Soil chamber medium replacement method for shield tunneling machine in freezing process

A freezing process, shield machine technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as a lot of manpower, material resources and time, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

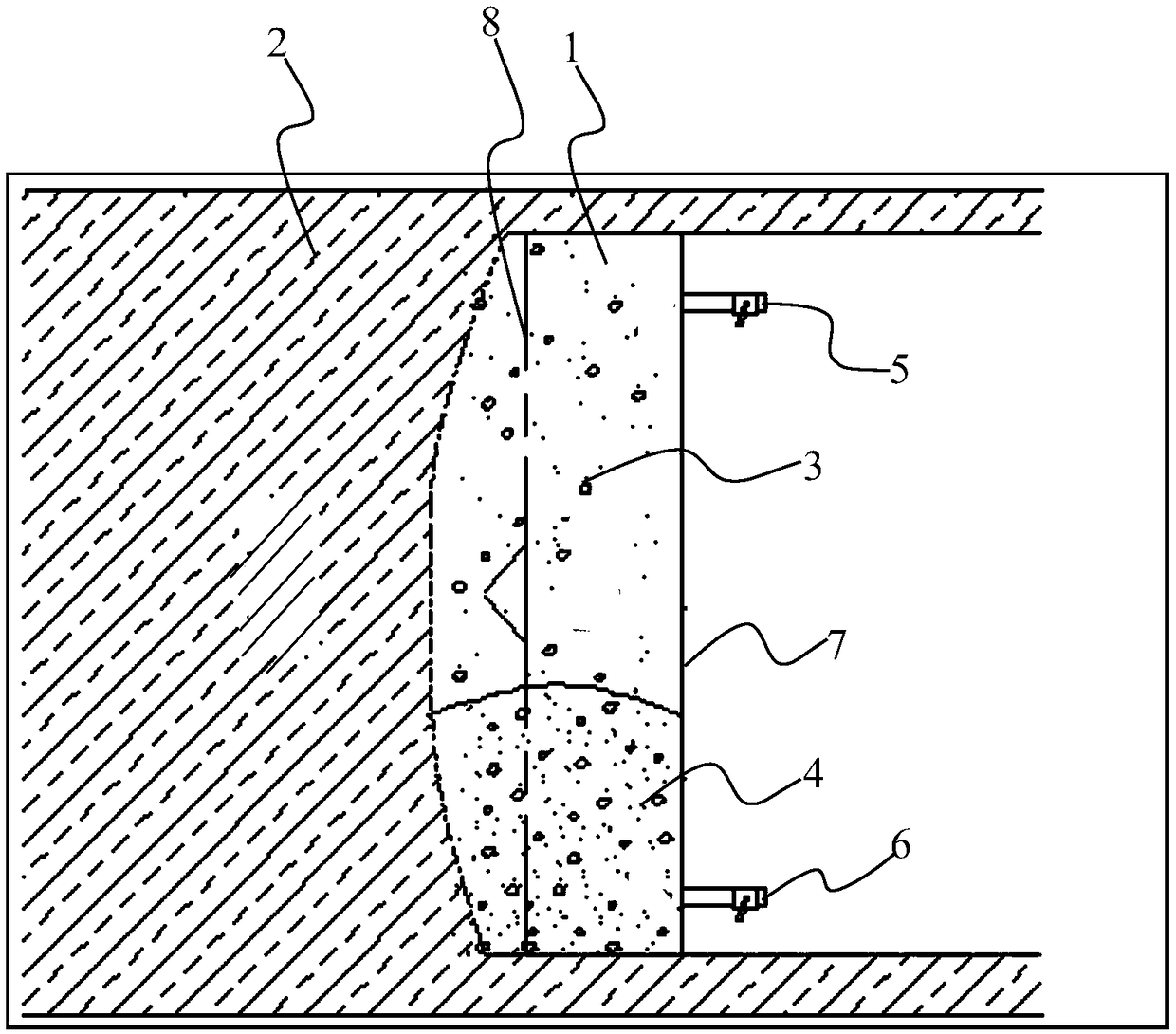

[0022] refer to figure 1 , the invention is a medium replacement method for shield machine soil bins in the freezing process, comprising the following steps:

[0023] a. The shield machine is stopped, and the bentonite slurry 4 is injected into the soil bin 1, and the dregs and mud mixed slurry 3 in the soil bin 1 is discharged at the same time, so that the bentonite slurry 4 replaces the dregs and mud mixed slurry 3;

[0024] b. Freezing the external soil body 2, and monitoring the pressure change in the soil bin 1;

[0025] c. When the frozen intersecting circle on the cutter head 8 is initially formed, gas is introduced into the soil bin 1, and the bentonite slurry 4 in the soil bin 1 is discharged at the same time to realize gas replacement of the bentonite slurry 4.

[0026] In this freezing process, the medium replacement method of the shield machine soil bin is to first use the bentonite slurry 4 to replace the mixed slurry 3 of the muck mud in the soil bin 1, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com