Energy consumption support of lateral pulling and pressing type

An energy-dissipating support and lateral technology, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve the problems of reduced energy-dissipation capacity, loss of restraint and anti-buckling effect of constrained concrete, and achieve sufficient energy consumption of the structure. , The effect of reducing earthquake response and high utilization rate of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

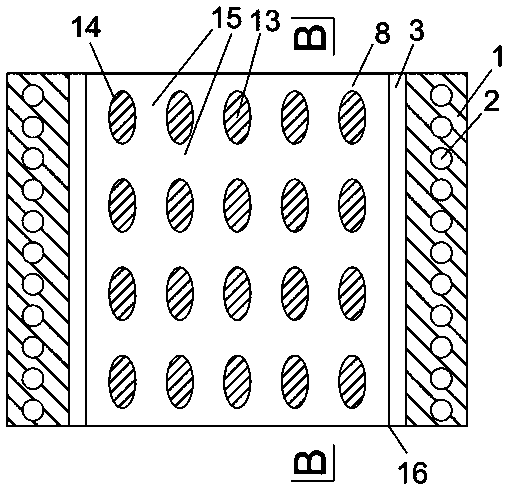

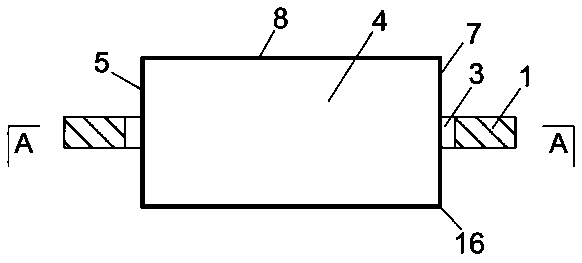

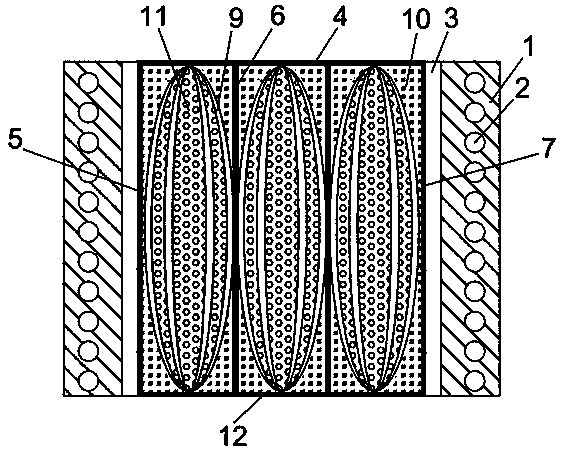

[0023] Example: such as Figure 1-Figure 6 As shown, the horizontal tension-compression energy-dissipating support includes connecting plate 1, connecting plate screw hole 2, fixed end plate 3, upper energy-dissipating plate 4, left energy-dissipating plate 5, energy-dissipating soft steel plate 6, and right energy-dissipating plate 7 , energy-dissipating steel plate 8 with elliptical holes inside, arc-shaped energy-dissipating steel plate 9, elastic bonded filling material 10, foamed aluminum energy-dissipating material 11, lower energy-dissipating plate 12, foamed aluminum plate 13, internally equipped with elliptical holes 14, energy-consuming Energy ribs 15 and energy dissipation parts 16;

[0024] In the structure of the horizontal tension-compression energy-dissipating support, connecting plates 1 are arranged at the left and right ends of the structure respectively, and several connecting plate screw holes 2 are provided on the connecting plate 1, and an energy-dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com