Milled oblate ball cage and manufacturing method thereof

A flat square, ball cage technology, applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of stuck service life, poor control performance, long processing cycle, etc., to improve the service life and ensure Switch freely and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

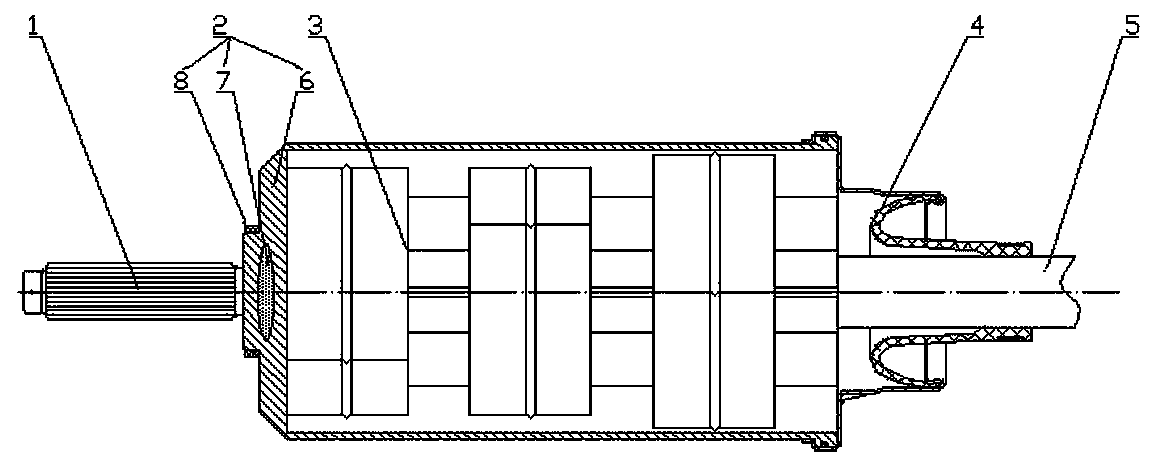

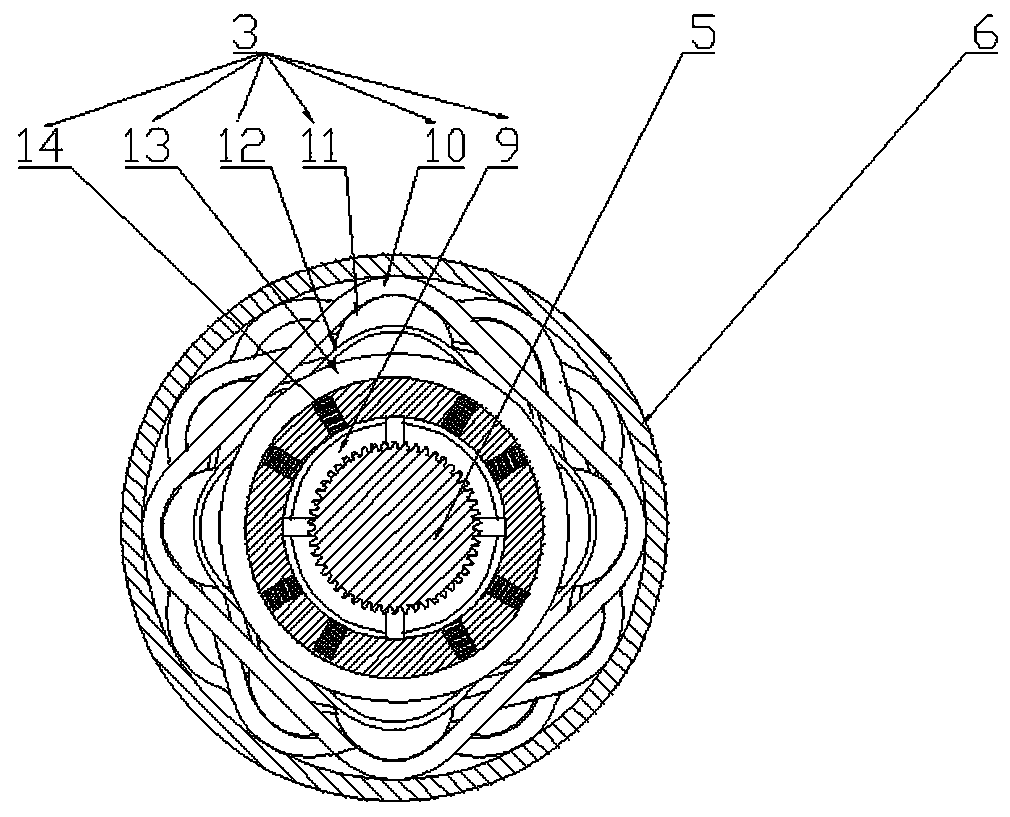

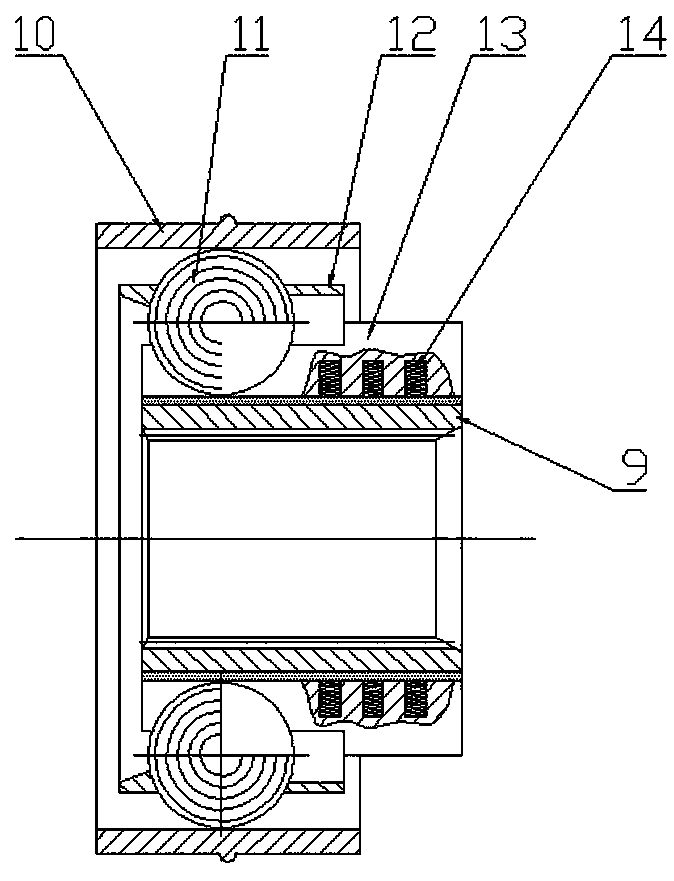

[0038]Embodiment: As shown in the figure, a milled flat square ball cage and its manufacturing method include a ball cage seat 2, the ball cage seat 2 includes a base frame 6, the base frame 6 is provided with a road condition detector 7, and the end surface of the base frame 6 is There is a data collection ring 8 socketed with the base frame 6, and the data collection ring 8 is wirelessly connected to the road condition detector 7; the bottom end of the ball cage seat 2 is provided with an input shaft 1 integrated with the ball cage seat 2, The end surface of the ball cage seat 2 is provided with a dustproof cover 4 which is fastened to the ball cage seat 2, and the ball cage seat 2 is provided with 3 sets of ball cage assemblies 3 arranged concentrically and evenly staggered. The ball cage assembly 3 includes a flat square The spherical cage body 10, the flat square spherical cage body 10 is provided with a flat square star-shaped sleeve 13, and between the flat square star-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com