Lever-type oil pumping unit

A pumping unit and lever-type technology, applied in the field of machinery, can solve the problems of heavy equipment weight, inconvenient transportation, and high price of industrial electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

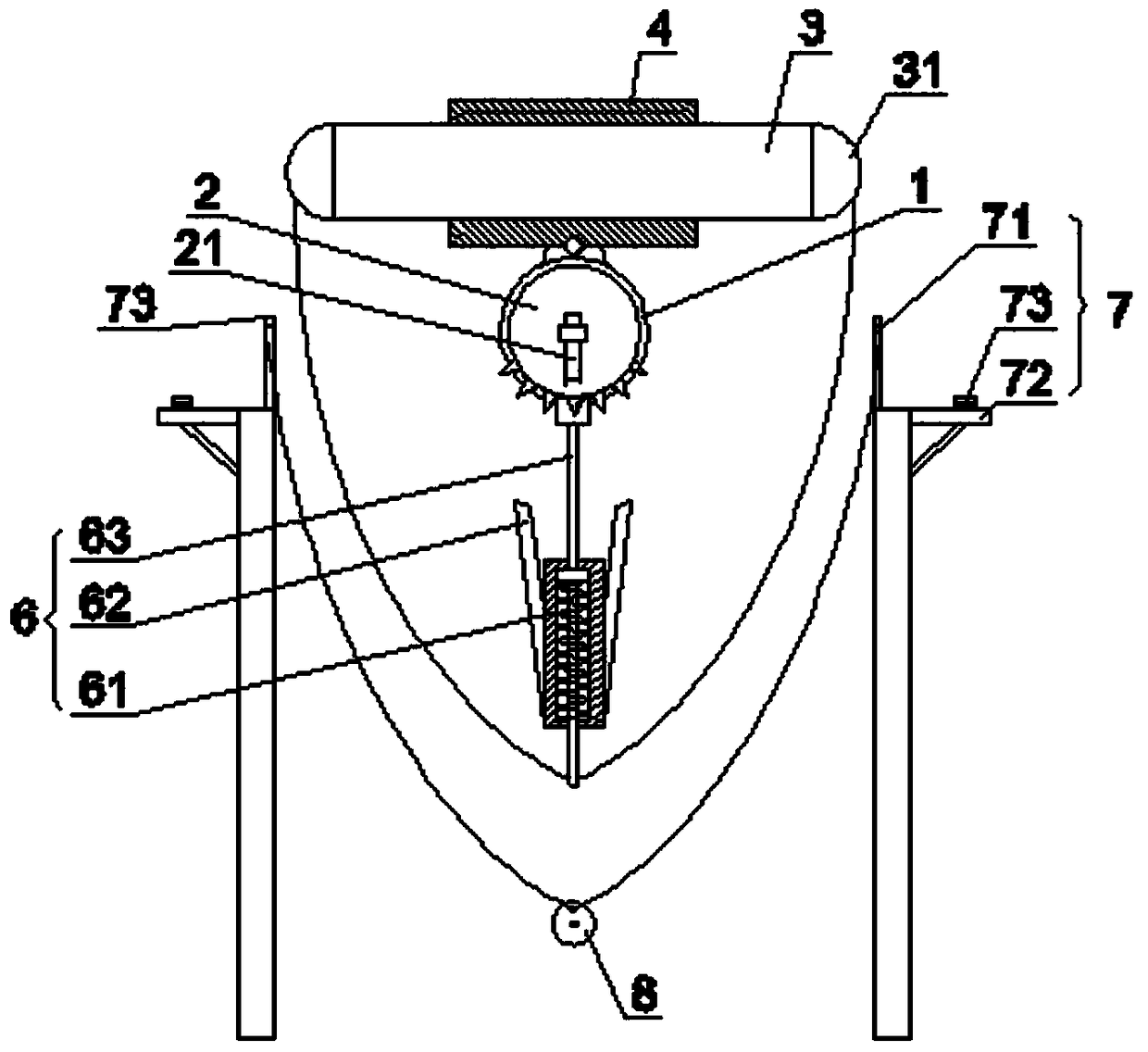

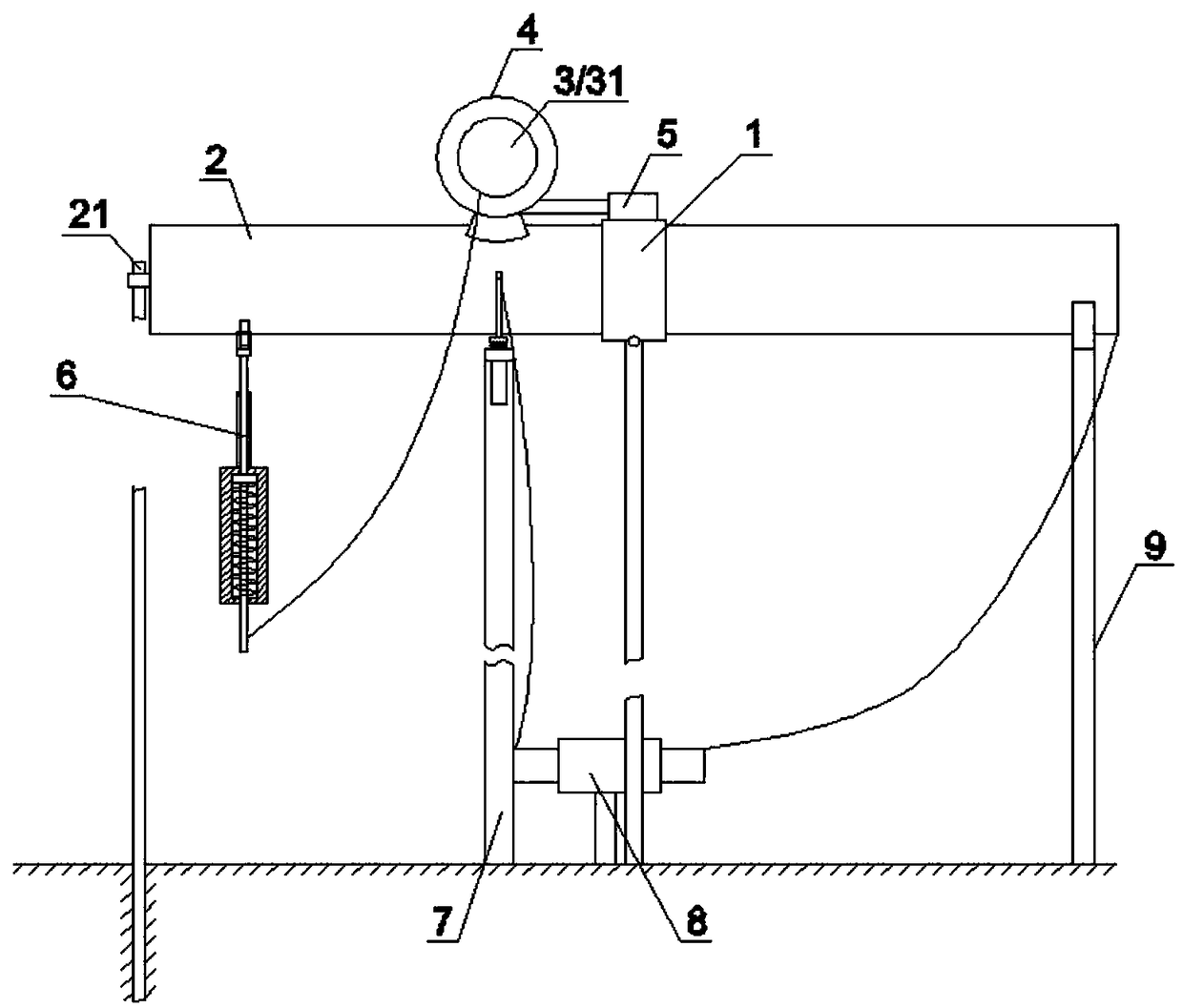

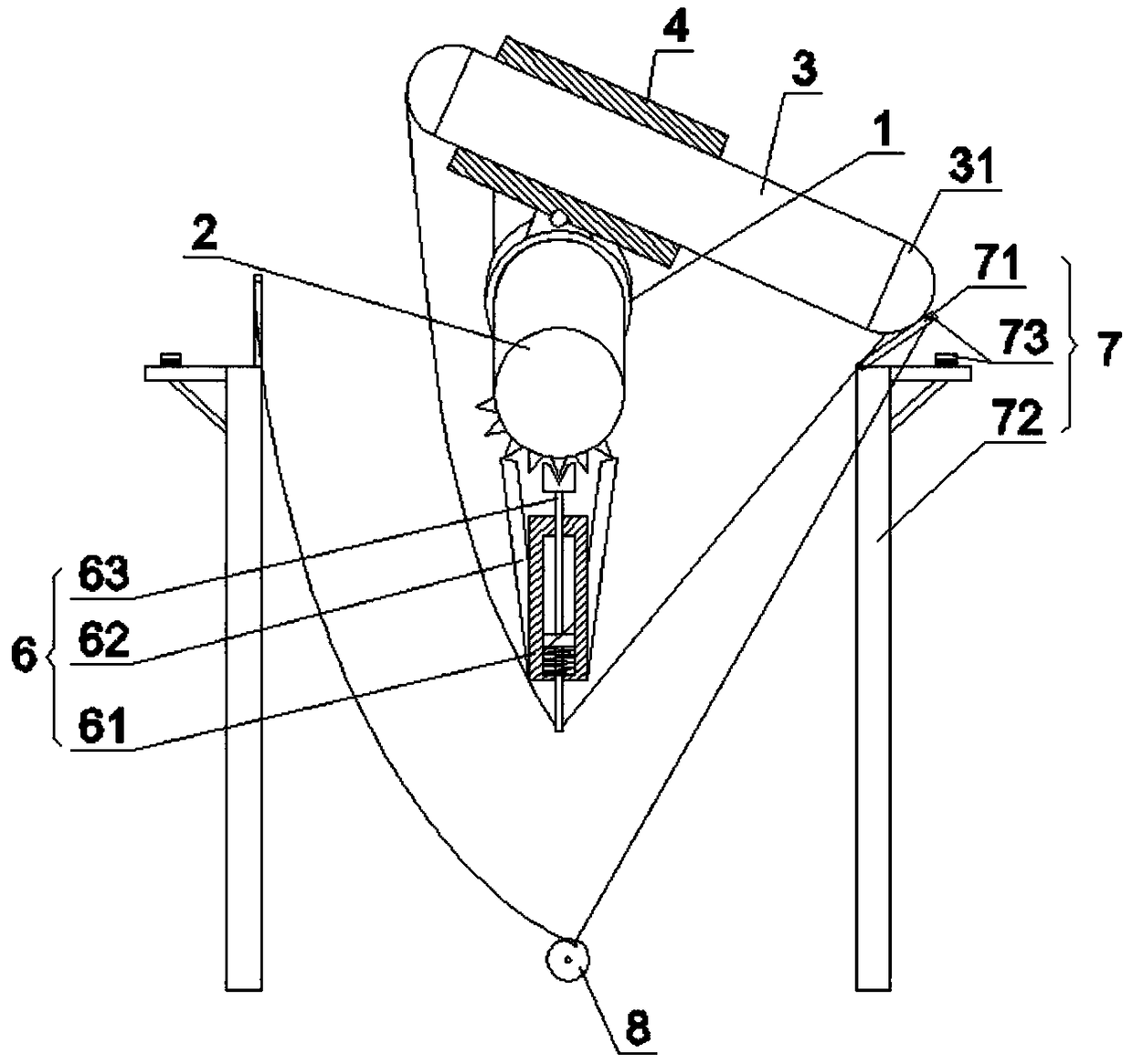

[0024] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the lever pumping unit proposed according to the present invention , as detailed below.

[0025] Such as figure 1 , figure 2 , image 3 As shown, a lever pumping unit includes:

[0026] Frame 1, main beam 2, sub beam 3, slide rail 4 and motor 5;

[0027] Due to the large load-bearing capacity of the above-mentioned frame 1, the above-mentioned frame 1 can be used as an anti-dumping measure according to the actual use. It is common to use brackets or wind ropes to form a triangular structure, which has better stability and prevents the above-mentioned main beam 2 from falling. And the center of gravity of the above-mentioned subbeam 3 changes, resulting in inclination or collapse. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com