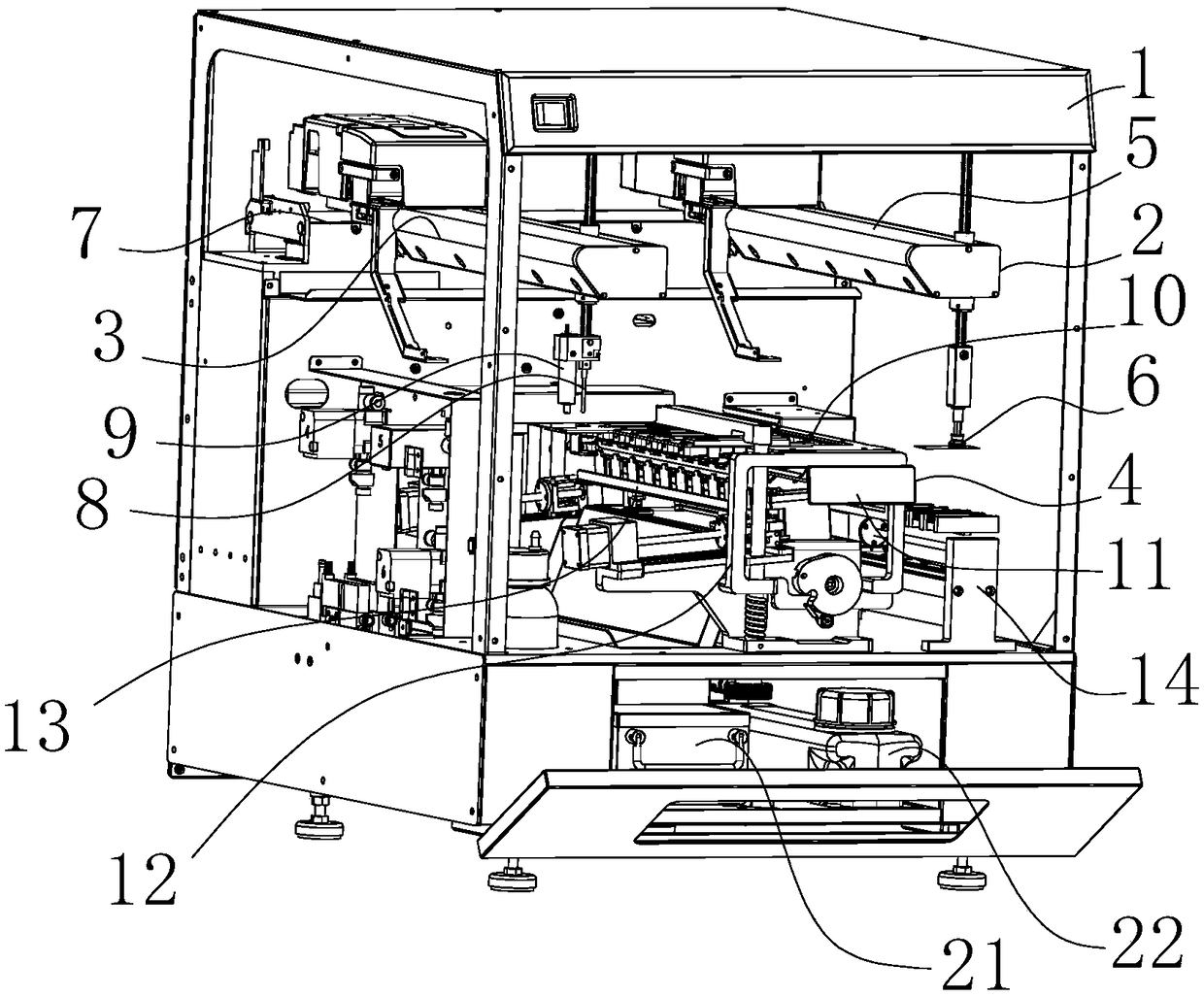

[0041] The sealing machine is mainly used for sealing slides. The sealing machine has the following functions. Put the used glass slides into the sealing machine, and the sealing machine takes the cover slips on the loaded slides and cleans the slides. After the personnel place the specimens, the sealing machine slices for sealing operation. To replace part of the hand operation, reduce the labor intensity of the operator.

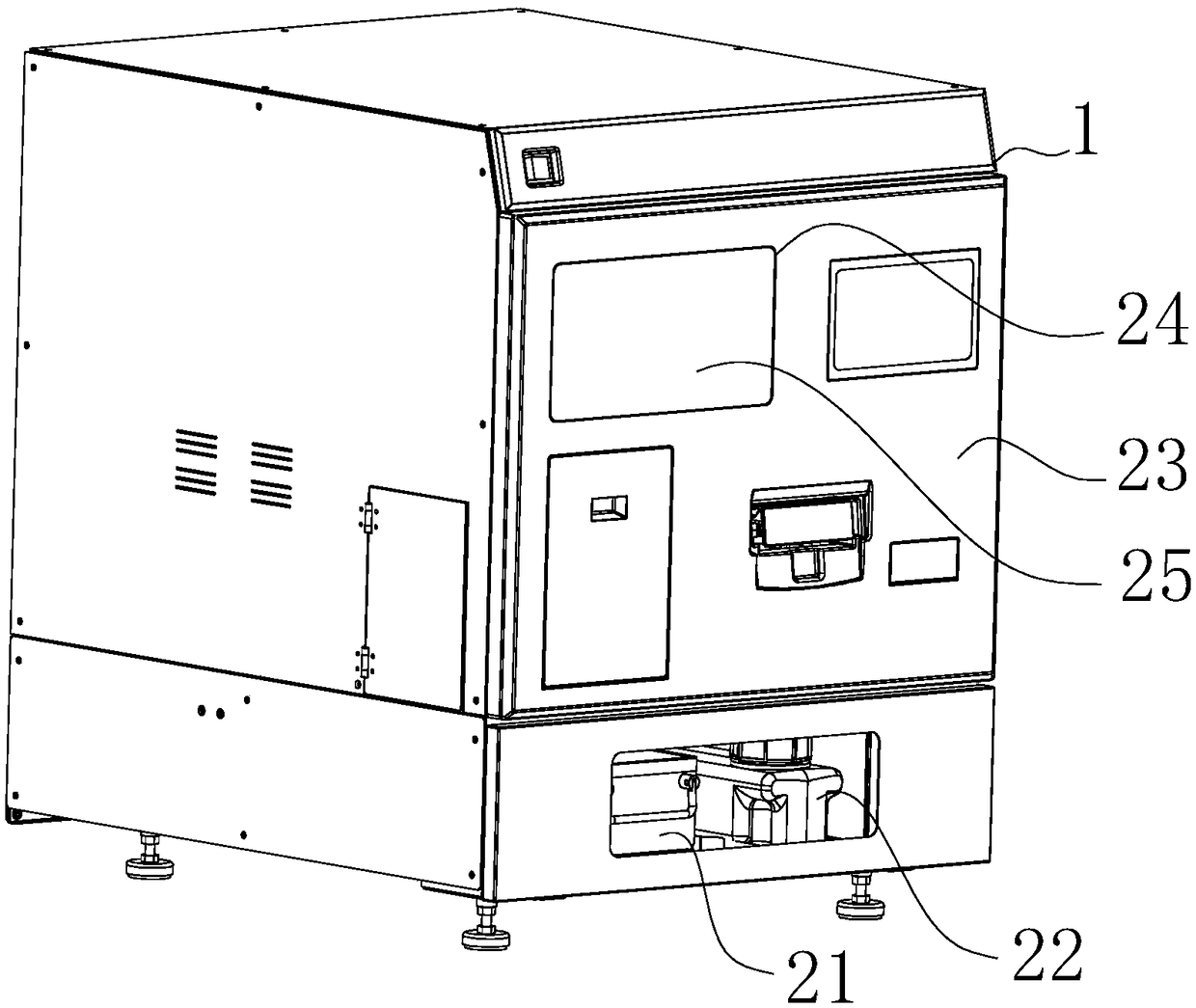

[0042] Such as figure 1 The sealing machine includes a chassis 1, and the chassis 1 includes a box body and a beam or a plate fixed in the box to install or support the corresponding structure. The beam or the plate can be fixed in the box by bolts, so as to facilitate the installation of the corresponding mechanism.

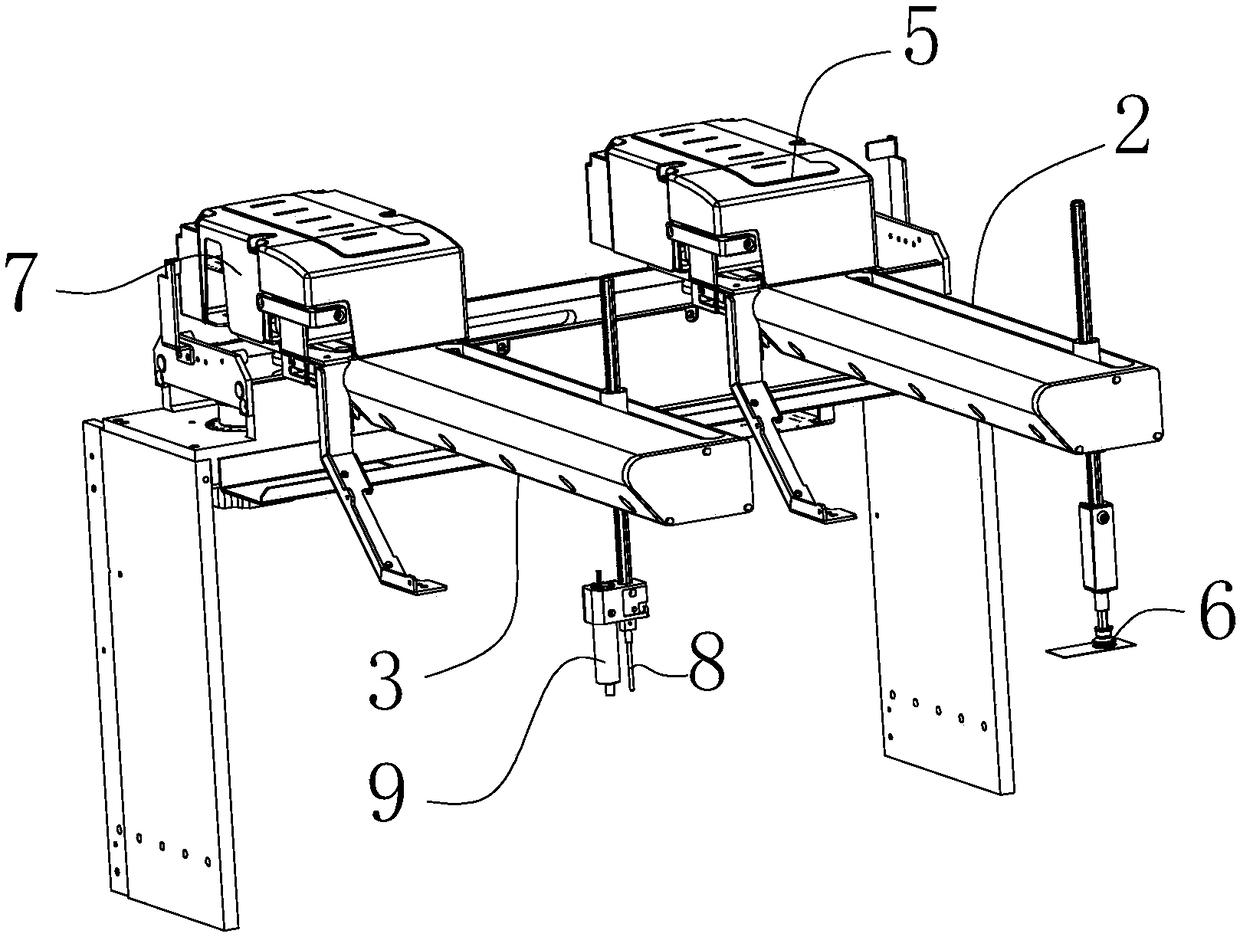

[0043] Such as figure 1 , figure 2 , a grasping mechanism 2 for grasping the cover slip, an operating mechanism 3 for operating the cover slip, and a positioning mechanism 4 for positioning the slide glass are arranged in the case 1 . ...

Embodiment 2

[0064] This embodiment introduces the gluing nozzle 9 in combination with Embodiment 1.

[0065] Such as Figure 5 , the gluing nozzle 9 is plugged with a heating body 15 for heating the gluing nozzle 9, the heating body 15 can be an electric heating body, that is, a structure that converts electric energy into heat energy is adopted, and the gluing nozzle 9 is provided with The slot for fixing the heating body 15, the slot has an opening for assembling the heating body 15, the glue nozzle 9 includes a glue outlet, and the opening is located at the end of the glue nozzle 9 away from the glue outlet, In order to avoid the heating body 15 from slipping out of the slot.

[0066] The heating body 15 can be powered by an independent power supply, or by the general power supply of the sealing machine.

[0067] The heating body 15 is mainly used for heating the gluing nozzle 9 to prevent the colloid from solidifying in the gluing nozzle 9 and causing the gluing nozzle 9 to be block...

Embodiment 3

[0069] This embodiment introduces the positioning frame 10 .

[0070] The positioning frame 10 is provided with a detector for detecting whether there is a slide on the placement frame 11, the detector includes a light source and a photosensitive assembly, and the slide glass on the placement frame 11 is located between the light source and the Between photosensitive components, the detector communicates with the controller.

[0071] There is an opaque area on the slide glass, and the slide glass is located between the light source and the photosensitive component. Whether the light emitted by the light source is blocked by the slide glass is used to detect whether there is a slide glass in the placement rack 11 .

[0072] The setting of the detector is mainly used to detect whether there is a glass slide on the placement rack 11, so as to prevent the cleaning head 8 from cleaning the placement rack 11 without slide glass, and save the amount of cleaning solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com