Manufacturing method of floor covering material using bottom ash

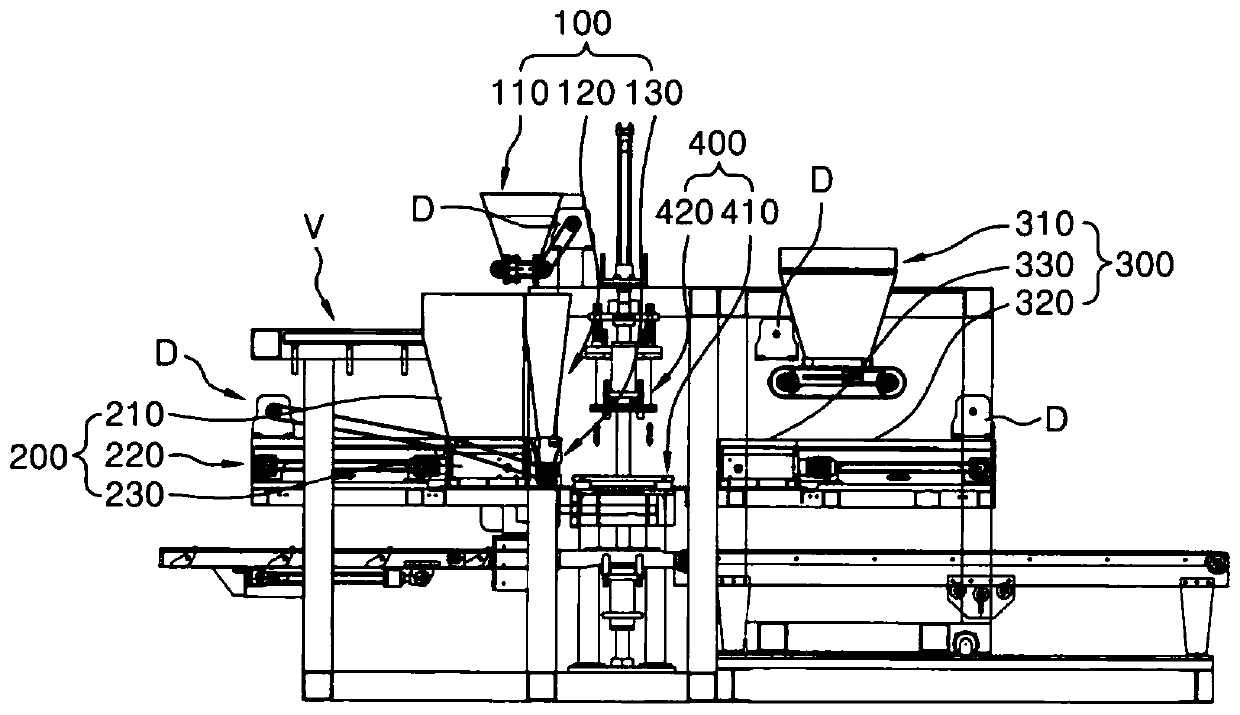

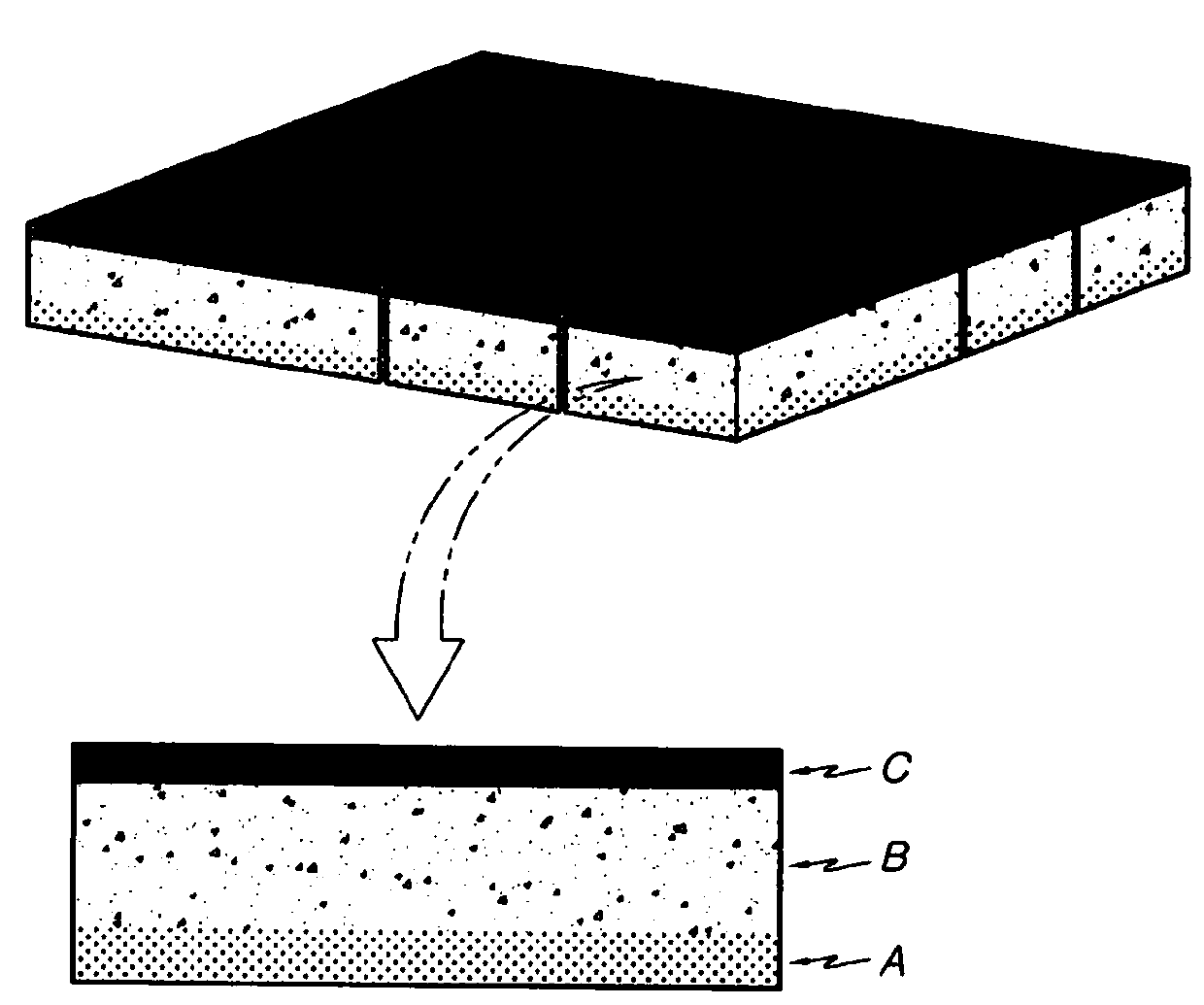

A manufacturing method and technology of paving materials, which are applied to paving surfaces, manufacturing tools, chemical instruments and methods paved with prefabricated blocks, etc., can solve the problems of reduced water permeability, inability to bear loads, weak durability, etc., and achieve both Compressive strength and flexural strength, maintaining water permeability, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

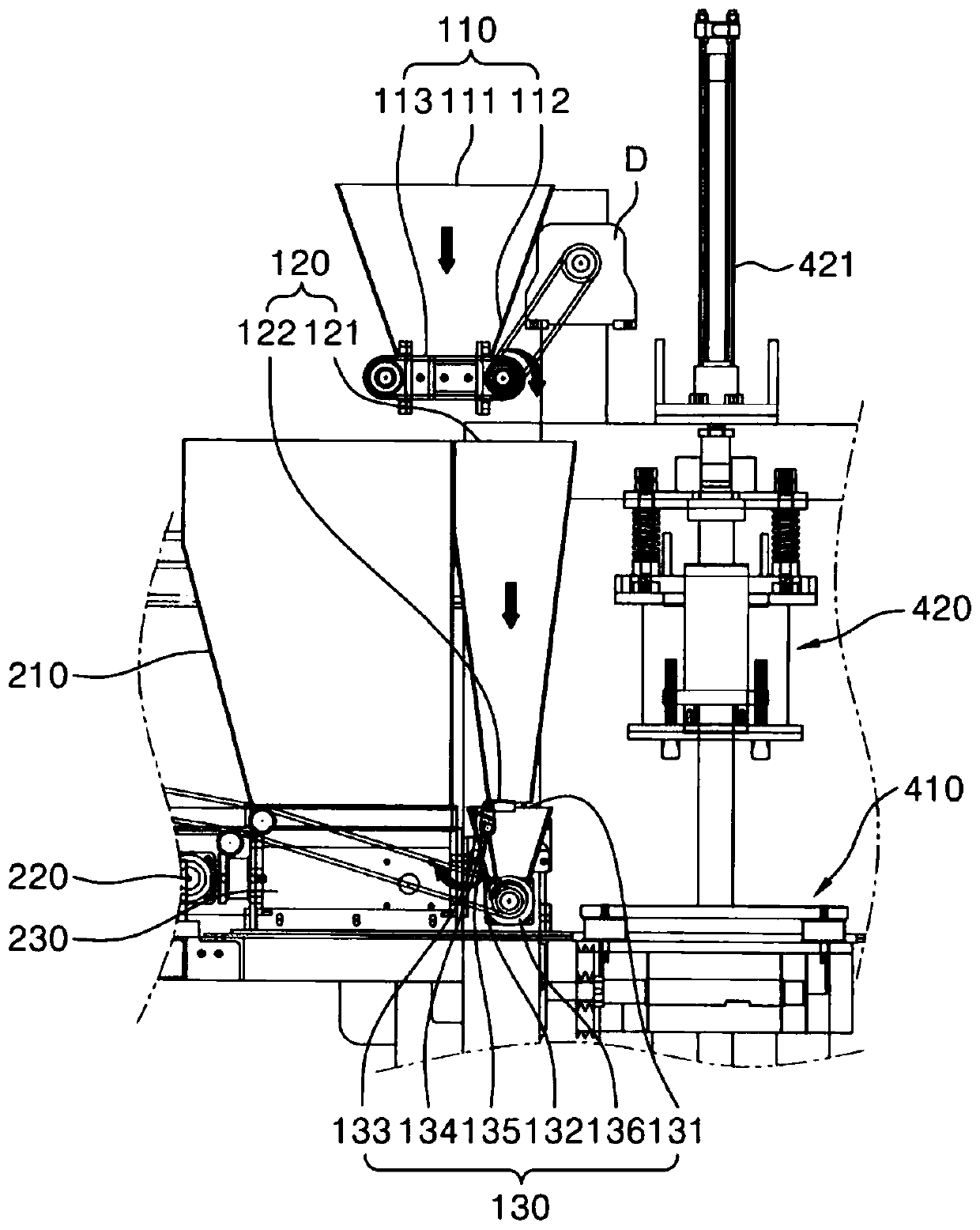

Method used

Image

Examples

Embodiment Construction

[0046] Advantages and features of embodiments of the present invention, and methods for realizing them can be clarified with reference to the drawings and embodiments described in detail later. However, the present invention is not limited to the embodiments disclosed below, and can be realized in various forms different from each other, but this embodiment is provided to make the disclosure of the present invention complete and to fully inform those skilled in the art of the scope of the invention. It is defined only by the scope of the claims. Throughout the specification, the same reference numerals refer to the same constituent elements.

[0047] In describing the embodiments of the present invention, if it is judged that the detailed description of known functions or configurations may unnecessarily obscure the gist of the present invention, the detailed description will be omitted. In addition, the terms described later are defined in consideration of the functions in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com