Full-automatic labeling machine

A labeling machine, fully automatic technology, applied in the directions of labeling machines, labels, conveyor objects, etc., can solve the problems of low work efficiency, low precision, low degree of automation, etc., to improve work efficiency, low equipment cost, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

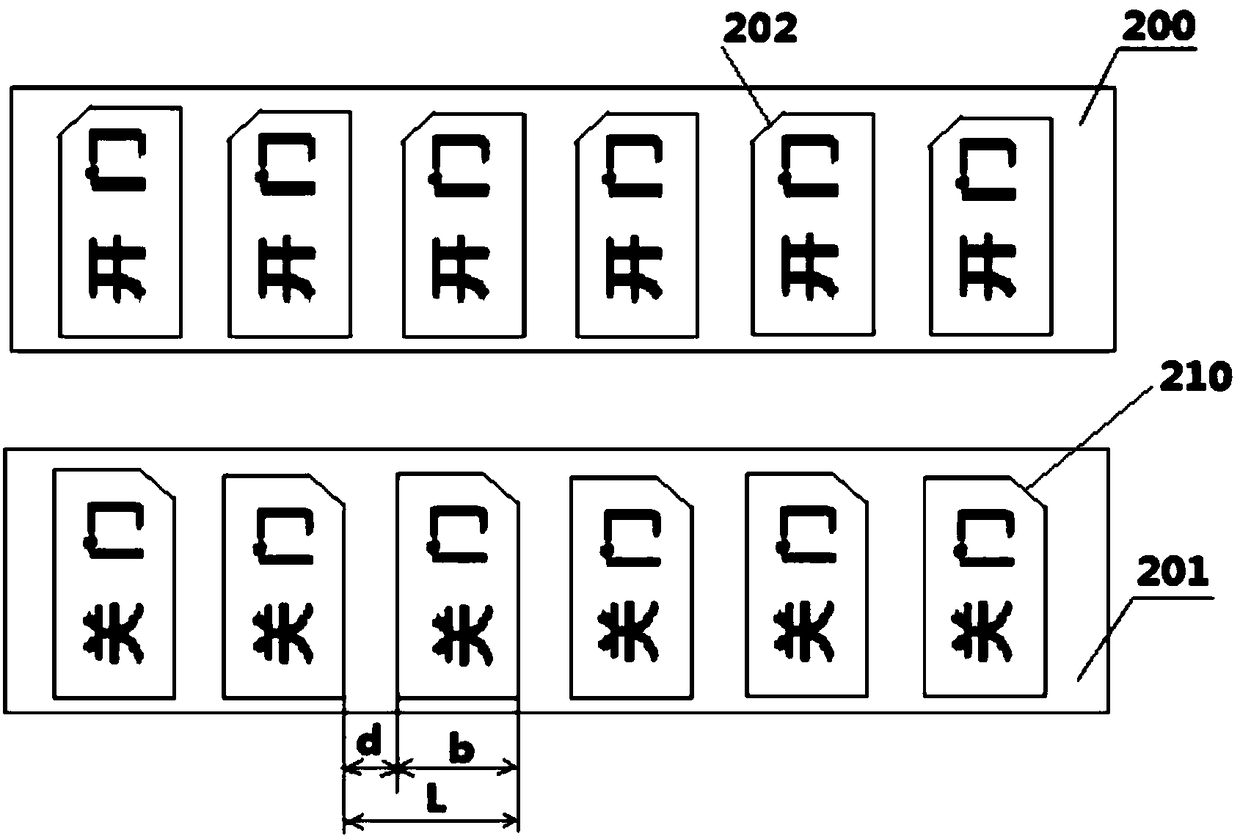

[0038] Such as figure 1 , is the supporting "opening" and "closing" label with positioning function of the present invention, including a self-adhesive roll label (installed on the material tray assembly 33) as a carrier; the inner diameter of the roll label roll is 76mm, and the outer diameter is ≤280mm , the door opening label 200 or the door closing label 201 are respectively evenly distributed on the rolled glassine backing paper; the upper left chamfer of the door opening label 200 is set as the door opening positioning mark 202, and the upper right chamfering corner of the door closing label 201 is set as the door closing positioning mark 210; Each working label of cylinder label delivery meets a consistent working step distance L=d+b; L represents the working step distance; d represents the distance between adjacent labels, b represents the width of each label; the label width b is 1mm-10mm, the label The length is 2mm-20mm; the distance d between adjacent labels is 3-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com