Device for removing freeze-adhered coal on surface of belt

A technology of freezing and sticking belts, which is applied in the field of devices for cleaning the frozen coal on the surface of the belt, which can solve the problems of difficult cleaning of coal powder, short service life, and easy wear and tear of scrapers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

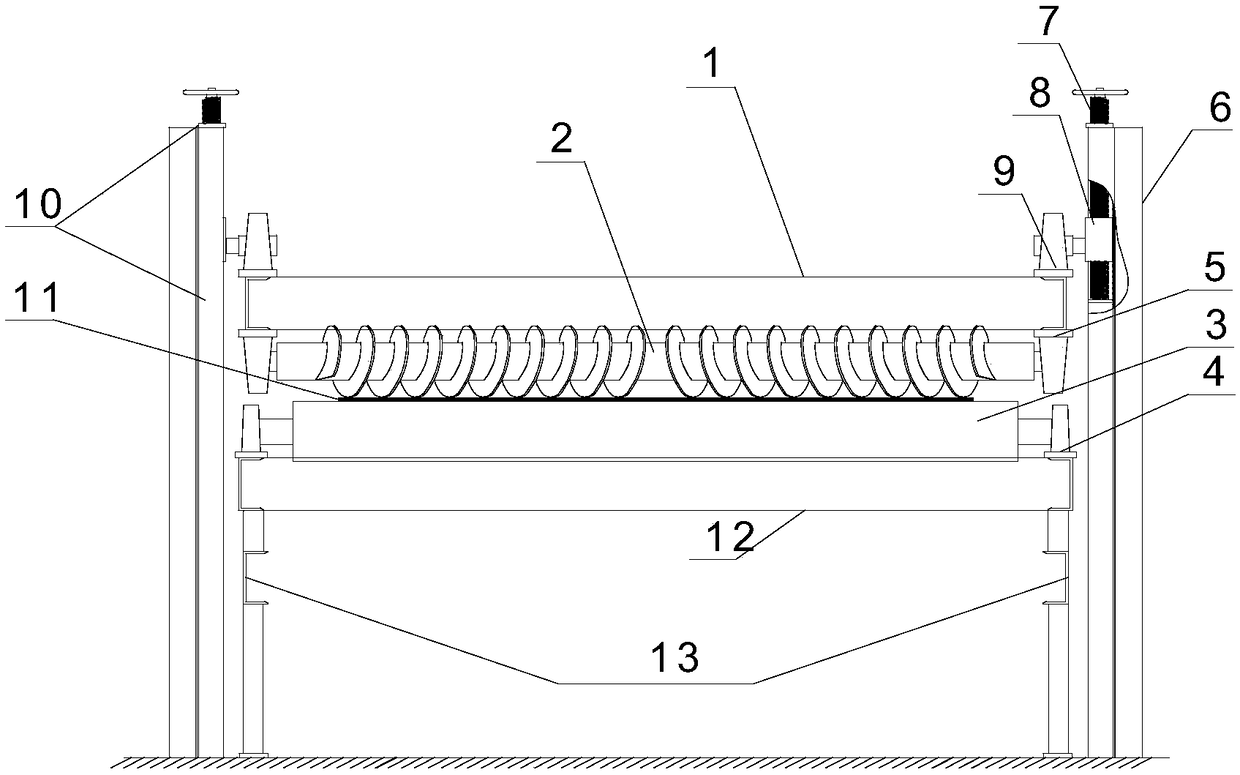

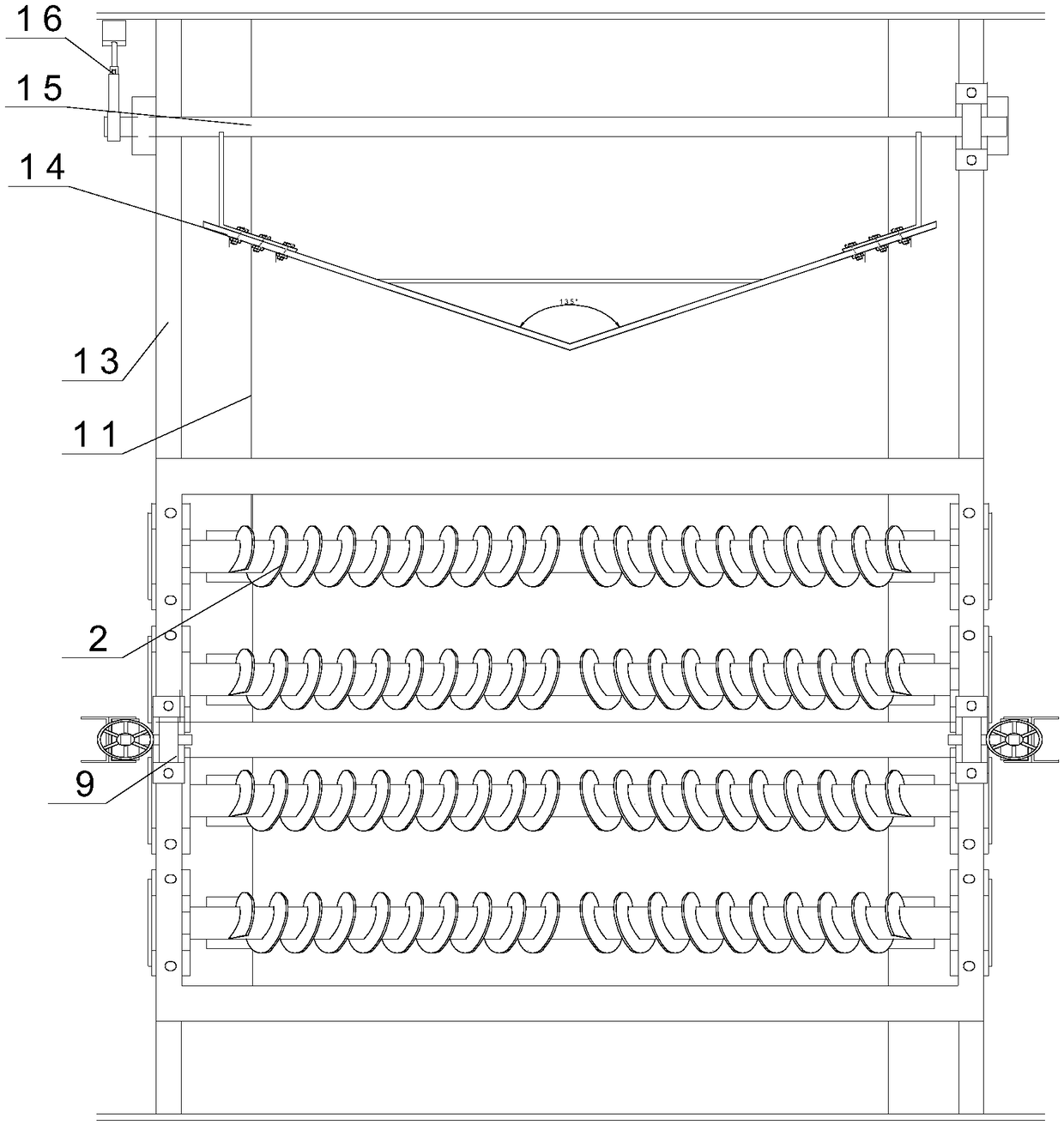

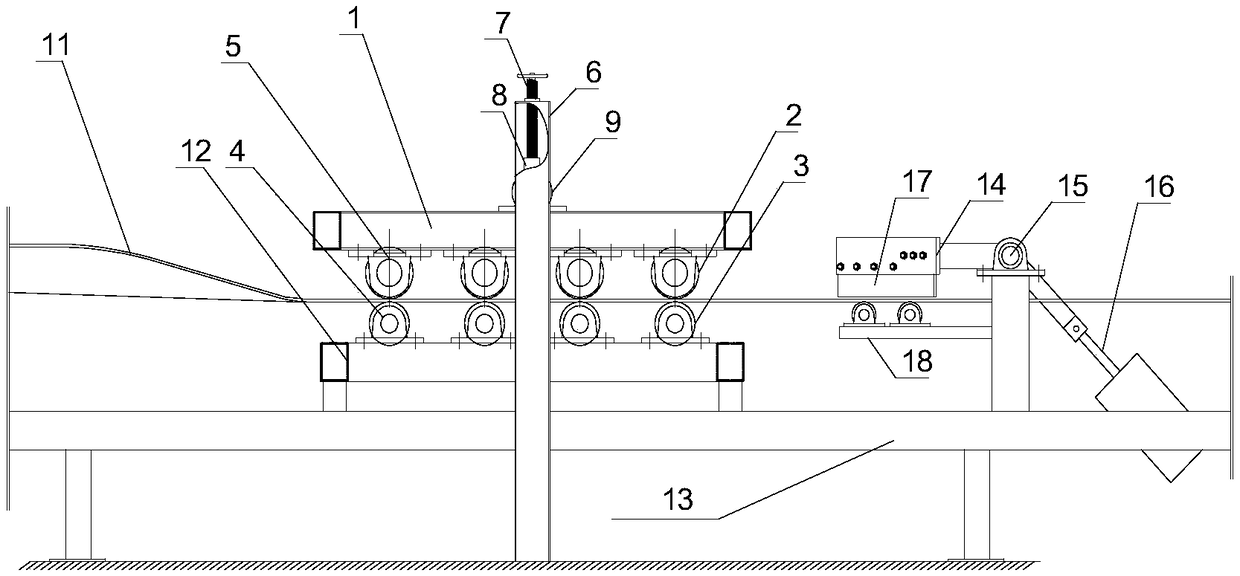

[0015] Such as image 3 As shown, a device for cleaning frozen coal on the surface of the belt includes a stripping mechanism and a cleaning mechanism. The cleaning mechanism is located at the rear of the stripping mechanism. 3. Support roller support 12, support roller bearing 4, compression adjustment mechanism support 6, lead screw 7, nut slide block 8, limit bushing 10, helical roller support connecting bearing 9, helical roller 2 is supported on both ends of the spiral On the roller bearing 5, the helical roller bearing 5 is installed on the helical roller bracket 1, and the helical roller bracket connecting bearing 9 is installed at the middle position of the helical roller bracket 1, and the helical roller bracket connecting bearing 9 is assembled with the nut slider 8, and the nut The slider 8 is fitted on the lead screw 7, and the upper end and the lower end of the lead screw 7 are respectively equipped with limit sleeves 10, the limit sleeves 10 are fixed on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com