Wind turbine blade

A technology of wind turbine blades and blades, which is applied to wind engines, wind engines consistent with the wind direction, and control of wind engines. It can solve problems such as inconvenience, difficulty in starting at low wind speeds, and low utilization rate of wind energy, so as to improve economic benefits. , Wind energy utilization rate improvement, wind energy protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

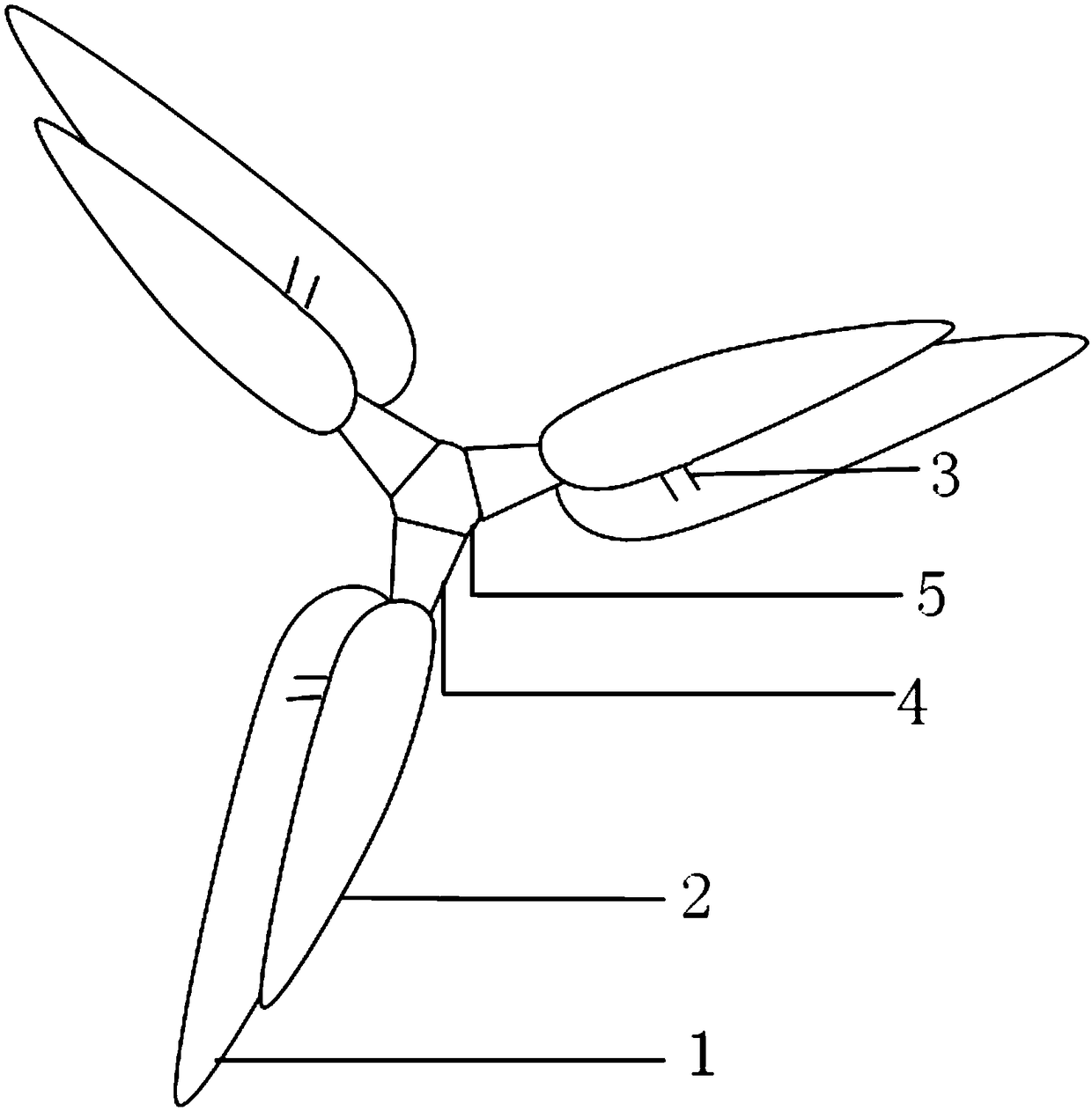

[0019] In this embodiment, the blade of a horizontal-axis wind power generator is taken as an example to describe the brand-new aerodynamic layout blade in detail.

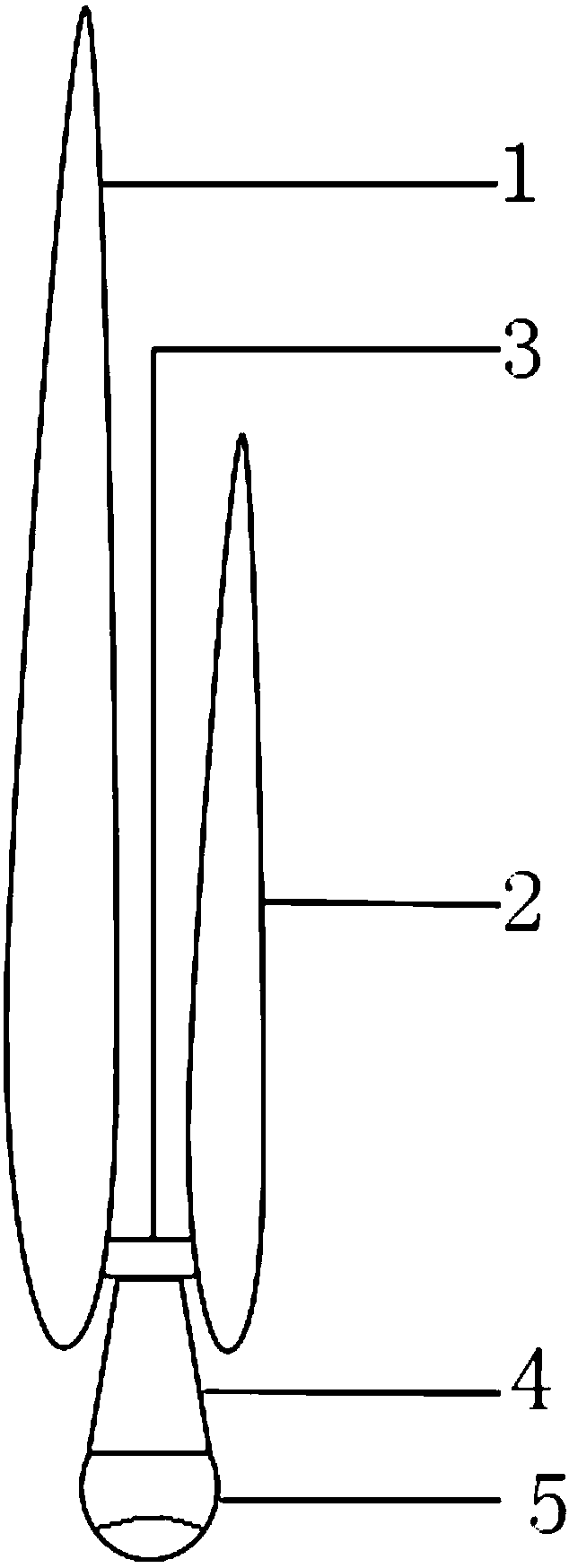

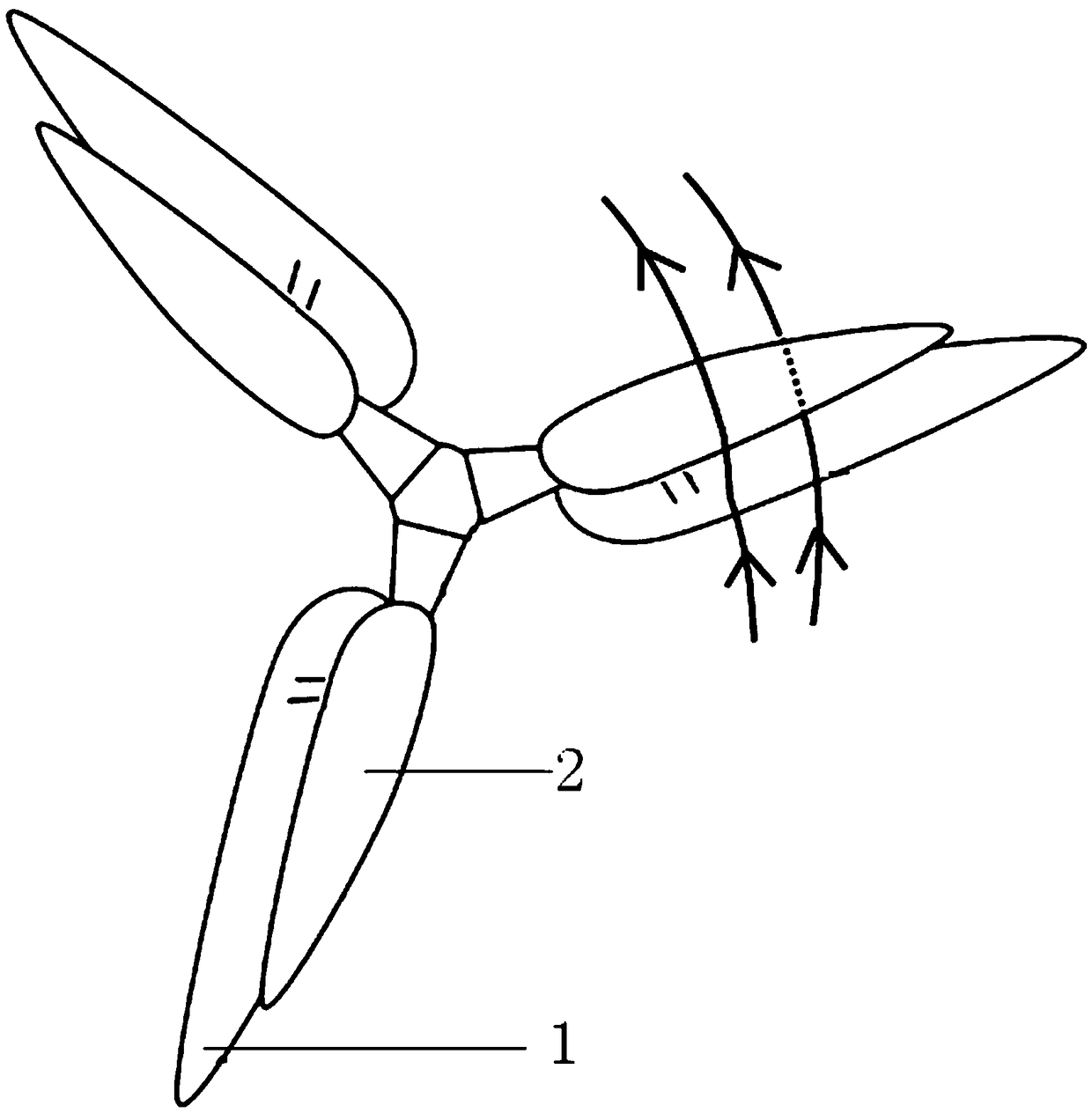

[0020] Refer to attached figure 1 with 2 As shown, the blades of the wind turbine in this embodiment include three groups of blades uniformly arranged in the radial direction with the hub as the center, each group of blades includes a main blade 1 and an auxiliary blade 2, and the auxiliary blade 2 is smaller than the main blade in length and width. 1, and the auxiliary blade 2 is arranged parallel to the upwind direction of the main blade 1.

[0021] A preferred embodiment is that the auxiliary blade 2 is arranged in parallel with the main blade 1, and the front edge of the auxiliary blade 2 is arranged in an offset direction toward the rear edge of the main blade 1, such as figure 1 shown.

[0022] A more optimal embodiment is that the auxiliary blade 2 adopts a thin wing blade.

[0023] The main blade 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com