On-line measurement and weighing method and device for steel and aluminum strips

A weighing scale and steel-aluminum technology, which is applied in the field of steel-aluminum strip weighing, can solve the problems of increasing work intensity, troublesome work in delivery and inventory, and troublesome operation, so as to improve weighing accuracy, ensure work quality, and reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

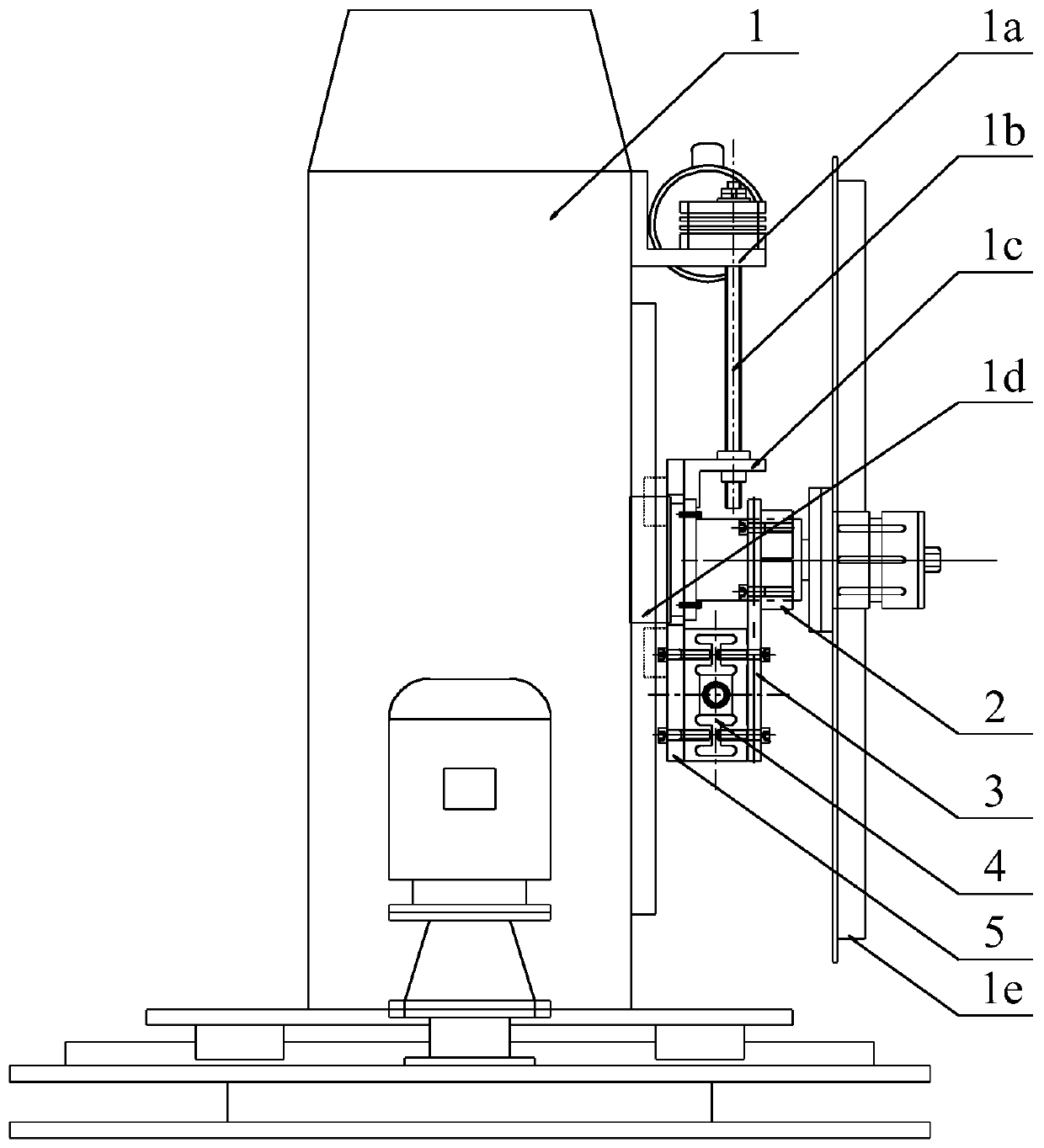

[0050] see figure 1 As shown, the transmission assembly of the tape rack 1 includes a steel-aluminum strip rotating bearing seat, a slider bearing, an L-shaped connecting plate 1c fixed on the slider bearing, a copper nut arranged on the L-shaped connecting plate 1c, and a wire The motor 1a connected with the rod 1b and the copper nut; it can be seen that, under the traction of the motor 1a, the screw rod 1b can drive the connecting plate 1c to move up and down, so as to change the steel and aluminum strip 1e on the transmission assembly according to different construction environments purpose of the location.

[0051] On this basis, see figure 1 As shown, the process of S1 includes:

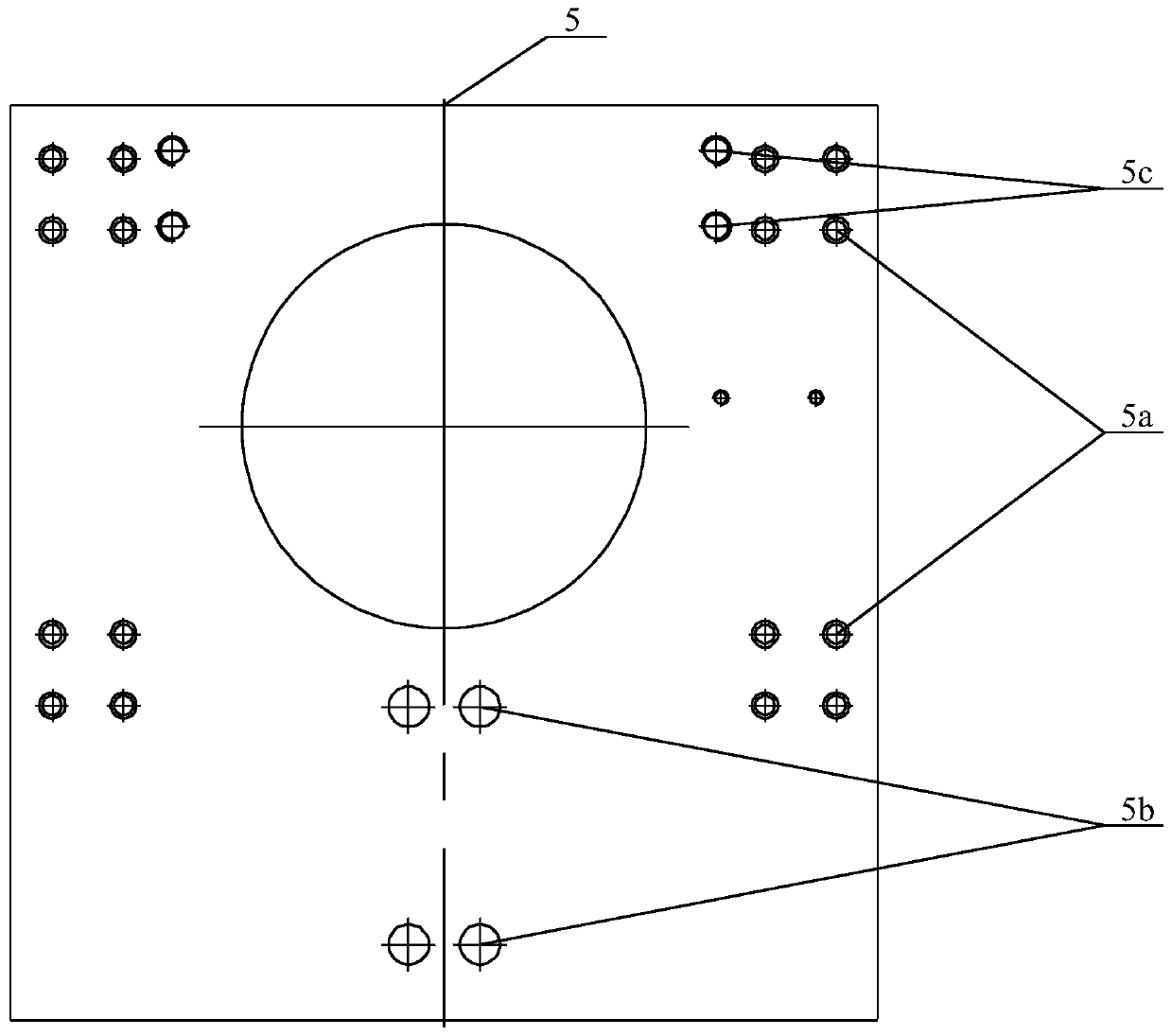

[0052] S101: see figure 1 and image 3As shown in , fix the mounting plate and the L-shaped connecting plate 1c, go to S102;

[0053] S102: see figure 1 As shown, fix the left side of the load cell 4 to the lower part of the mounting plate 5, go to S103;

[0054] S103: see figure 1 As sh...

Embodiment 2

[0058] On the basis of the first embodiment, the middle opening of the mounting plate 5 in S101, the transmission part of the steel and aluminum strip and the tension controller are all located in this opening, and do not contact with this opening, thereby avoiding dryness of weighing and further improving the weighing capacity. heavy precision.

Embodiment 3

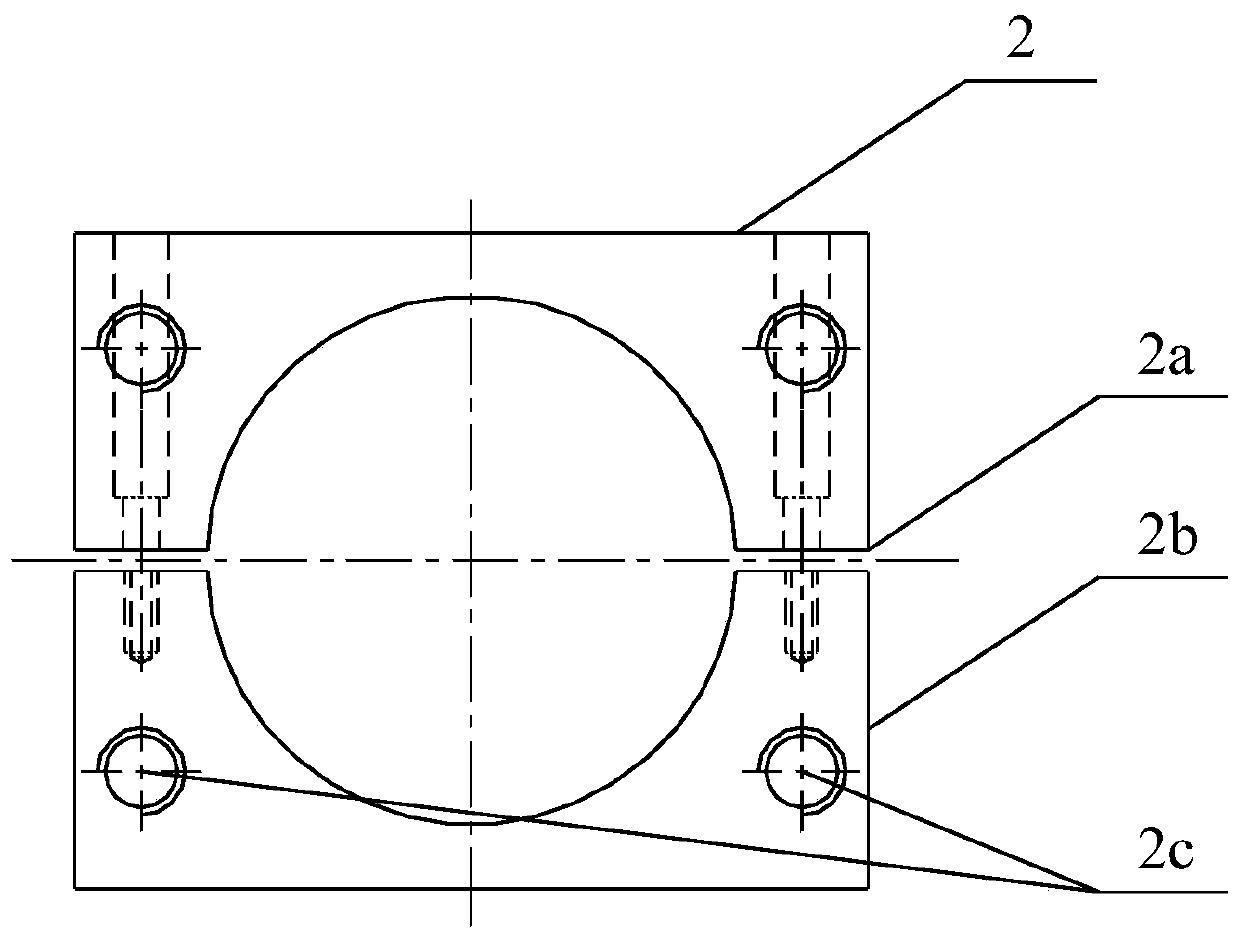

[0060] On the basis of embodiment one, see figure 2 As shown, the bearing seat fixture 2 in S104 includes an upper half fixture 2a and a lower half fixture 2b fixed on the slider bearing, and the upper part of the support plate 3 is fixed to the lower part of the lower half fixture 2b.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap