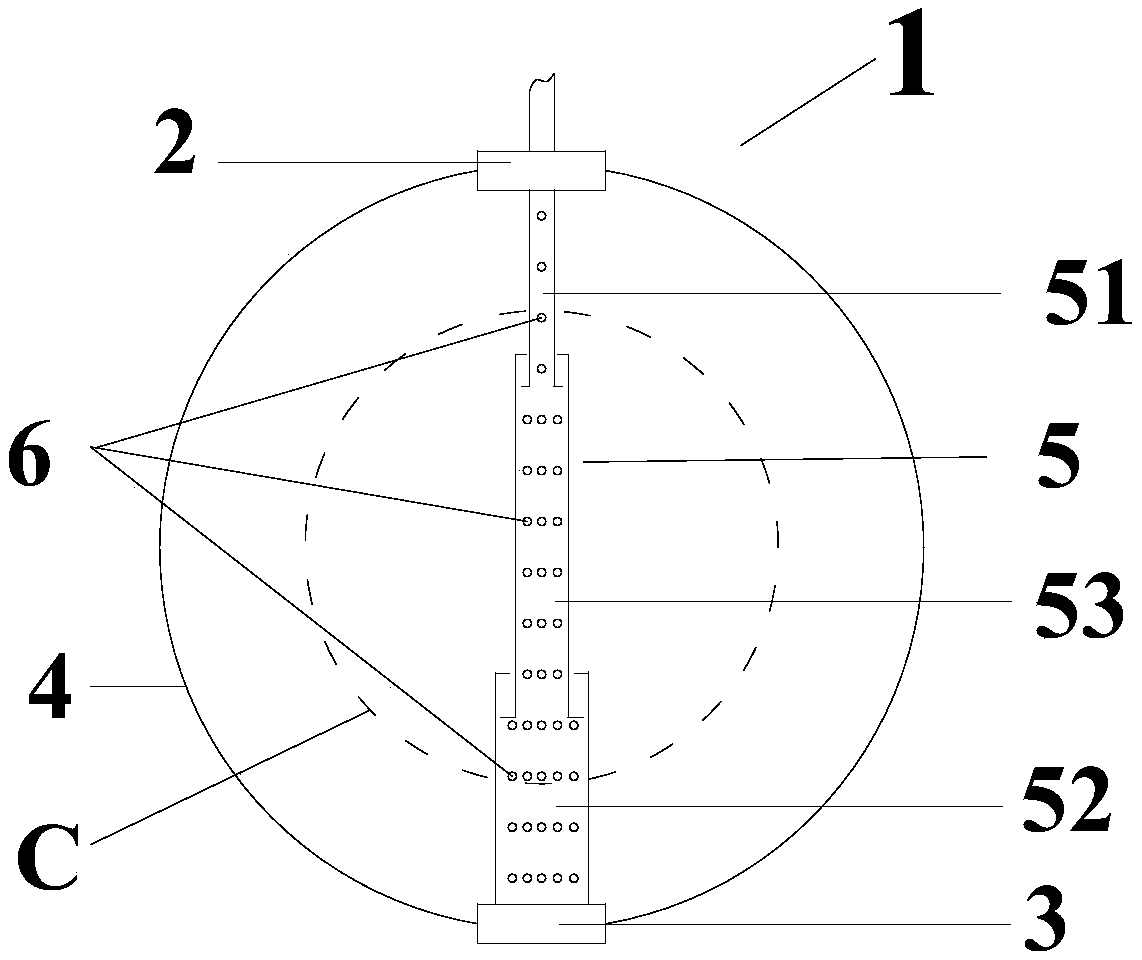

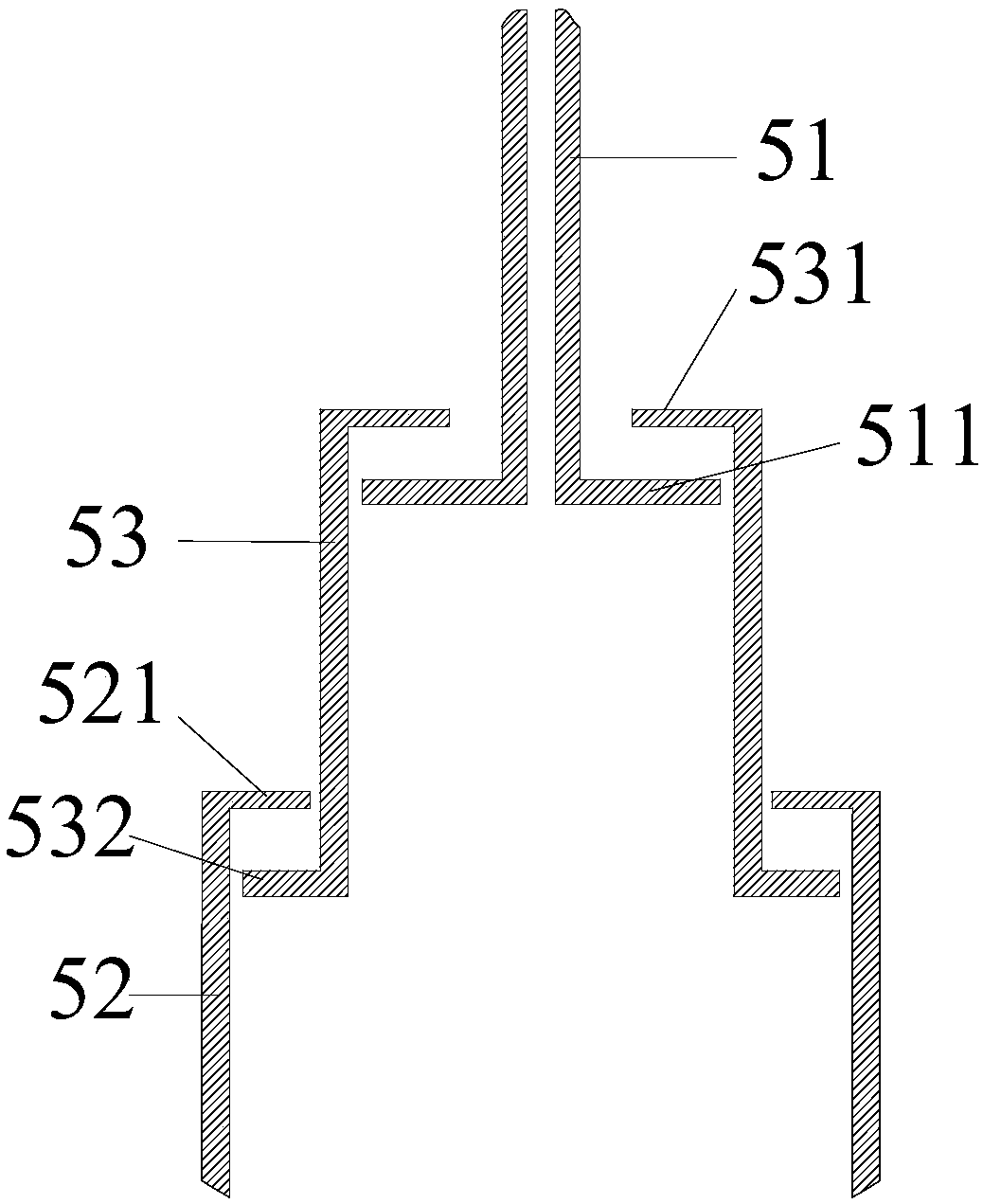

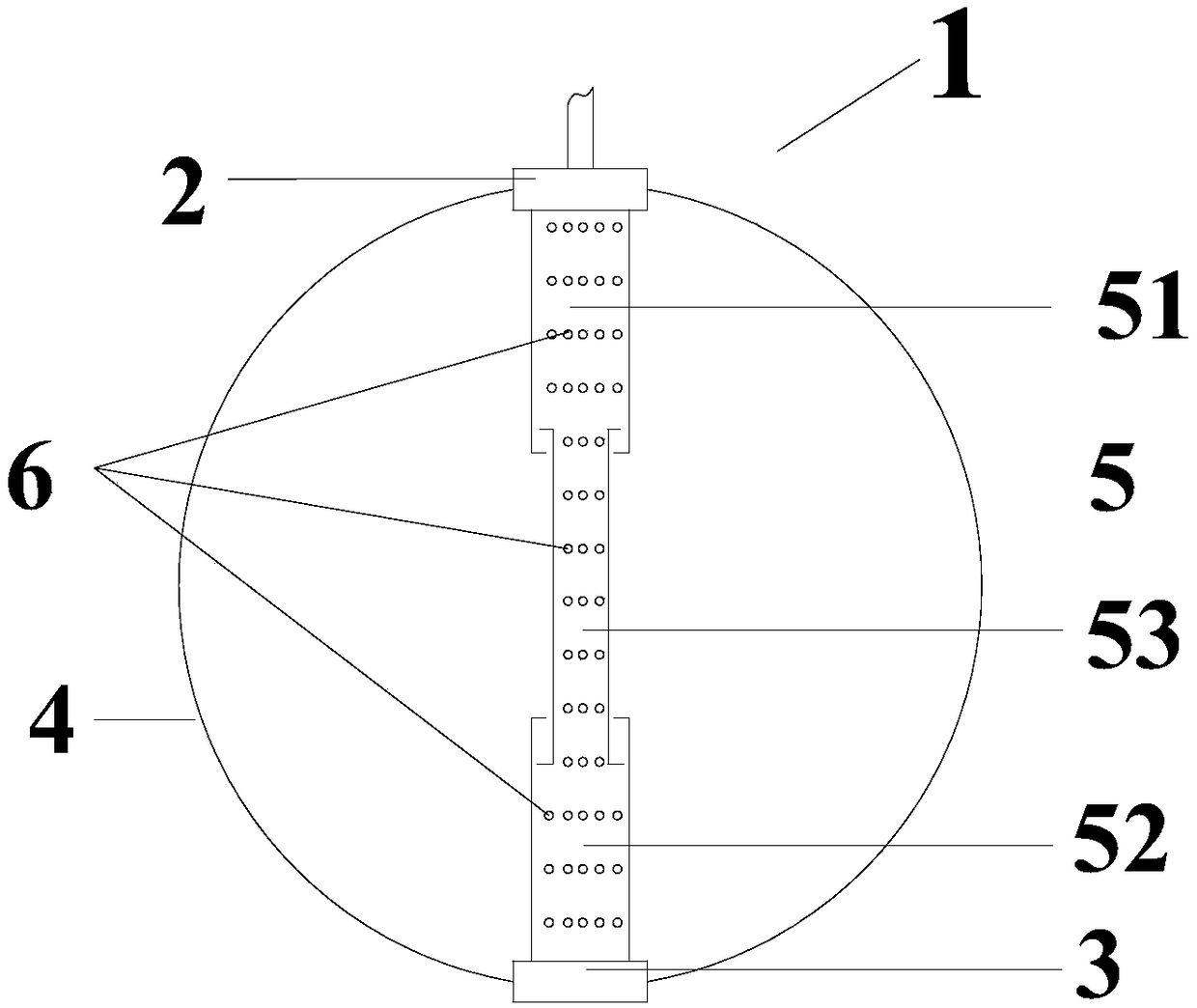

Self-lubricating oil extraction rod oil storage bag

An oil storage bag and oil cylinder technology, which is applied in the directions of container, packaging, transportation and packaging, can solve the problems of high energy consumption, asymmetry of the upper and lower flanges of the oil storage bag, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 (A): The material used for the body is silicone rubber.

[0041] Embodiment one (B): the material used for the body is ethylene-propylene rubber.

[0042] Embodiment 1 (C): The material used for the body is modified nylon-66, and the preparation method of the modified nylon-66 is:

[0043] In the reactor, add 100 grams of epoxy resin E44, 0.22 mol of 1-dodecylamine, 700 ml of propylene glycol methyl ether and 300 ml of dimethyl sulfoxide in sequence, and raise the temperature to 100 ° C for 24 hours under the protection of nitrogen. After the reaction, , the reaction solution was poured into water to obtain a large amount of white product polyetheramine.

[0044] After fully mixing 10 grams of nylon-66 and 2 grams of the above polyetheramine in a mixer, modified nylon is obtained;

[0045] Example 1 (D): In the reactor, 100 grams of epoxy resin E44, 0.11 mol of 1-dodecylamine, 0.11 mol of benzylamine, 700 ml of propylene glycol methyl ether and 300 ml of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com