Spectral confocal measurement system and method for large-scale measurement

A spectral confocal and measurement system technology, applied in the field of optical displacement measurement, can solve the problems of small measurement position range, reduced measurement accuracy, time-consuming and labor-consuming, etc., to increase the position range, the method is convenient to operate, and the measurement accuracy is guaranteed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

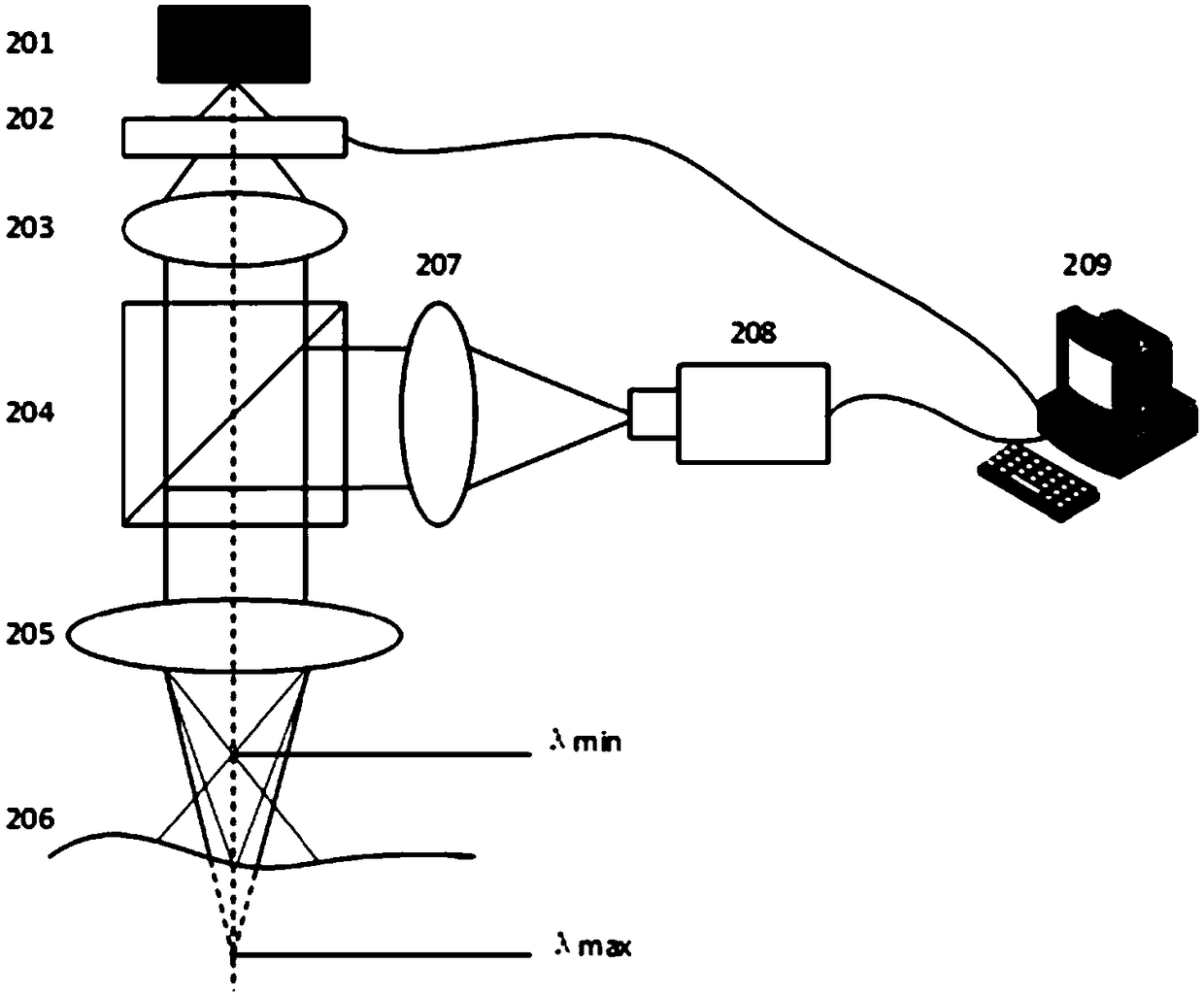

[0029] see figure 1 and figure 2 , the spectral confocal measurement system of this embodiment includes a light source component, a spectral confocal measurement component, a signal receiving component and a processor.

[0030] The light source assembly includes a broadband light source 201 , a tunable filter 202 and a collimator lens 203 . The wide-spectrum light source 201 can be a halogen lamp, or a laser-driven wide-spectrum light source. The tunable filter 202 is used to widen the spectral beam into a narrowband beam with a specific central wavelength. The collimator lens 203 is used to collimate the beam emitted by the tunable filter 202 .

[0031] The spectral confocal measurement component includes a beam splitter 204 and a dispersion objective lens group 205 . The beam splitter 204 makes the light beam emitted from the light source component propagate along the original path, and reflects the light beam reflected from the surface of the object 206 to be measured ...

Embodiment 2

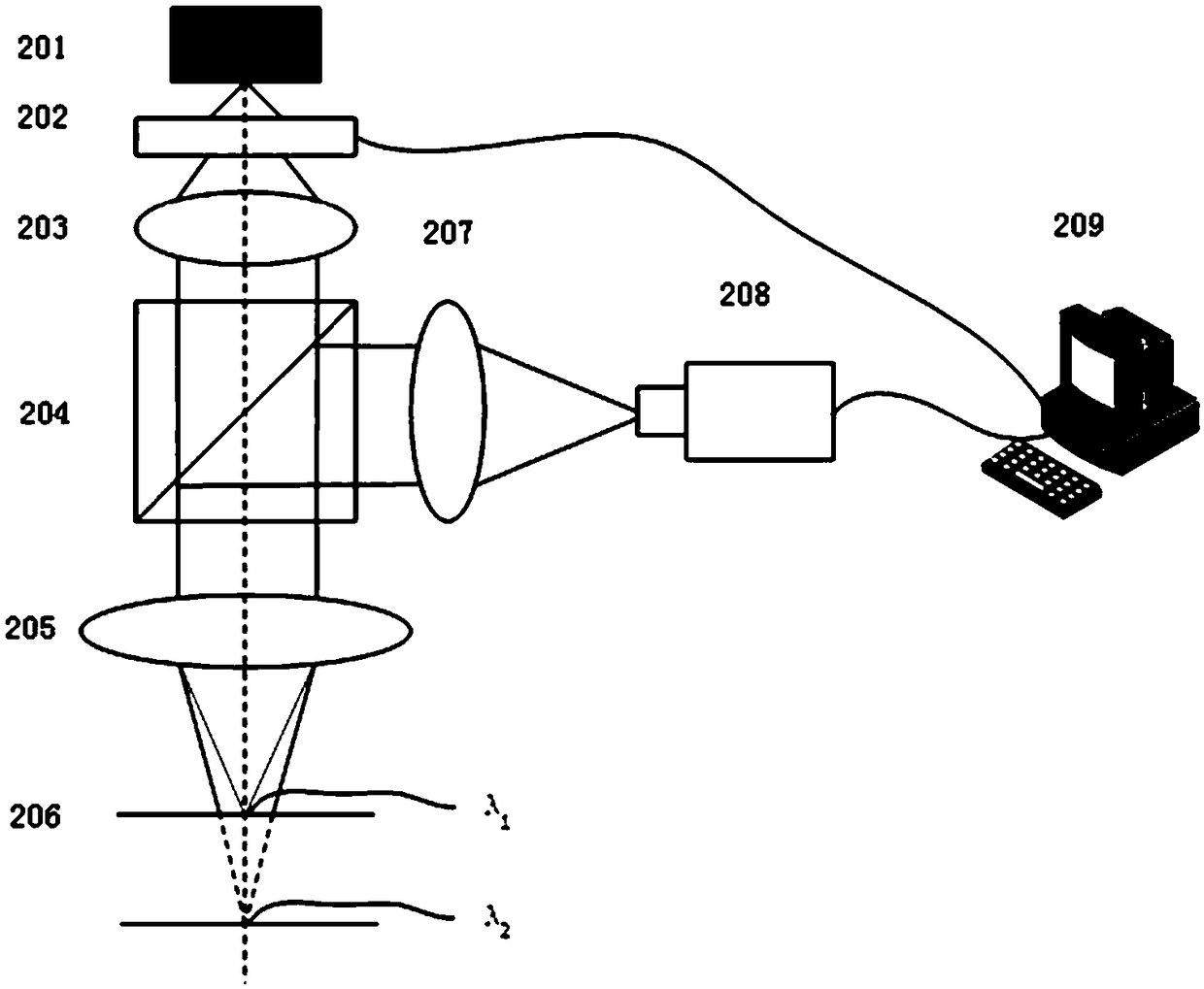

[0042] see image 3 , the structure of the spectral confocal measurement system of this embodiment is the same as that of Embodiment 1, the difference is that the object 206 to be measured in this embodiment is a material with good light transmittance, and the light beam dispersed by the dispersion objective lens group 205 can pass through the object to be measured The measuring object 206 reaches the lower surface of the measuring object 206 .

[0043] In the first measurement, the beam of the wide-spectrum light source is dispersed by the dispersive objective lens group 205 and then emerges, and the upper and lower surfaces of the object to be measured 206 will simultaneously make the monochromatic light of a specific wavelength focused on it reflect back to the original path. , so that the monochromatic light energy loss of these two wavelengths is very small. The light beam reflected by the upper and lower surfaces of the object to be measured 206 is reflected to the focu...

Embodiment 3

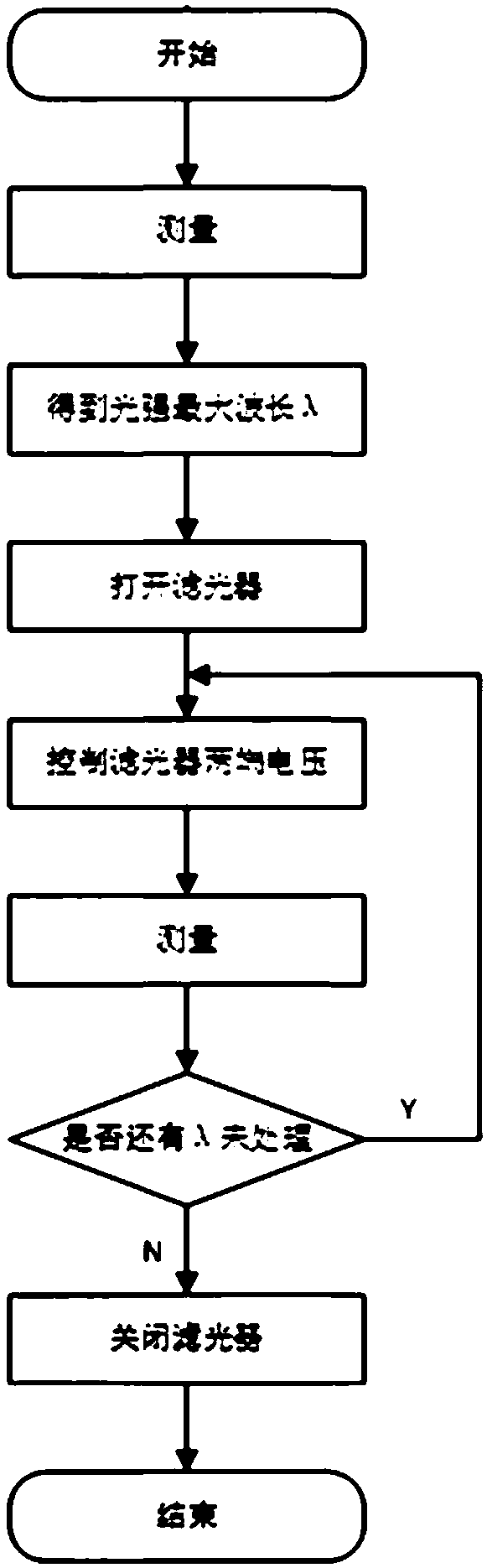

[0046] This embodiment provides a spectral confocal measurement method for large-scale measurement, which has been included in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com