Gas sampling analysis system and sampling analysis method using same

An analysis system and gas sampling technology, applied in the direction of analysis materials, sampling devices, instruments, etc., can solve problems such as difficulty in sampling high temperature and low pressure gas sources, and achieve the effect of avoiding sample loss and leakage, reducing errors and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment the present invention is described in further detail:

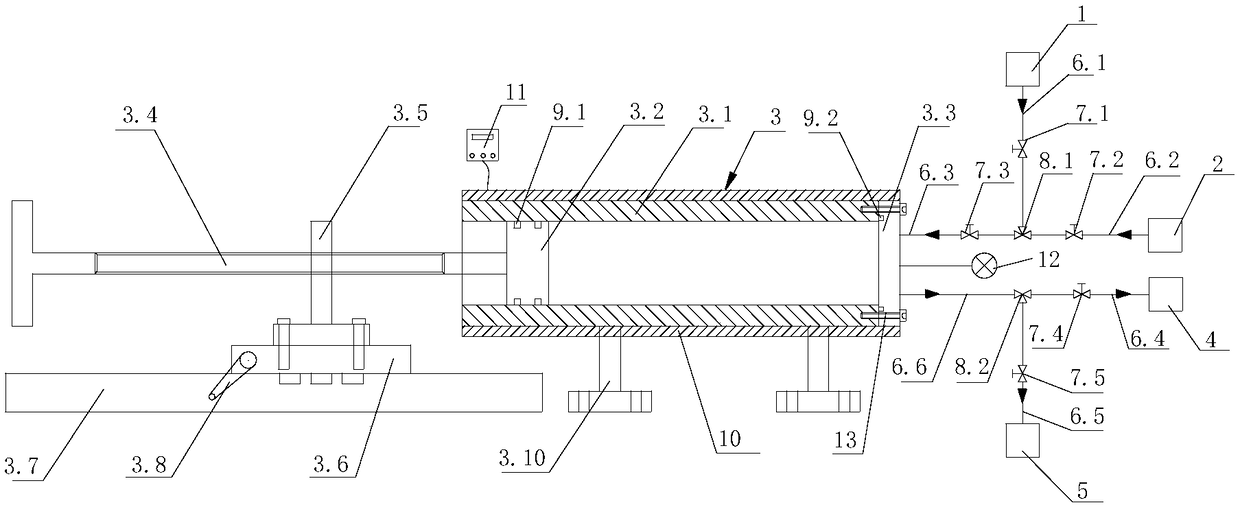

[0035] A gas sampling and analysis system as shown in the figure includes a sample gas tank 1, a nitrogen gas tank 2, a piston sample holder 3, a vacuum pump 4, and a gas analyzer 5. The engine exhaust gas and exhaust gas reformed gas can be stored in the sample gas tank 1 or other equipment emissions. The gas outlets of the sample gas tank 1 and the nitrogen tank 2 are both connected to the air inlet of the piston sample holder 3, and the gas outlet of the piston sample holder 3 is connected to the air inlets of the vacuum pump 4 and the gas analyzer 5 respectively.

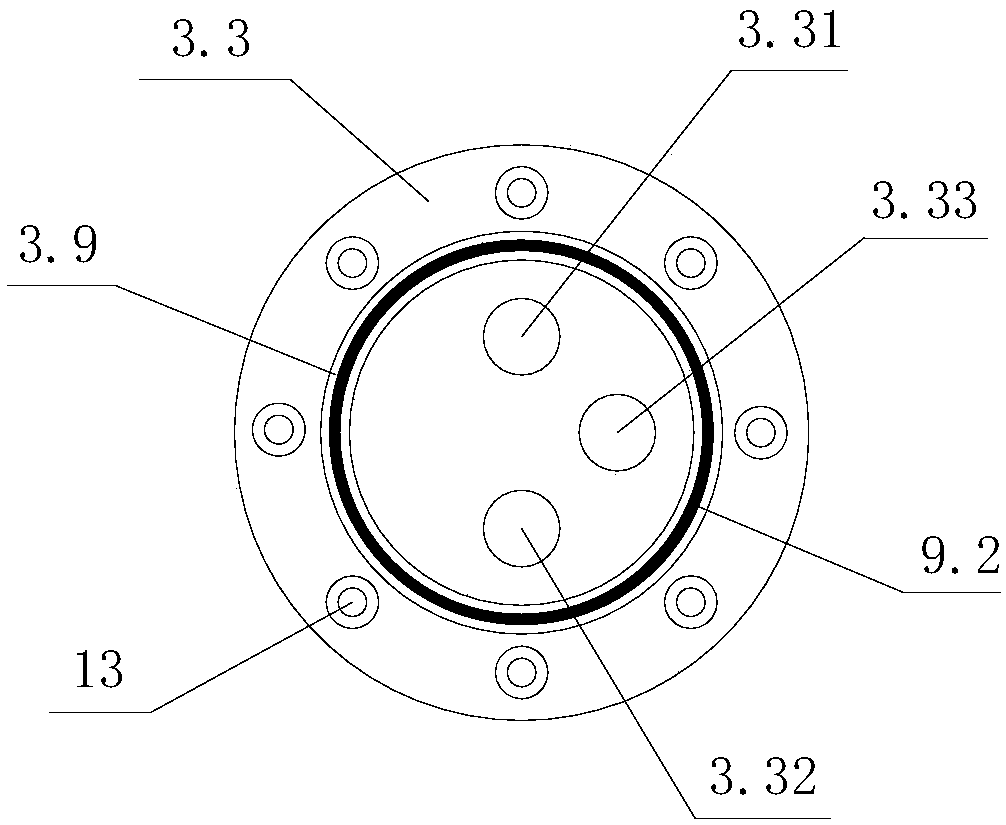

[0036] In the above-mentioned technical solution, the piston sample holder 3 includes an air storage cylinder 3.1 and a piston 3.2 which is arranged in the inside of the air storage cylinder 3.1 to slide and cooperate with it. There is a push rod 3.4 fixedly connected with the piston 3.2; the push rod 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com