A vibration damping ring for high-speed train wheels based on phononic crystals

A technology of phononic crystals and train wheels, applied in vibration suppression adjustment, springs/shock absorbers, mechanical equipment, etc., can solve problems such as unsatisfactory vibration and noise reduction effects, extend the number of periodic structure cycles, and improve vibration isolation effect, the effect of improving the vibration isolation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

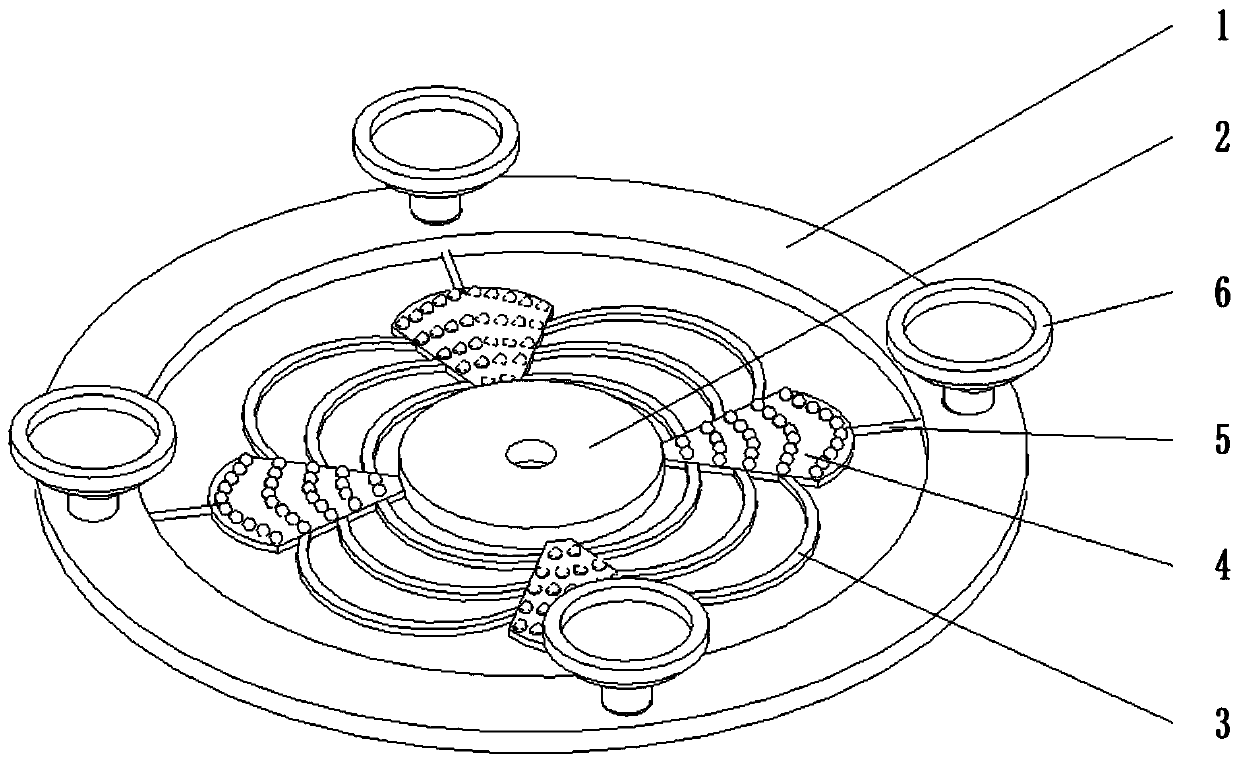

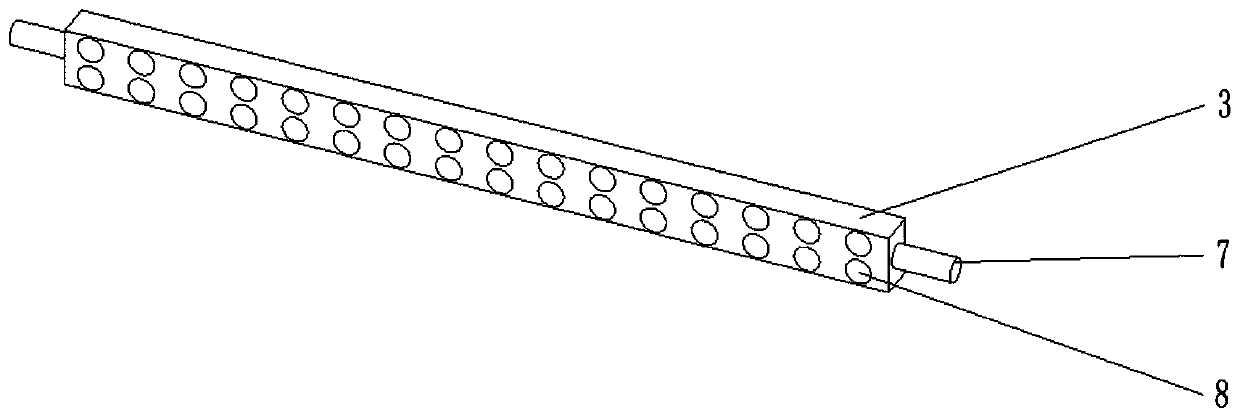

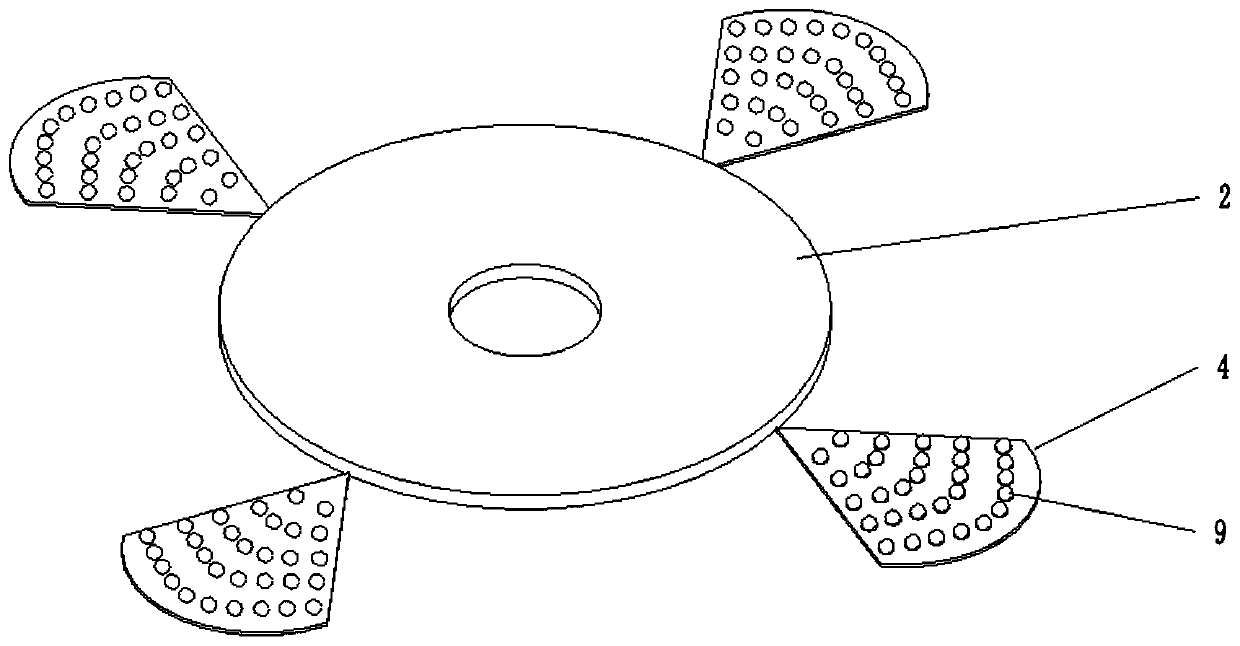

[0026] Specific implementation mode one: the following combination Figure 1-Figure 3 Describe a phononic crystal-based high-speed train wheel vibration damping ring in this embodiment, which includes an outer ring 1, an inner ring 2, a Bragg type phononic crystal vibration isolation ring 3, and a local resonance type phononic crystal vibration isolation component 4 , connecting rod 5, vibration transmission ring 7, vacuum suction cup 6;

[0027] Among them, the Bragg-type phononic crystal vibration isolation ring 3 is processed with a circular hole-shaped groove 8 , and annular scatterer sheets are periodically arranged in the groove 8 .

[0028] Wherein, the base body of the local resonance type phononic crystal vibration isolation component 4 is an arc-shaped thin-layer structure, and circular grooves are processed on the thin-layer structure, and 9 spherical local resonance units are periodically arranged in the grooves.

[0029] The inner ring 2 and the outer ring 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com