3D (three-dimensional) mobile phone screen glass sweeping machine and control method

A mobile phone screen and control method technology, which is applied in the direction of automatic grinding control device, workpiece feed movement control, manufacturing tools, etc., can solve the problems of insufficient fineness, uneven glass, low efficiency, etc., and achieve uniform operation, The effect of uniform sweeping and high sweeping precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

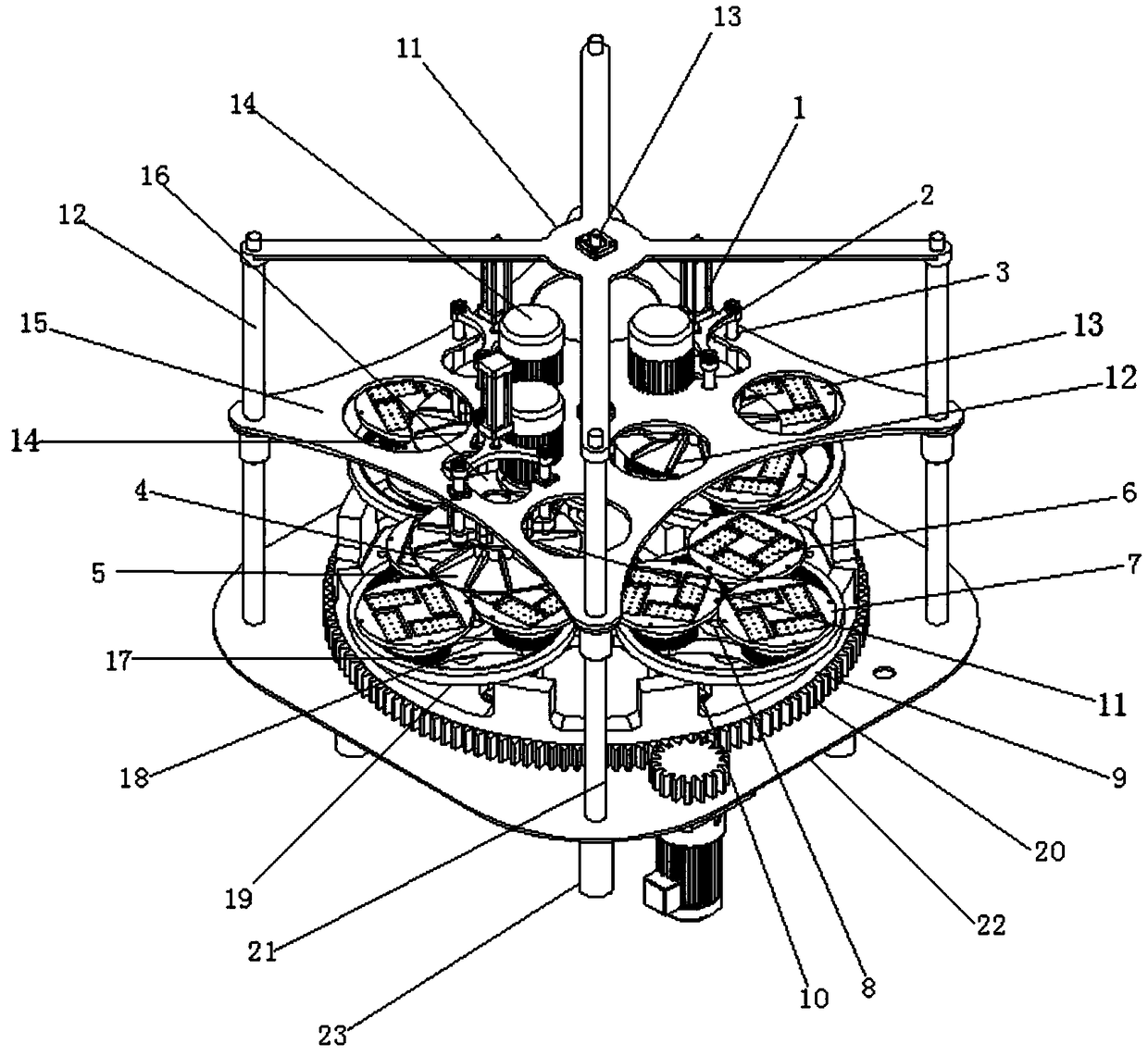

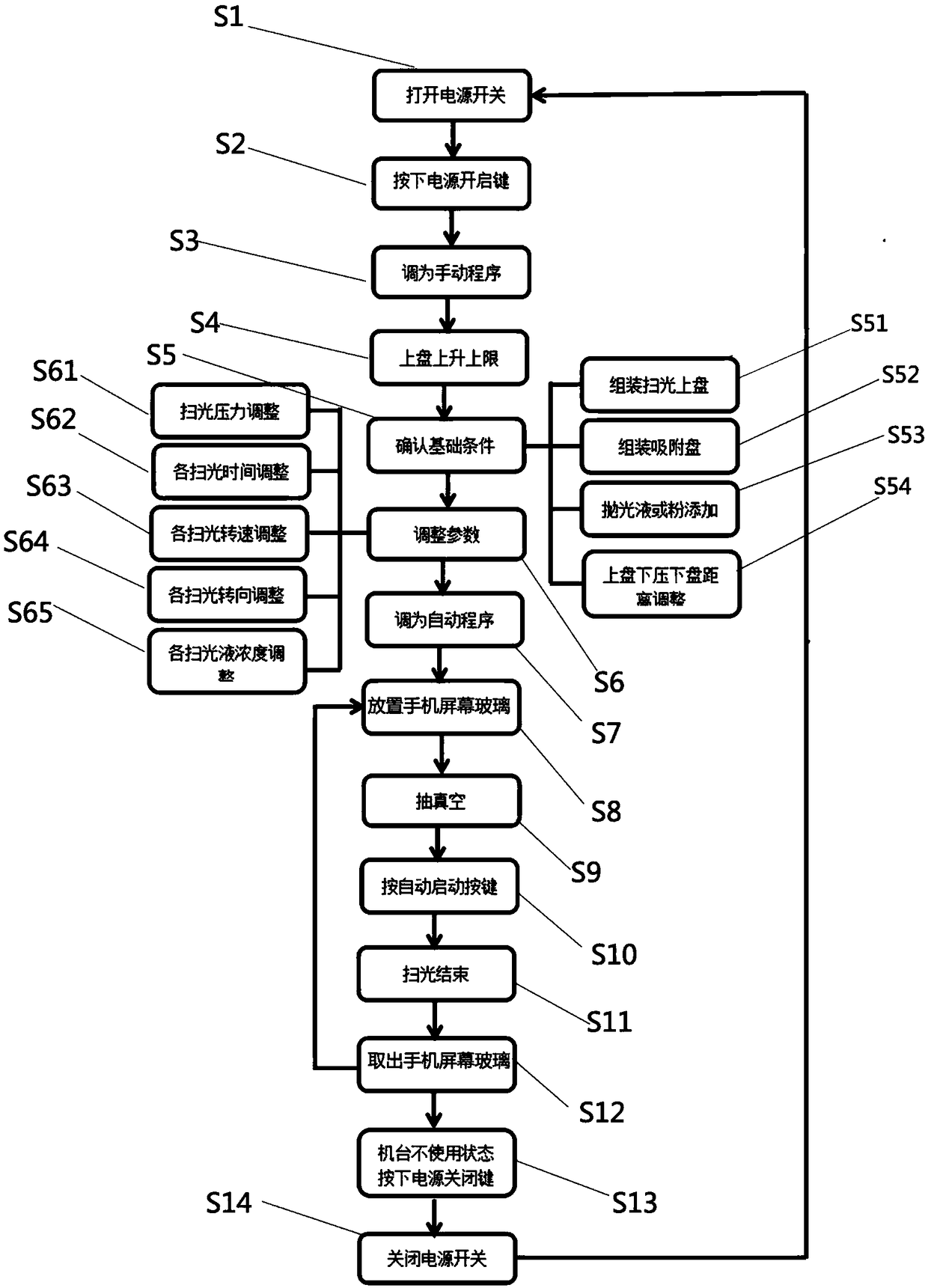

[0047] see figure 1 , the mobile phone screen 3D glass sweeper includes a frame, a vacuum system (not shown) and a drive motor, the frame is divided into an upper frame 15 and a lower frame 22, and the upper frame 15 comprises upper plate motor 14 and 4 stations, and described 4 stations comprise station 11, station 12, station 13 and station 14, in described 4 stations, wherein has a work station 11 It is a loading and unloading station; each station is provided with a sweeping disk 5 on the remaining 3 stations, and an indexing disk 20 is included on the lower disk frame 22, and the indexing disk 20 includes Indexing plate motor 8, said indexing plate 20 is provided with indexing plate main body carrier plate 9, includes 4 stations on this carrier plate 9, described 4 stations and the upper plate frame 15 The 4 stations correspond to each other; among the 4 stations on the indexing disc, one station is a loading and unloading station, and each station is provided with a rev...

Embodiment 2

[0058] see figure 1 , the difference from the above embodiment is that the ratio of the area of the scanning disc to the area of the revolving disc in the present invention is 6 to 9.5:10, preferably the ratio of the area of the scanning disc to the area of the revolving disc is 9:10, so It solves the current situation that the glass grinding amount of the mobile phone screen is inconsistent, and mainly reflects the uniformity of the online speed for each part of the revolution disk 19 and the rotation disk 7.

[0059] The operation time, operation speed, production modulus, height value of the optical disc 5 and the air pressure (current or weight) system of the optical disc 5 to the revolution disc 19 of the present invention are monitored in real time to ensure process stability.

[0060] In the present invention, the revolving disk 19 of each station is forward, reverse, self-rotating and revolution speed, the rotation speed of the scanning disc 5, and the processi...

Embodiment 3

[0062] see figure 1 , the difference from the above-mentioned embodiment is that the upper plate main frame 15 is provided with an upper plate main support frame 11; 13 is arranged on the center of the support frame 11. Four corner support rods 12 of the main body of the upper plate are also arranged on the four sides of the main body support frame 11 of the upper plate, so that the frame 15 of the upper plate is more stable.

[0063] The lower frame 22 is provided with a lower frame 21; A complete machine support rod 23 is provided under the lower disk frame 22, and the complete machine support rod 23 is used to support the entire sweeping machine equipment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap